-

Industry Trends/Customer Challenges

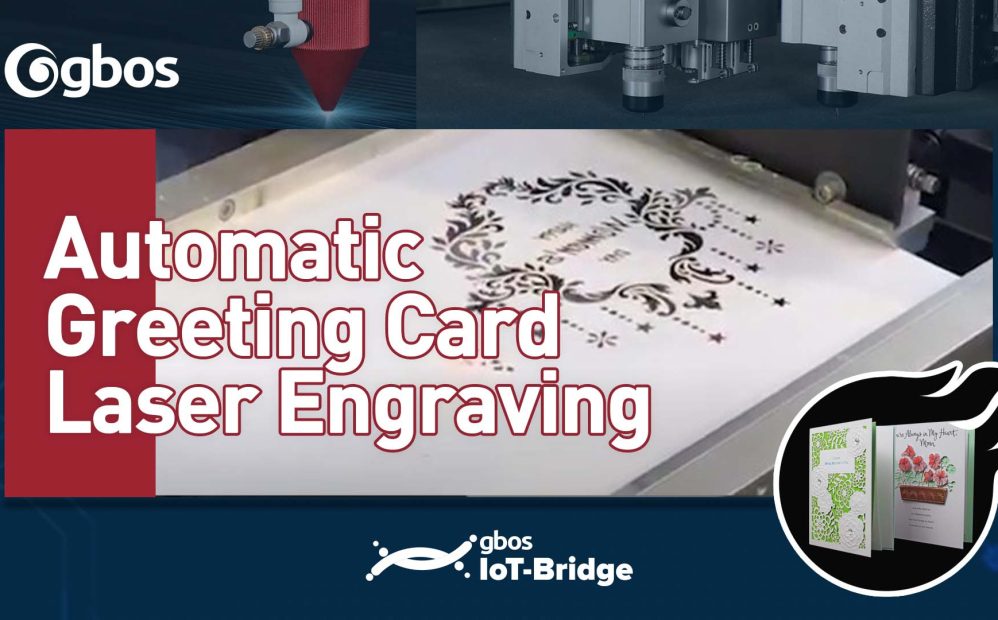

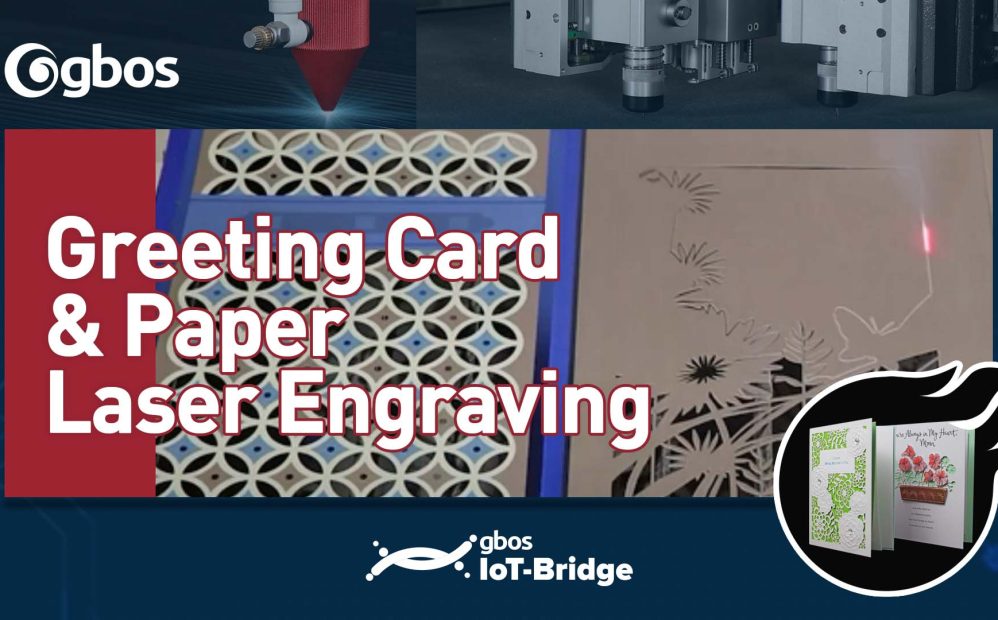

Industry Trends/Customer ChallengesThe traditional greeting card has a single form, takes a long time to process, consumes a lot of materials, and is not environmentally friendly. However, the market has higher requirements for the greeting card industry, such as personalized customization, automated production capacity requirements, environmental protection, and so on.

-

Advantages of GBOS Solutions

Advantages of GBOS SolutionsDurability and Environmental Friendliness: Laser markings typically exhibit increased durability, without the need for inks or chemical substances. This aligns with contemporary societal aspirations for environmentally friendly products, contributing to a sustainable approach in greeting card production.

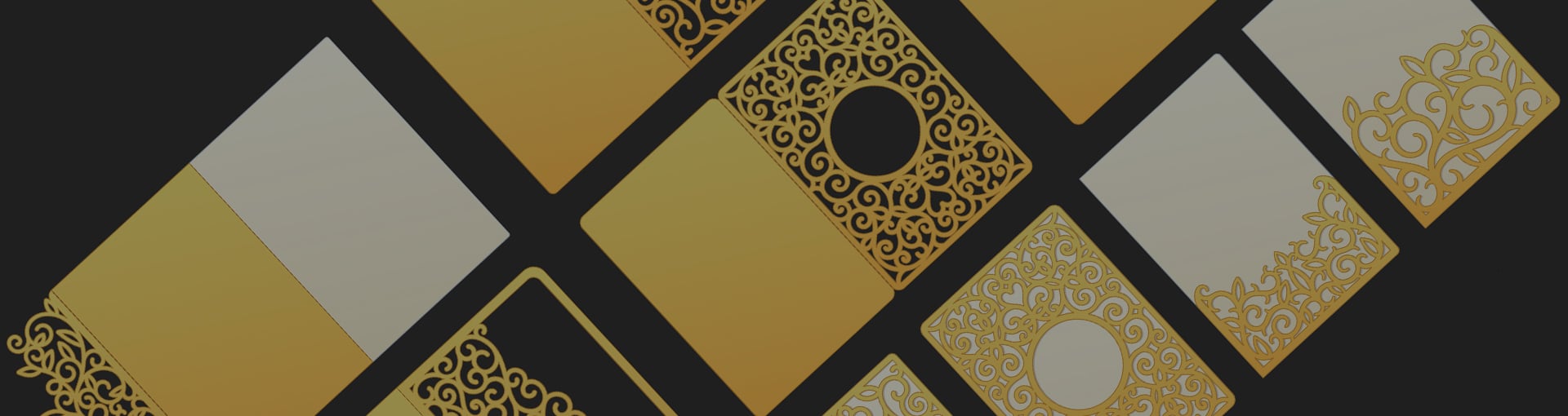

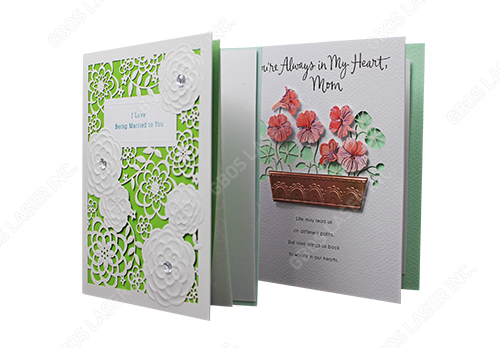

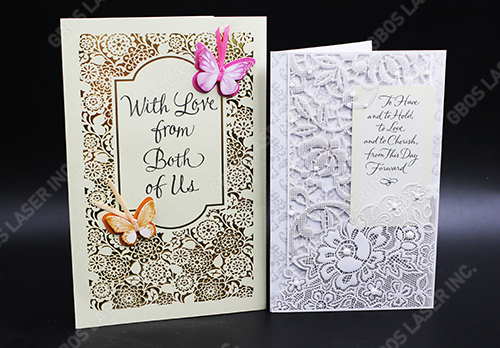

Customization and Personalization: In today's greeting card market, the emphasis on personalized products is profound. Laser marking technology grants creators greater flexibility, enabling the customization of unique designs, text, or patterns tailored to different occasions or individual preferences.

Exquisite Detail and High Accuracy: Laser marking technology showcases remarkable precision in crafting intricate details and achieving highly accurate text and patterns, imparting a professional and attention-grabbing appearance to greeting cards.

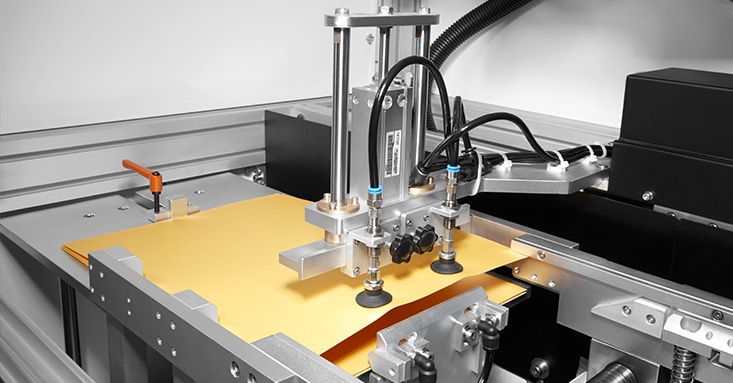

Fully automatic cutting, saving labor cost, can switch between full cutting, kiss (half) cutting, perforating, engraving, marking, no need ink, more environmentally friendly.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: