-

Industry Trends/Customer Challenges

Industry Trends/Customer ChallengesHigh Hiring Costs: Factory is hard to employ the skillful workers, and young generation don't want to working in factory, cause labor salary keep increasing.

High Raw Material: Because of the high cost of leather raw material itself, how to try our best to reduce material consumption.

Mold Storage and Management: More and more small quanity and variety orders, the trend of intelligent manufacturing and management for lots of molds and space for tooling.

Marketing: The market everywhere is looking for the equipments can save labor and maximize productivity at the same time. The solutions we are contemplating is whether they can maintain competitiveness through automation equipment.

-

Advantages of GBOS Solutions

Advantages of GBOS SolutionsMold-saving: No need the molds, saved the cost/time/space for huge quantity of tooling.

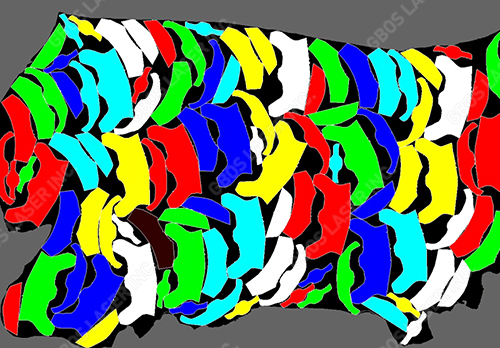

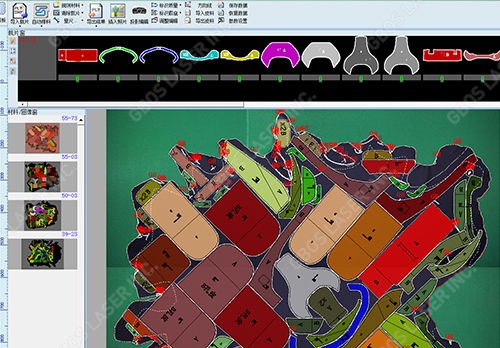

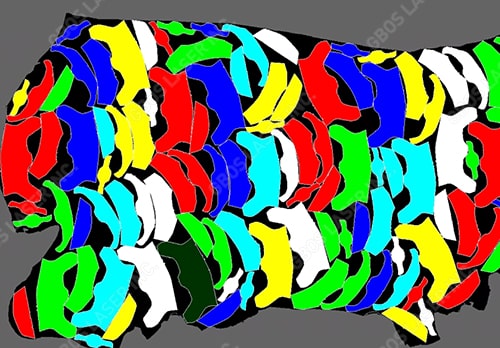

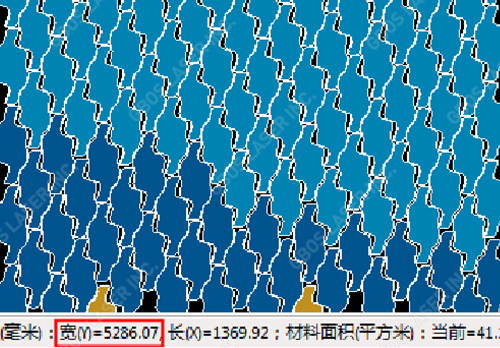

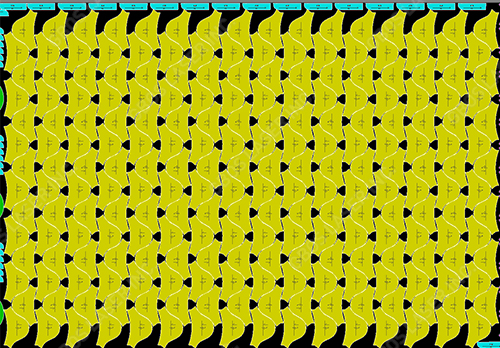

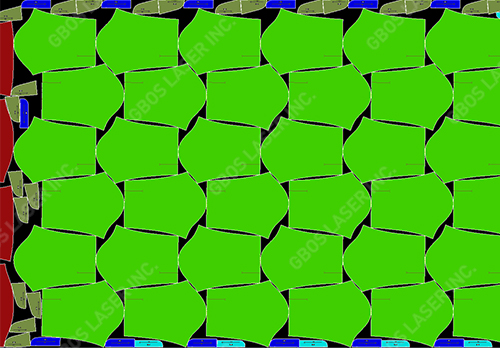

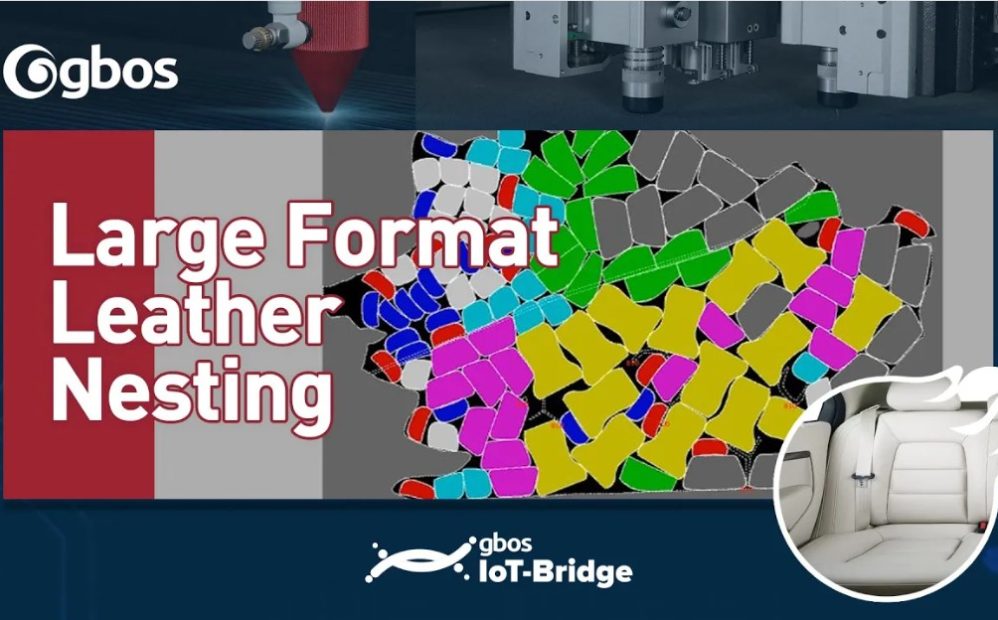

High Material Utilisation: By integrating self-developed multiple algorithms, the utilization rate of leather materials can reach 85% and above.

Synthetic Leather Nesting: Covering various nesting algorithms such as extra-long, paired-double, etc.

Meet Various Orders: Large, variety and medium/small quantity order acceptable, enlarge enterprises profits.

All in One: Various processes can be finished at one time (cutting, punching, marking, engraving, lining), can easily cut different shapes and sizes of the pieces. And precision can be up to 0.1mm, high efficiency, ensure the standard products quality.

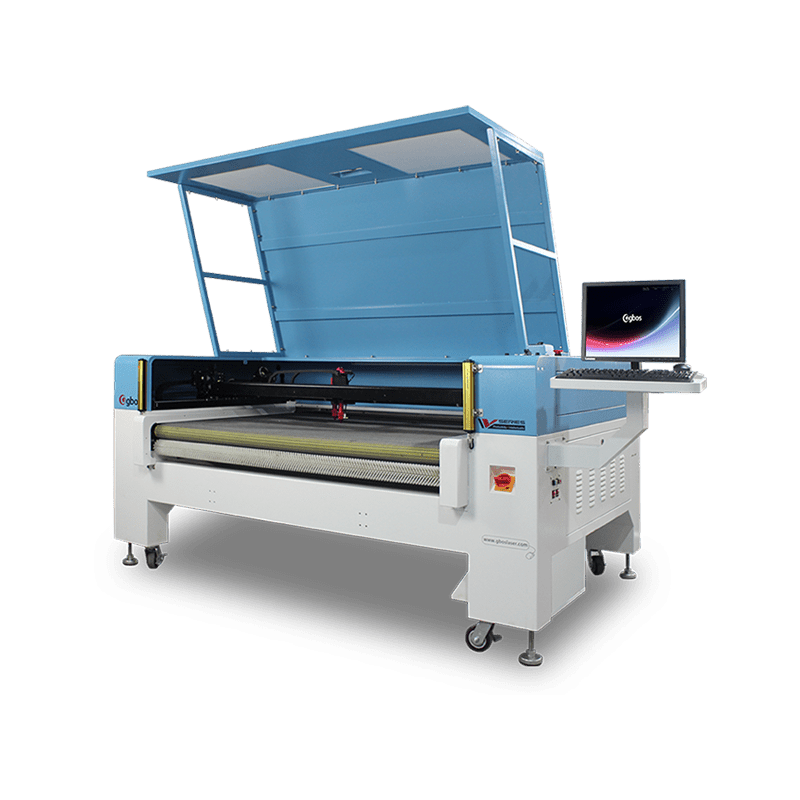

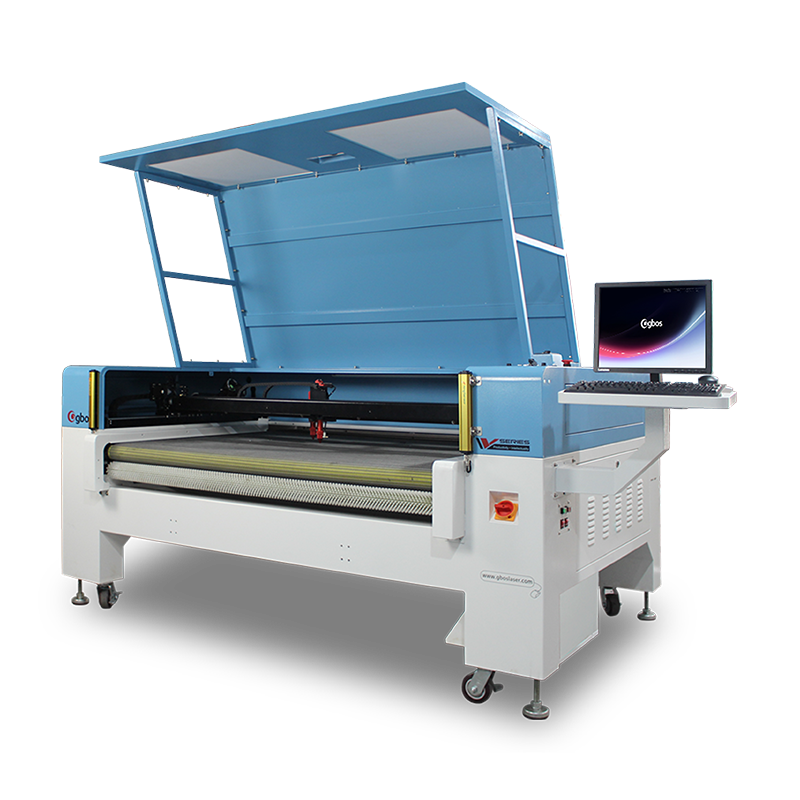

Simplify the Progress: Equipped with automatic feeding system, continuous feeding cutting, leather in rolls can be directly put on the working table, and start processing, cutting/punching at one time, saving a lot of time, efficiency improves a lot.

Digitalization: Daily production, production target, current progress, estimate time, cutting quantity, all can be real-time monitored, feedback in system, orders manufacture planning will be more orderly and reasonable.

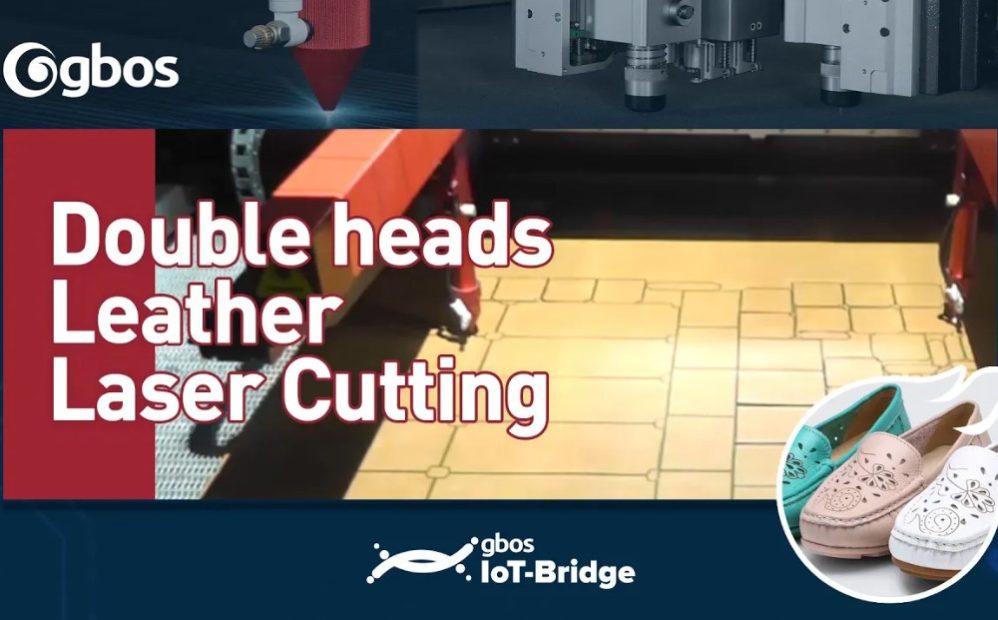

- Leather Laser Cutting Solution

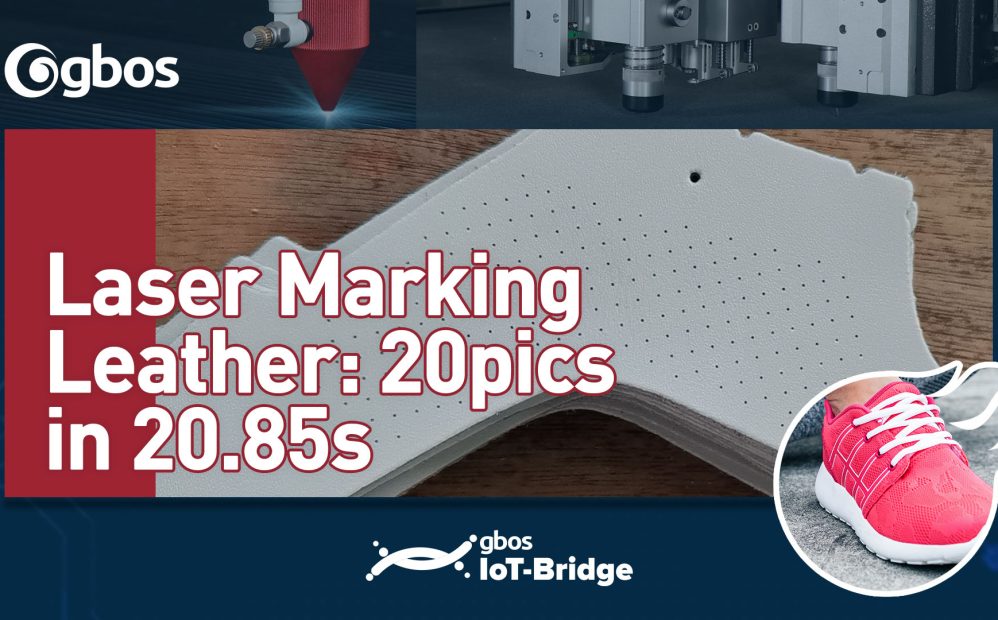

- CO2 Laser Makring/Engraving Leather Solution

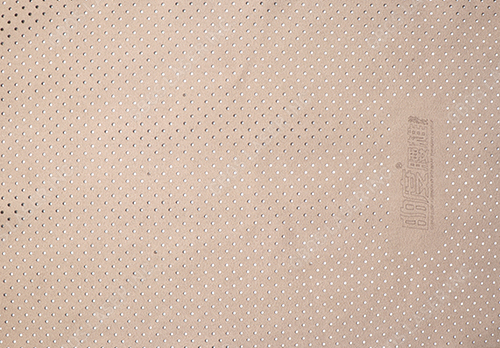

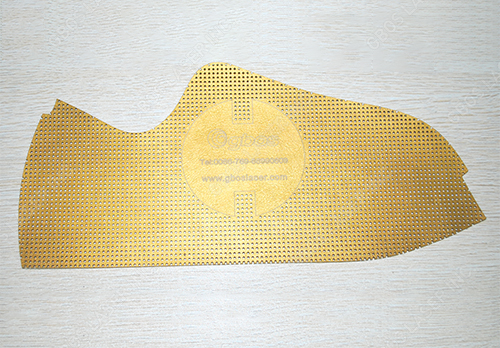

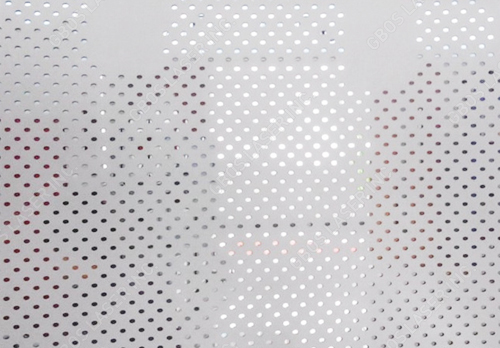

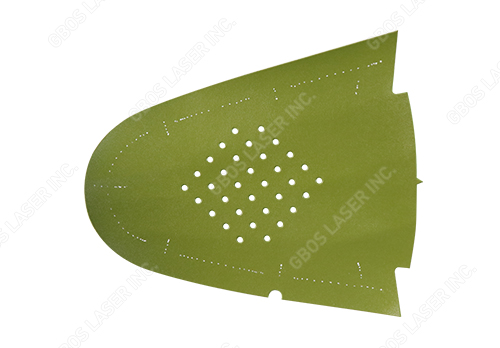

- Laser Perfoarting Leather Holes Solution

- UV Laser Marking Leather Solution

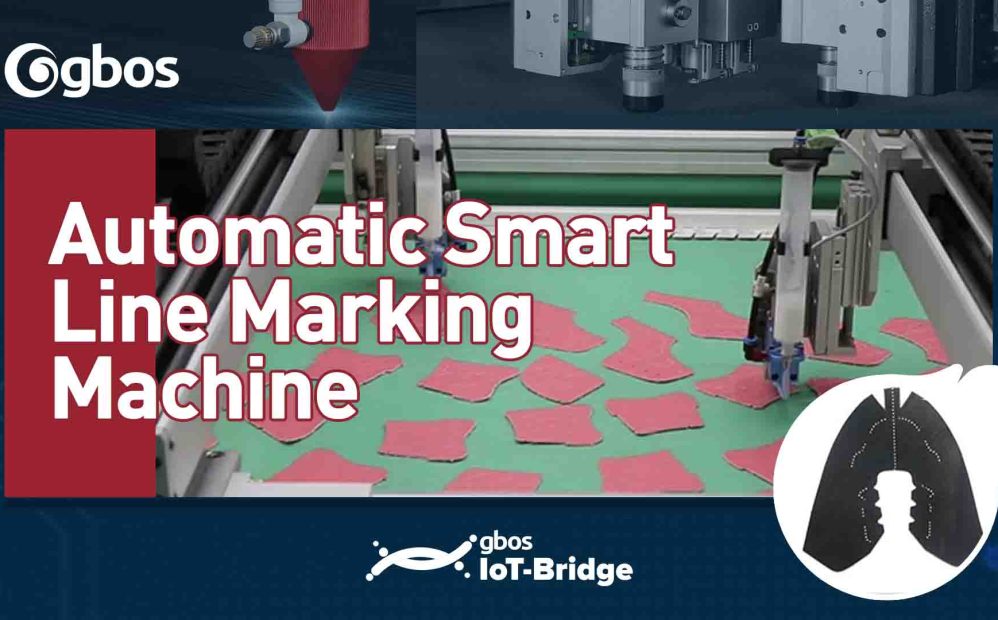

- Leather Auto Line Marking Solution

- Leather Nesting for Irregular Material

- Leather Nesting for Regular Material

-

Leather Jacket Laser Marking

Leather Jacket Laser Marking -

Leather Jacket Laser Engraving Perforating

Leather Jacket Laser Engraving Perforating -

Car Seat Leather Laser Engraving

Car Seat Leather Laser Engraving -

Leather Headrest Laser Engraving

Leather Headrest Laser Engraving -

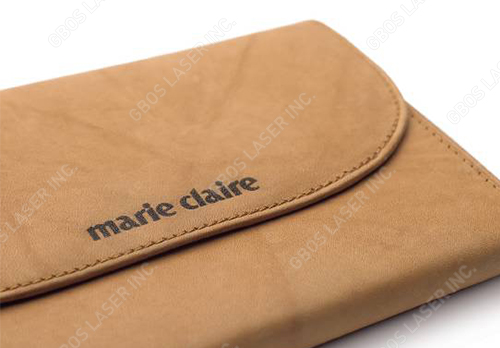

Leather Wallet Laser Engraving

Leather Wallet Laser Engraving -

Waist Pillow Laser Marking

Waist Pillow Laser Marking -

Leather Handbag Laser Marking Engraving

Leather Handbag Laser Marking Engraving -

Laser Engraving Cutting Leather Label

Laser Engraving Cutting Leather Label -

Laser Engraving Leather Wallet

Laser Engraving Leather Wallet -

Leather Bags Accessories Laser Cutting

Leather Bags Accessories Laser Cutting -

Leather Handbag Laser Marking

Leather Handbag Laser Marking -

Leather Laser Engraving Marking

Leather Laser Engraving Marking -

Laser Cutting Engraving Leather

Laser Cutting Engraving Leather -

Laser Engraving for Leather Satchel Bag

Laser Engraving for Leather Satchel Bag -

Leather Handbag Laser Cutting

Leather Handbag Laser Cutting -

Leather Handbag Laser Cutting

Leather Handbag Laser Cutting

-

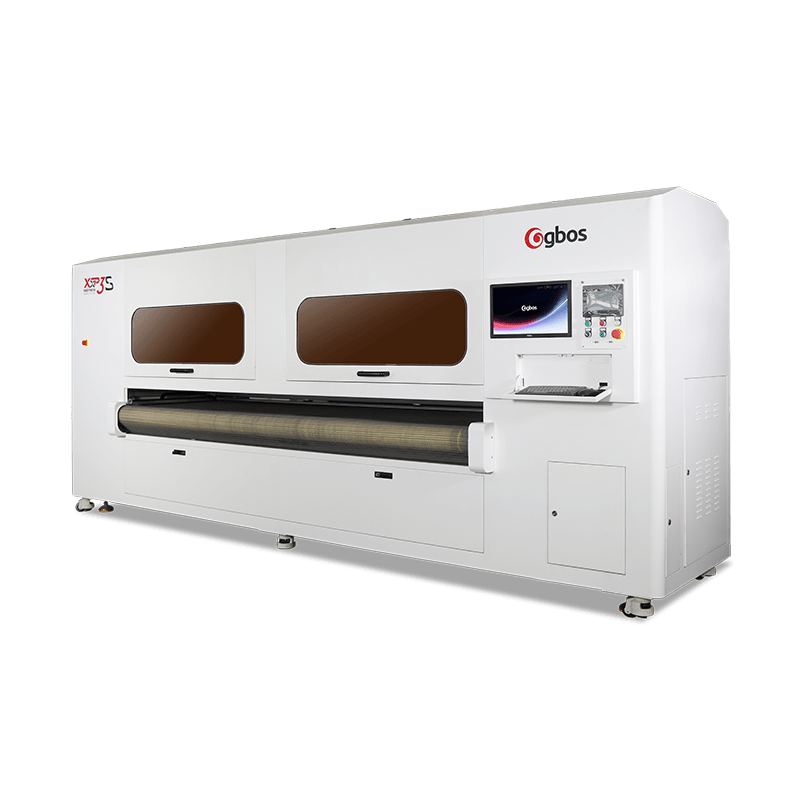

XXP3-250High Speed Galvo Birthday Greeting Card Wedding card Laser Engraving Cutting Marking MachineMore Details

XXP3-250High Speed Galvo Birthday Greeting Card Wedding card Laser Engraving Cutting Marking MachineMore Details -

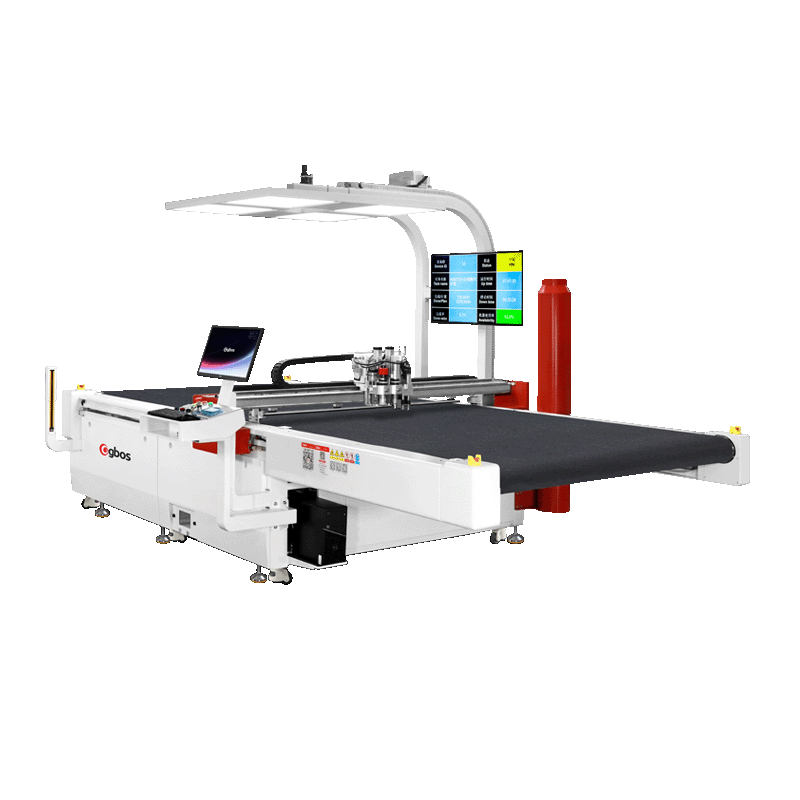

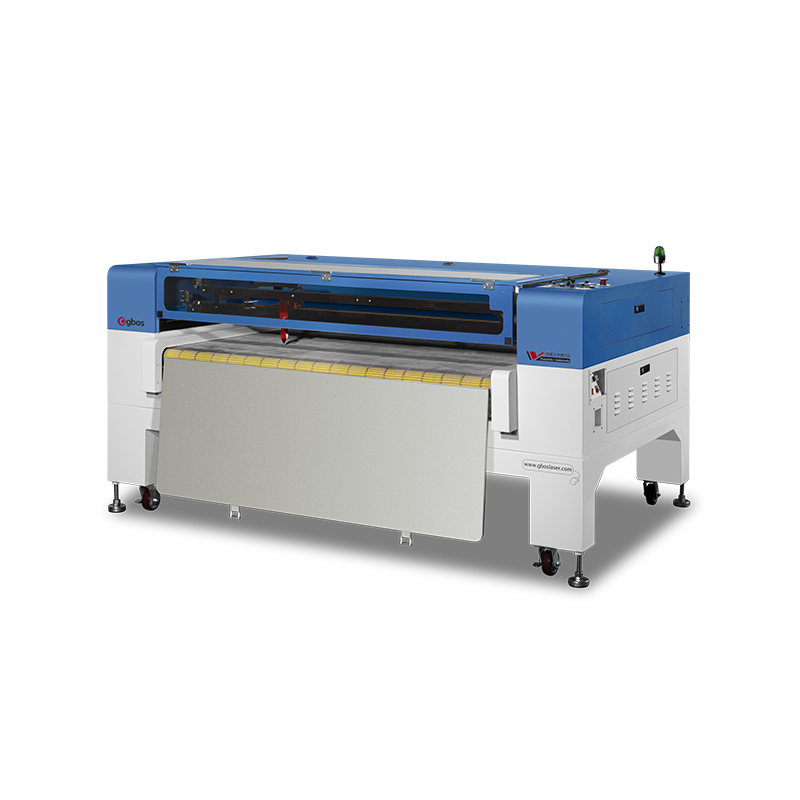

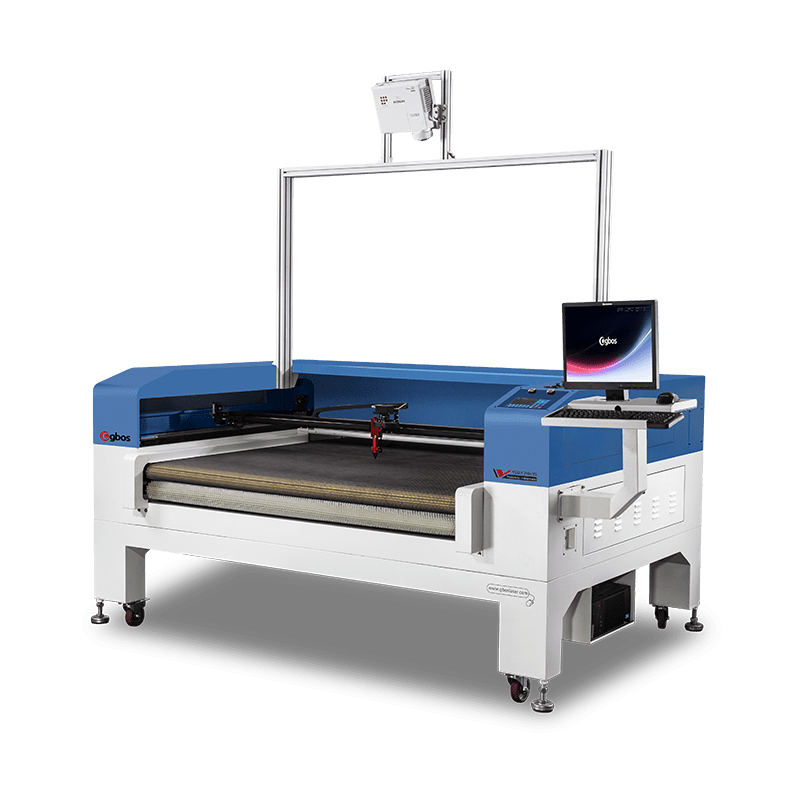

GH1610T-AT-CCDTwo-head Intelligent Auto Feeding Laser Cutting Machine With High-precision CameraMore Details

GH1610T-AT-CCDTwo-head Intelligent Auto Feeding Laser Cutting Machine With High-precision CameraMore Details -

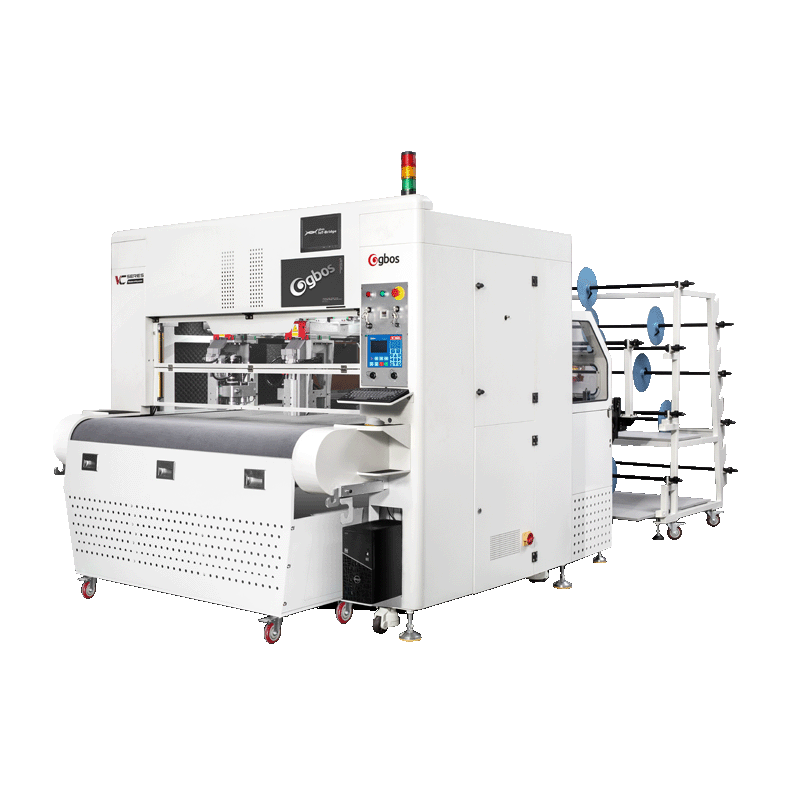

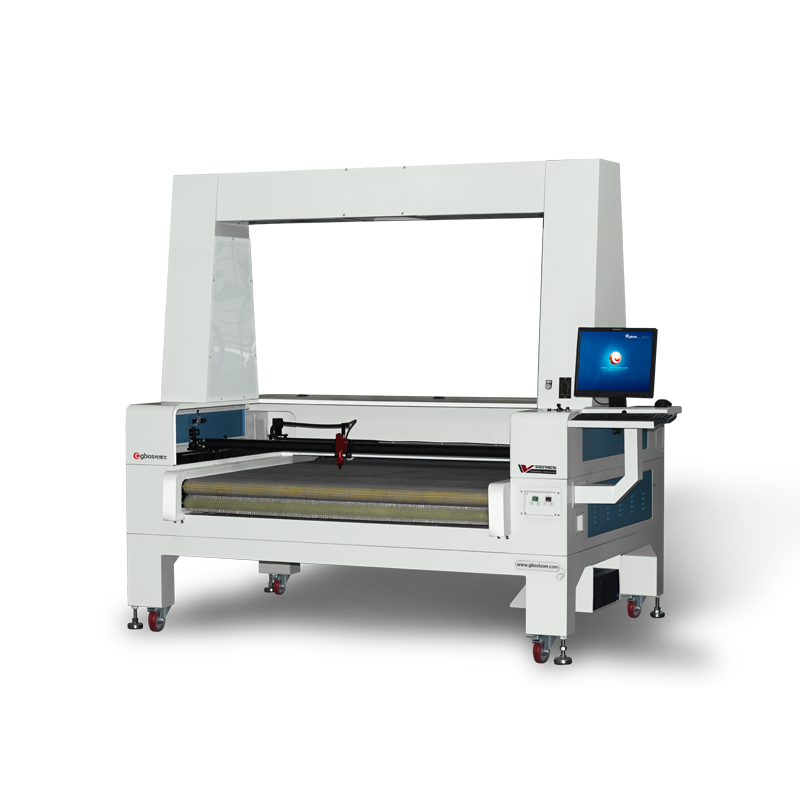

GH1812T-AT-HD-SCCDTwo heads Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

GH1812T-AT-HD-SCCDTwo heads Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details -

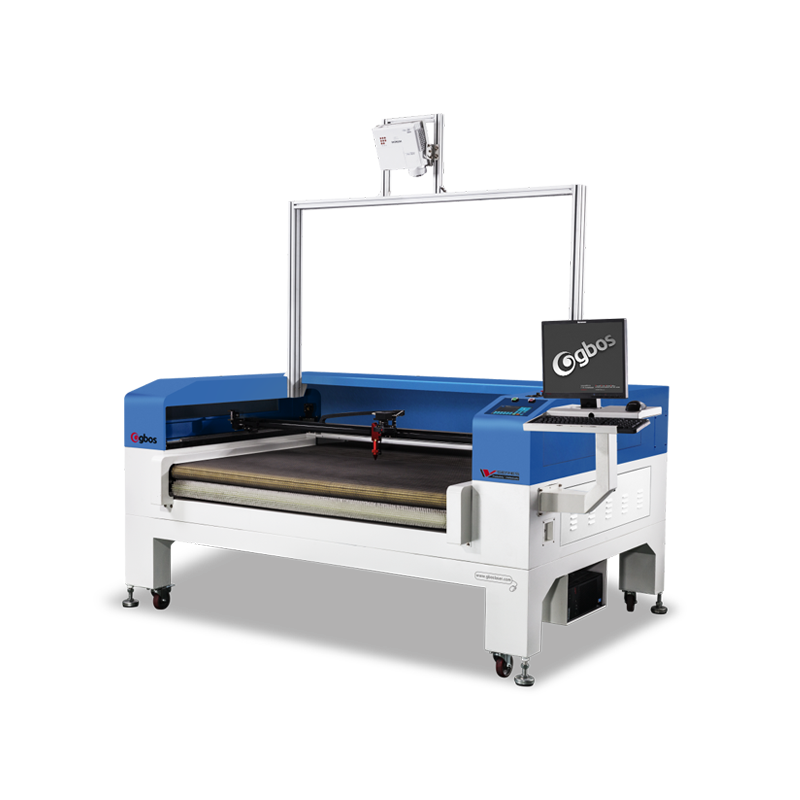

GH1812T-AT-SCCDTwo heads Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

GH1812T-AT-SCCDTwo heads Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details -

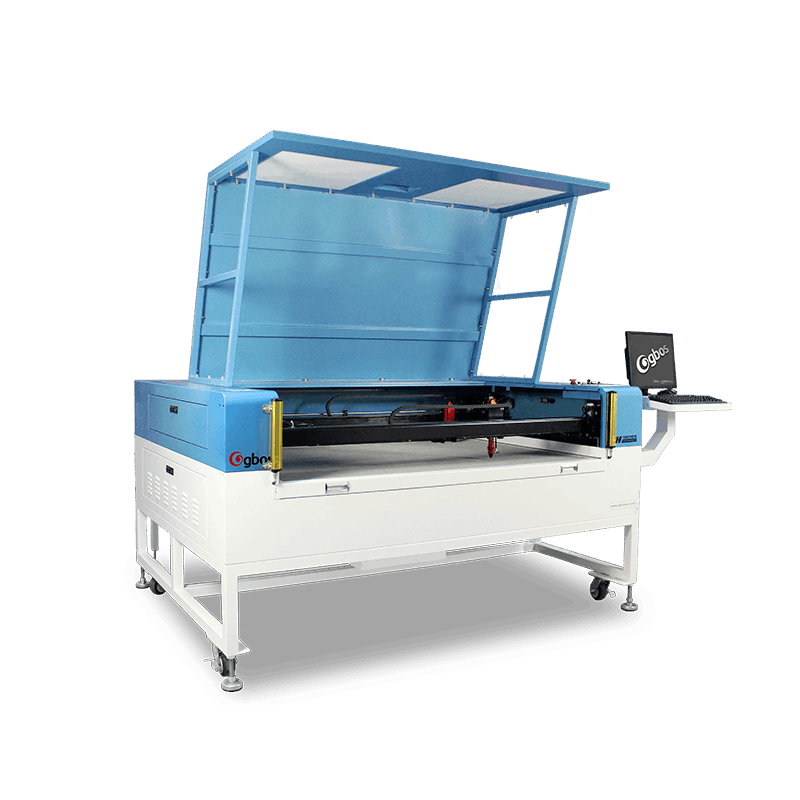

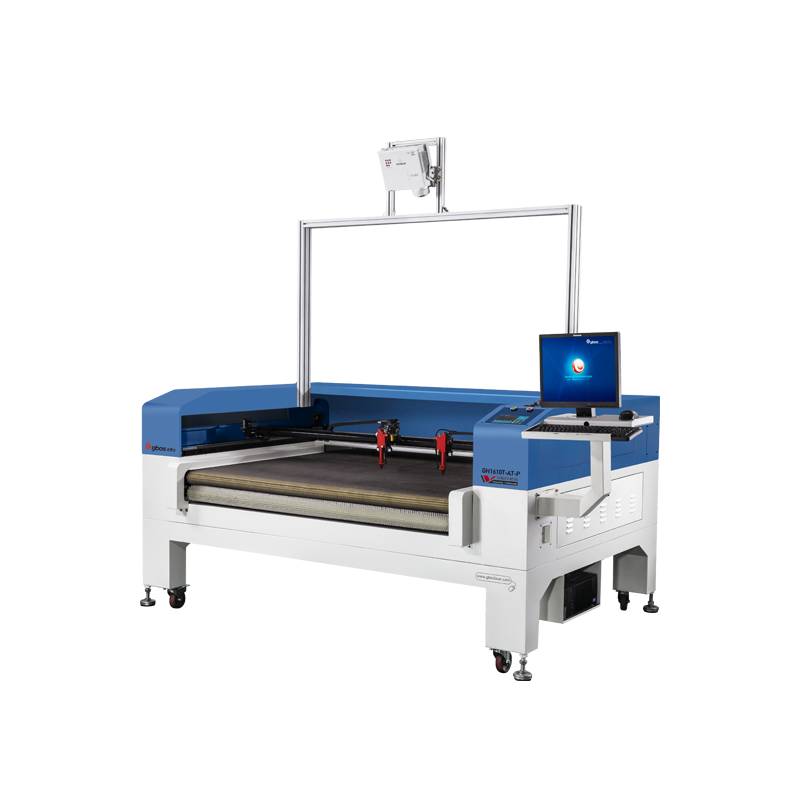

GH1812(TT)-AT-SCCDTwo Heads Asynchronous Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

GH1812(TT)-AT-SCCDTwo Heads Asynchronous Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

-

Mar 16,2024

![Small Batch& Customized–Leather Sofa [One-stop] Intelligent Nesting + Cutting Small Batch& Customized–Leather Sofa [One-stop] Intelligent Nesting + Cutting](https://www.gboslaser.com/wp-content/uploads/2024/03/2024031611520755fd2.jpg) “As the rigid demand for living space grows among the younger generation, the demand for furniture catering to small spaces, cost-effectiveness, and integrated design is increasing. This trend, coupled with increasingly stringent environmental standards set by the government, is pushing leather furniture manufacturers to transition towards digitization and green manufacturing, aiming for dual optimization of cost-effectiveness.” 01 Leather Nesting and Cutting: Manual vs. Automated Traditionally, crafting a standard leather sofa requires nesting and cutting different sizes and qualities of leather for various parts of the sofa. During this process, craftsmen face challenges such as material displacement and wastage through manual nesting and cutting. This method not only lacks efficiency but also results in low material utilization. Additionally, it’s difficult to transfer such skills, leading to challenges in finding experienced craftsmen. In contrast, employing digital equipment for nesting centralizes data processing and swiftly provides multiple nesting schemes through cloud computing analysis, significantly reducing material wastage and achieving efficient cutting. This integrated solution of nesting and cutting saves considerable time, labor costs, and boosts leather utilization rates to 85% or higher. Moreover, the nesting equipment seamlessly connects with cutting equipment, achieving nesting + cutting in one step, saving...

“As the rigid demand for living space grows among the younger generation, the demand for furniture catering to small spaces, cost-effectiveness, and integrated design is increasing. This trend, coupled with increasingly stringent environmental standards set by the government, is pushing leather furniture manufacturers to transition towards digitization and green manufacturing, aiming for dual optimization of cost-effectiveness.” 01 Leather Nesting and Cutting: Manual vs. Automated Traditionally, crafting a standard leather sofa requires nesting and cutting different sizes and qualities of leather for various parts of the sofa. During this process, craftsmen face challenges such as material displacement and wastage through manual nesting and cutting. This method not only lacks efficiency but also results in low material utilization. Additionally, it’s difficult to transfer such skills, leading to challenges in finding experienced craftsmen. In contrast, employing digital equipment for nesting centralizes data processing and swiftly provides multiple nesting schemes through cloud computing analysis, significantly reducing material wastage and achieving efficient cutting. This integrated solution of nesting and cutting saves considerable time, labor costs, and boosts leather utilization rates to 85% or higher. Moreover, the nesting equipment seamlessly connects with cutting equipment, achieving nesting + cutting in one step, saving... -

Mar 30,2023

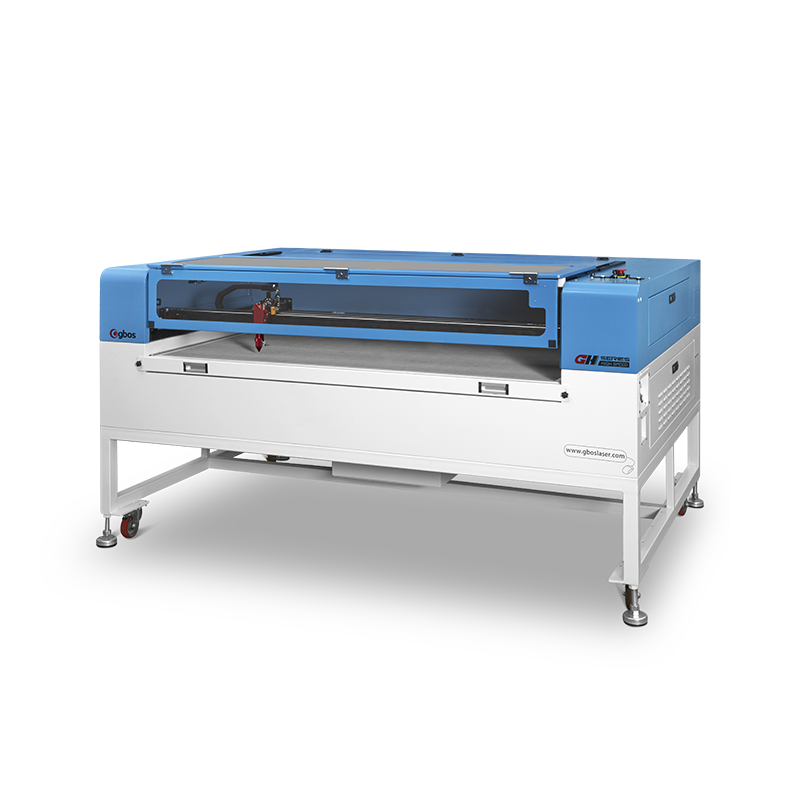

The leather and footwear industry around the world is witnessing a paradigm shift in the way products are manufactured using laser technology. As we can see, traditional leather cutting: Obviously, in the production of bags, shoes, suitcases, boots, handbags and all other types of footwear, leather cutting by craftsmanship, we can meet the following problems: 1) Have an influence on product consistency. 2) Staff instability. 3) It’s different to achieve complex graphics cutting. 4) No guarantee of product quality. Laser can solve all. What’s more, laser cutting/marking/engraving leather will create more contribution to traditional art-craft. Now-day, fashion is popular, and the personalization is the trend. How to create competitiveness for your enterprise? How to follow the popularity? —— By using laser engraving/cutting machine. Enterprise enjoy shorter delivery and quicker responsiveness for their customers in high demand design. In other words, small volume and large-variety orders can be completed in time! Products can enter the market more faster! Design more creativity and unique! More efficient cutting/engraving way! Here, high speed laser marking/cutting/engraving machine for personalized customization. XXP3.2-180 Some details: 1) Red light preview. 2) Large working area, maximum 600*600mm. (the processing area is adjustable) 3) Speed increased up 20%. 4) Compact structure ,easy operation. Click and know more...

The leather and footwear industry around the world is witnessing a paradigm shift in the way products are manufactured using laser technology. As we can see, traditional leather cutting: Obviously, in the production of bags, shoes, suitcases, boots, handbags and all other types of footwear, leather cutting by craftsmanship, we can meet the following problems: 1) Have an influence on product consistency. 2) Staff instability. 3) It’s different to achieve complex graphics cutting. 4) No guarantee of product quality. Laser can solve all. What’s more, laser cutting/marking/engraving leather will create more contribution to traditional art-craft. Now-day, fashion is popular, and the personalization is the trend. How to create competitiveness for your enterprise? How to follow the popularity? —— By using laser engraving/cutting machine. Enterprise enjoy shorter delivery and quicker responsiveness for their customers in high demand design. In other words, small volume and large-variety orders can be completed in time! Products can enter the market more faster! Design more creativity and unique! More efficient cutting/engraving way! Here, high speed laser marking/cutting/engraving machine for personalized customization. XXP3.2-180 Some details: 1) Red light preview. 2) Large working area, maximum 600*600mm. (the processing area is adjustable) 3) Speed increased up 20%. 4) Compact structure ,easy operation. Click and know more... -

Oct 30,2020

Judging from the recent leather garment accessories trends, many designers like to design specially elements in all differnt shoe uppers. It strengthens its breathability, and will more attractive. Especially in leather shoes, there are many different holes, big or small, regular or irregular, easy or difficult. You will say, making such a shoe need too much time, but now I tell you laser technology can help you up your speed and solve all problem~ Laser technology help you: 1) No materials, cutting thickness and pattern size limited. 2) No need making modules. 3) No need reworking again and again. And also laser can achieve touch-free process. This means there will no harm to leather or fabric when processing. And computer control system, will not have materials wasting. What’s more, not only used in shoe, but also in bags, even in greeting cards, paper, wood, silicone, etc. You can see some samples and application scene now~ Let laser help you solve all challenges~

Judging from the recent leather garment accessories trends, many designers like to design specially elements in all differnt shoe uppers. It strengthens its breathability, and will more attractive. Especially in leather shoes, there are many different holes, big or small, regular or irregular, easy or difficult. You will say, making such a shoe need too much time, but now I tell you laser technology can help you up your speed and solve all problem~ Laser technology help you: 1) No materials, cutting thickness and pattern size limited. 2) No need making modules. 3) No need reworking again and again. And also laser can achieve touch-free process. This means there will no harm to leather or fabric when processing. And computer control system, will not have materials wasting. What’s more, not only used in shoe, but also in bags, even in greeting cards, paper, wood, silicone, etc. You can see some samples and application scene now~ Let laser help you solve all challenges~

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: