-

Industry Trends/Customer Challenges

Industry Trends/Customer ChallengesThe changes of the order of small quantity in wide variety. Factory is survival of not only high cost but short lead time. How to meet?

In the digital age, furniture manufacturers must think like fashion designers to innovate and continually introduce new products to stay competitive.

The complexity of functional furniture development and production is rising, with consumers demanding higher environmental and health standards. Consequently, manufacturers must prioritize sustainable and eco-friendly sofa production methods.

Labor salary is growing and young generation requires for good walfare and working environment, cause lack of skillful and stable worker.

Affected by the raw material supply and currency exchanging rate, price of material is going up and down become the big challenge for industry.

Traditional production procedures are complicated, consuming and costing, cause both of sample development and production is slow.

-

Advantages of GBOS Solutions

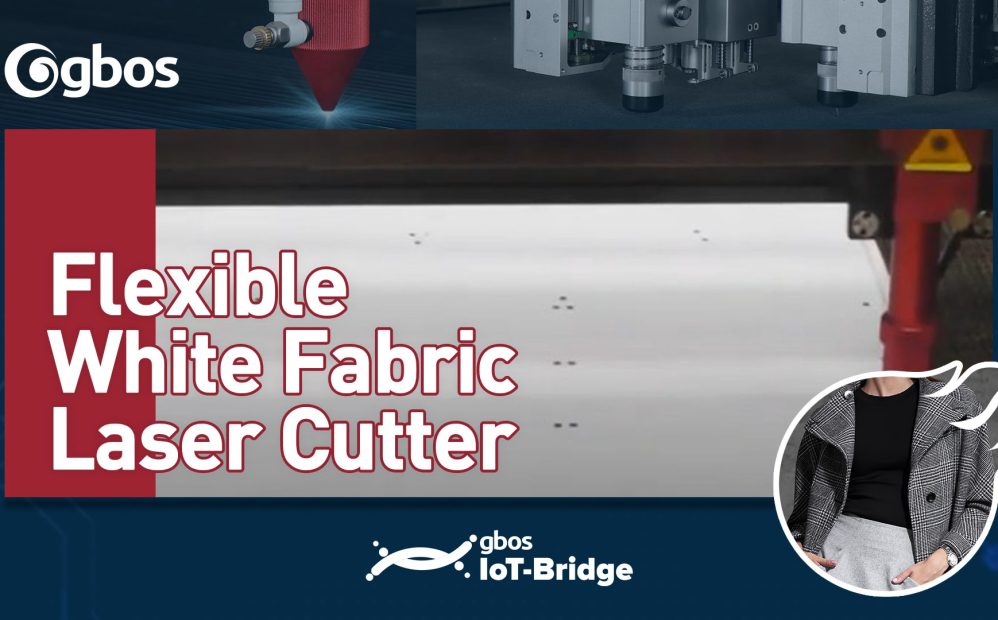

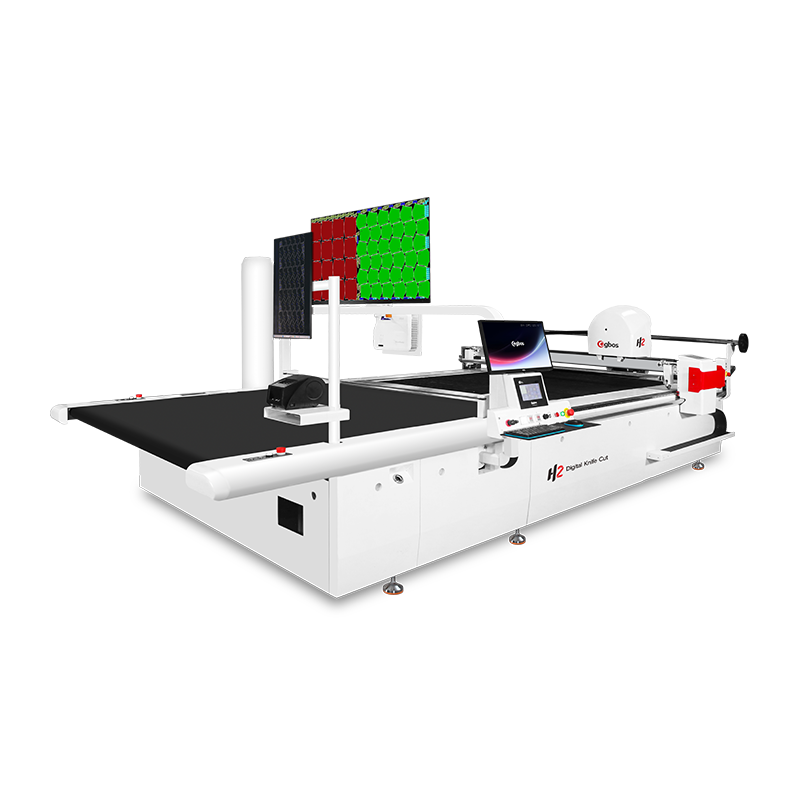

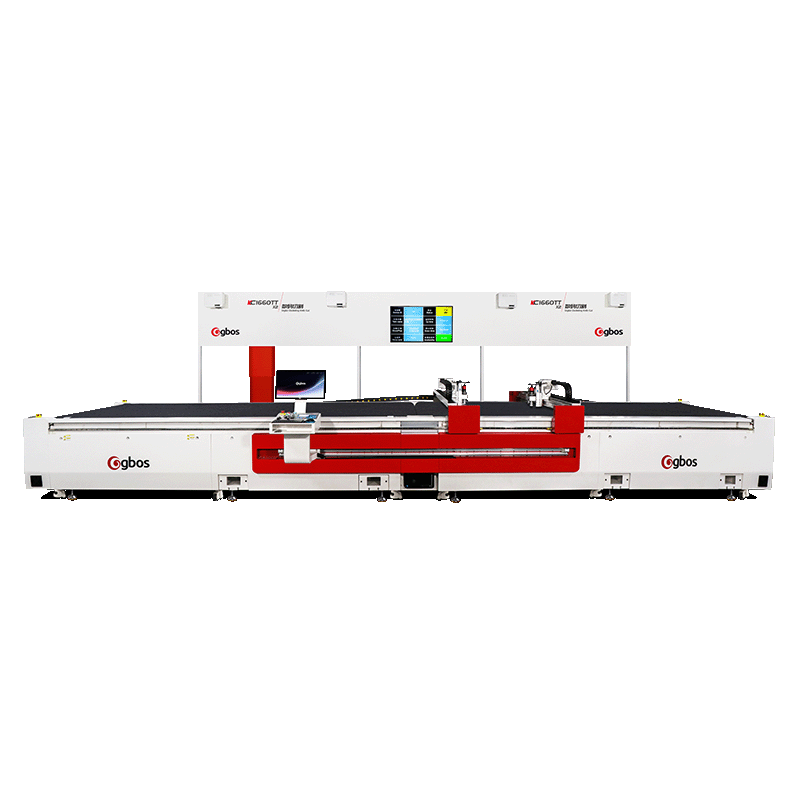

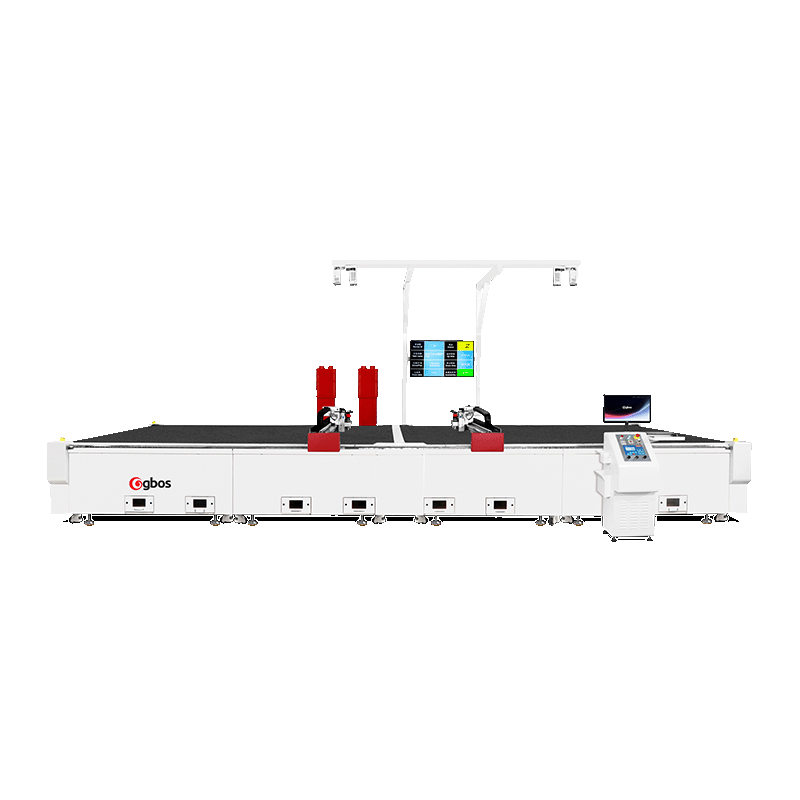

Advantages of GBOS SolutionsFully Automated: GBOS fully automated system, integrated with proprietary software, handles urgent orders efficiently without extra labor costs, meeting diverse market demands and boosting production capacity.

Digital Management: Digital production and data analytics reduce waste and optimize resource use, minimizing overall material waste.

Sustainable Development: Pollution-free digital cutting paired with digital management ensures a sustainable production process.

Reduce Costs: GBOS ITS series of products for regular materials and leather materials saving nesting function can provide the utilization of materials.

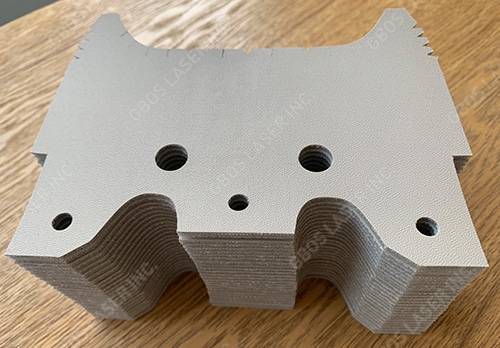

Comprehensive Solutions: Covering low, medium and high level cutting solutions, whether it is a small, diverse order or a large volume order, it can respond quickly.

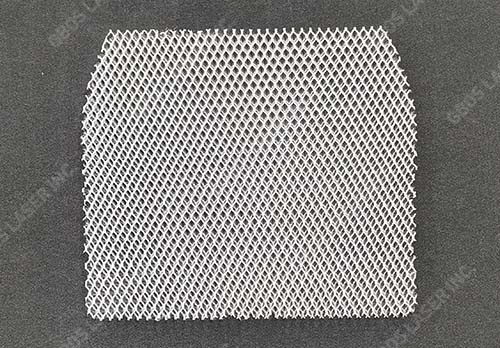

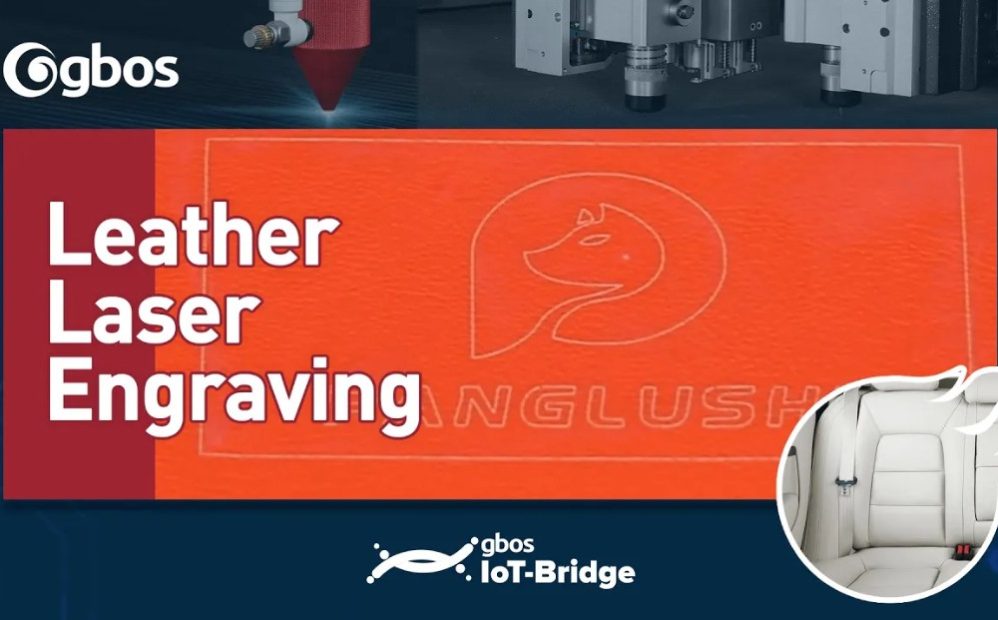

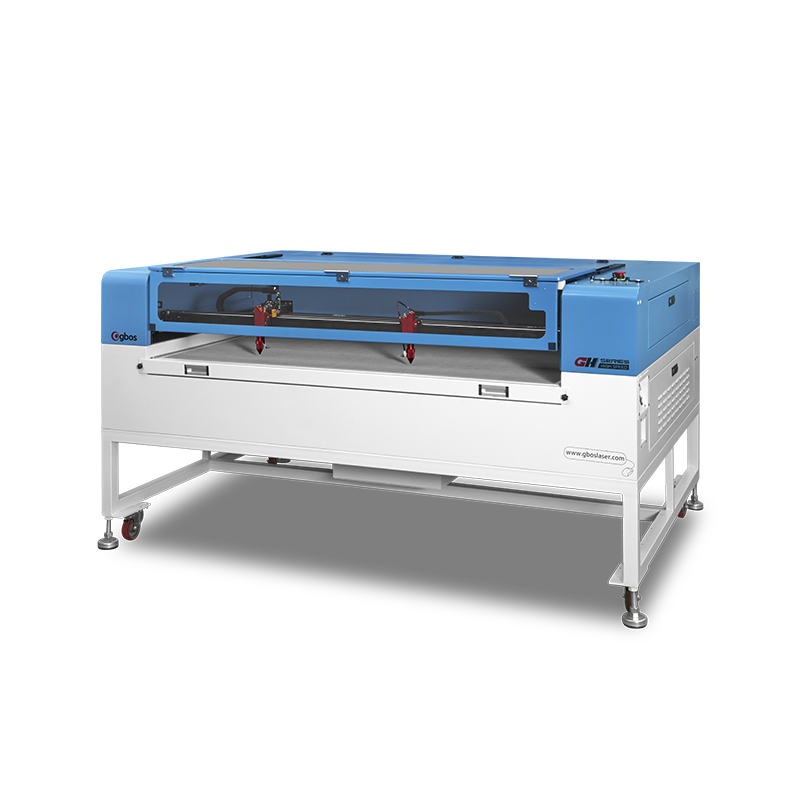

Laser Artcraft Solution: In the field of upholstered furniture on a variety of fabrics using laser technology to hollow out, punching, surface burning and other new emerging artcraft.

- Soft Furniture Cutting Solutions

- Soft Furniture Laser Marking Applications

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: