-

Industry Trends/Customer Challenges

Industry Trends/Customer ChallengesTraditional: Garment accessories cutting with complicated workflow, high costs, long delivery time and edge loose.

Customization and Rapid Delivery: Increasing consumer demand for customization and quick delivery.

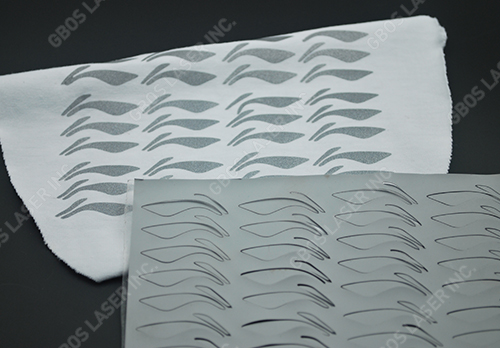

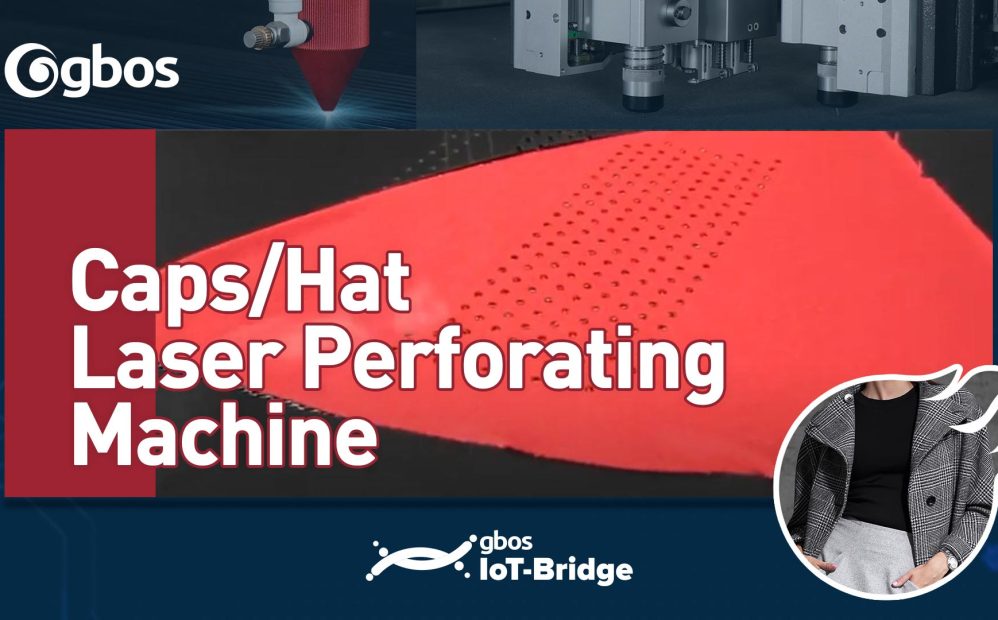

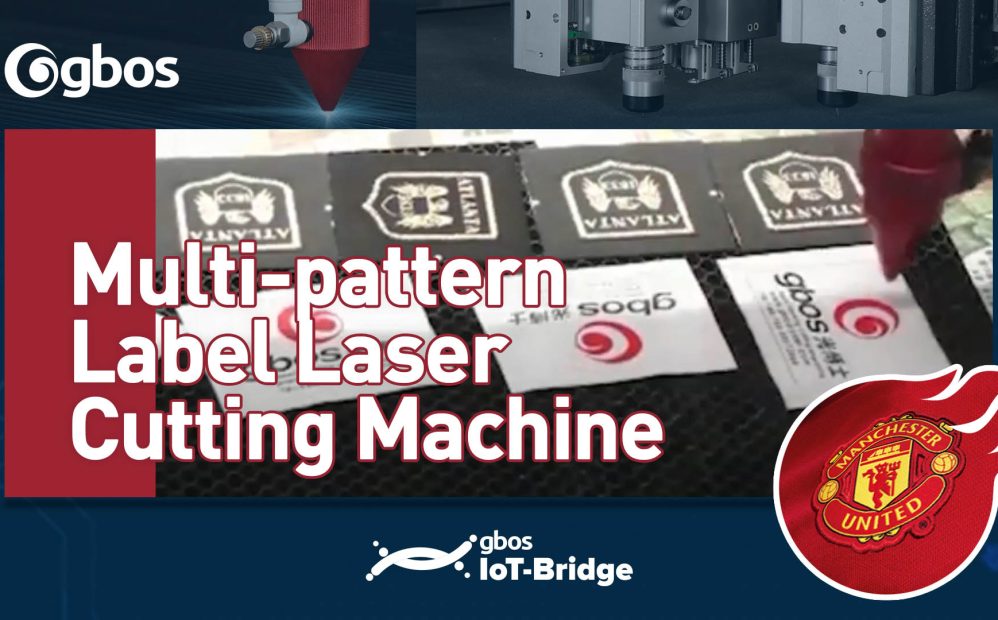

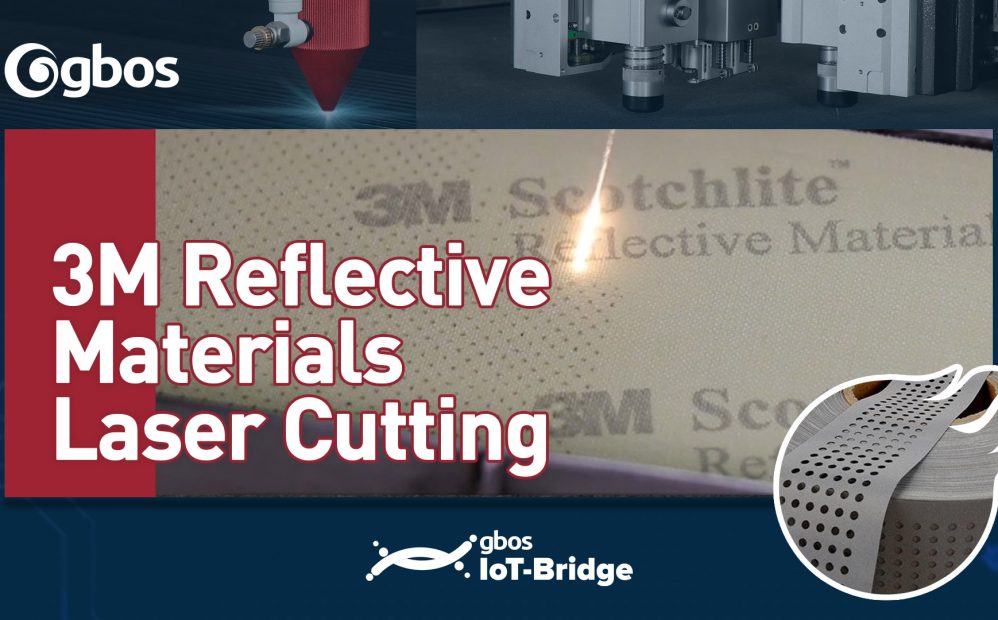

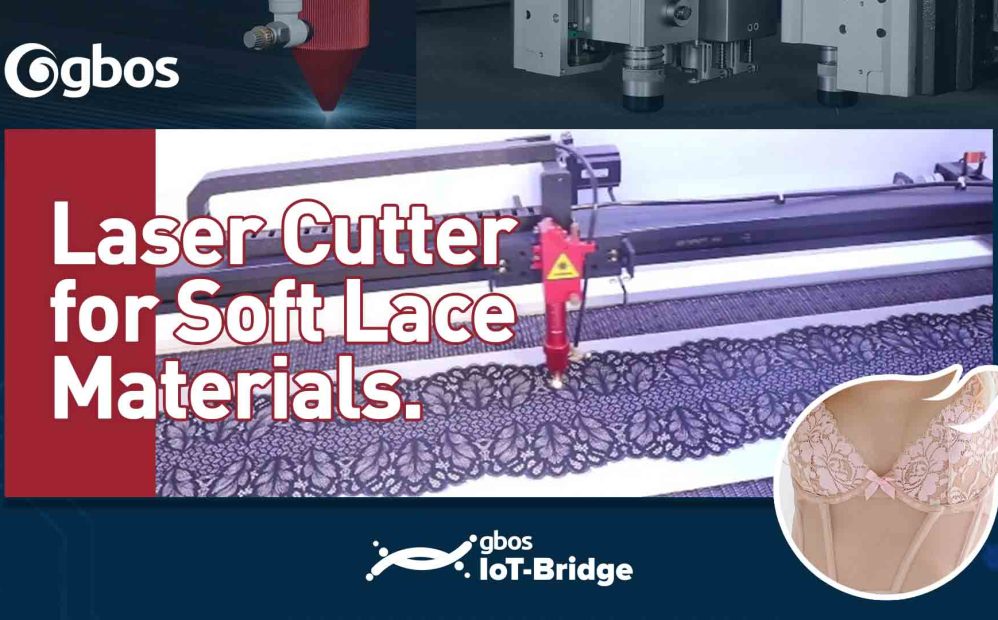

Complex Materials: Garment accessories typically involve multiple materials such as labels, hats, and gloves, each with different characteristics, adding complexity to the cutting process.

-

Advantages of GBOS Solutions

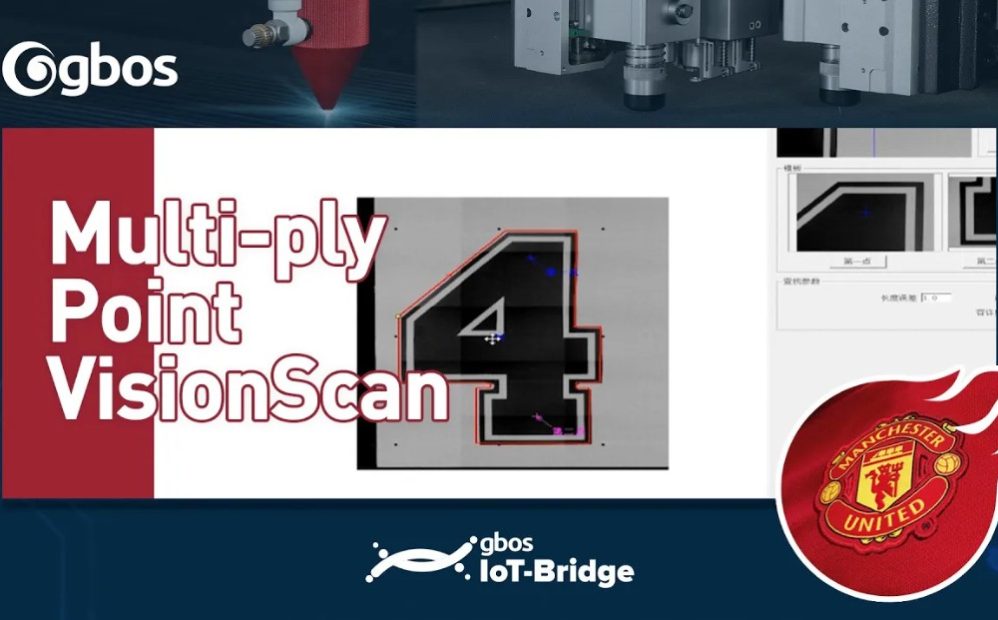

Advantages of GBOS SolutionsAI CCD VisionScan: Any angle, multi-point, multi-materials, multi-pattern concurrent positioning and cutting, automatically identify defect.

High Precision: With GBOS's self-developed AI CCD VisionScan tech, enabling accurate cutting of various complex accessory shapes and ensuring products meet the highest quality standards.

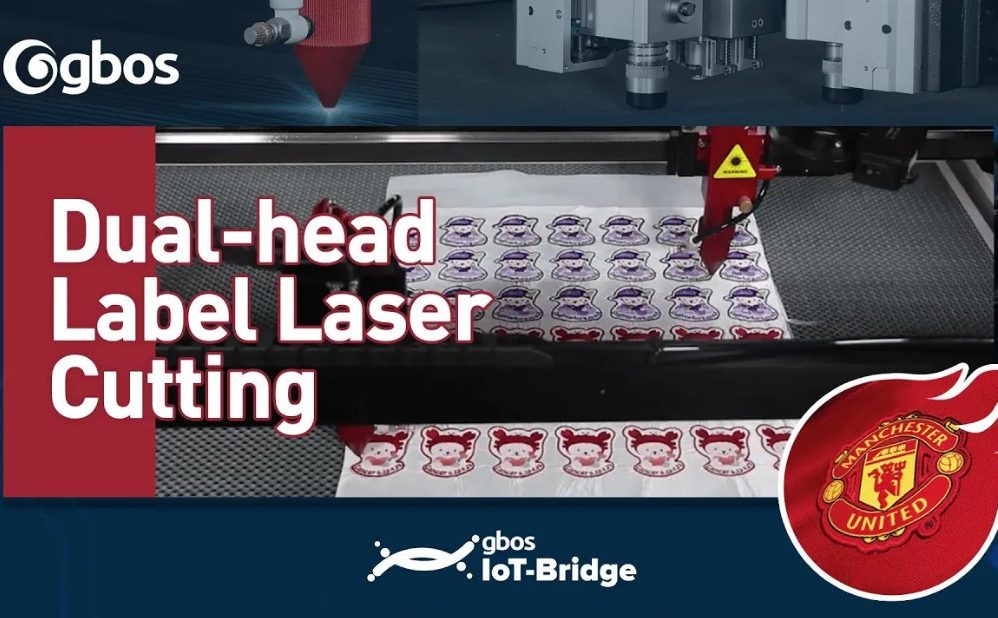

Fully Automated: 2 Times faster cutting speed; Half labor required; One person operate 3~5 sets of machine at the same time.

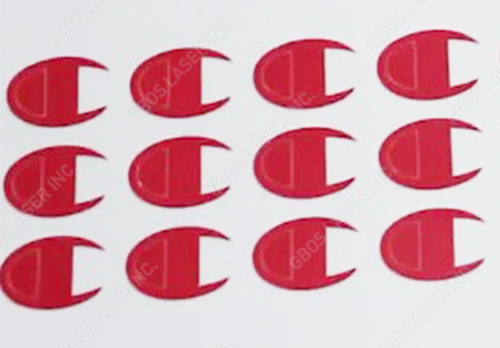

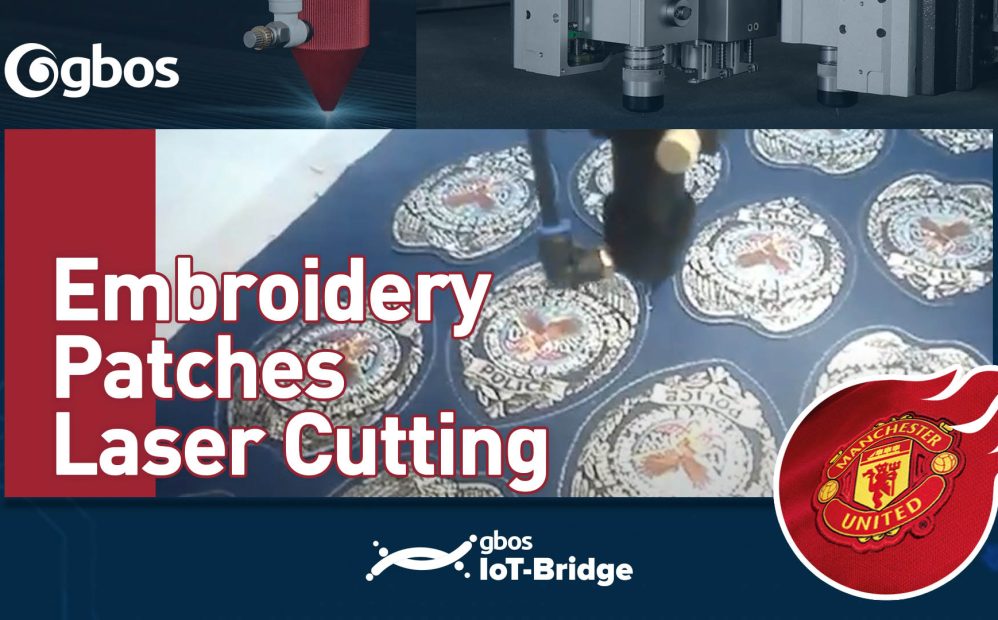

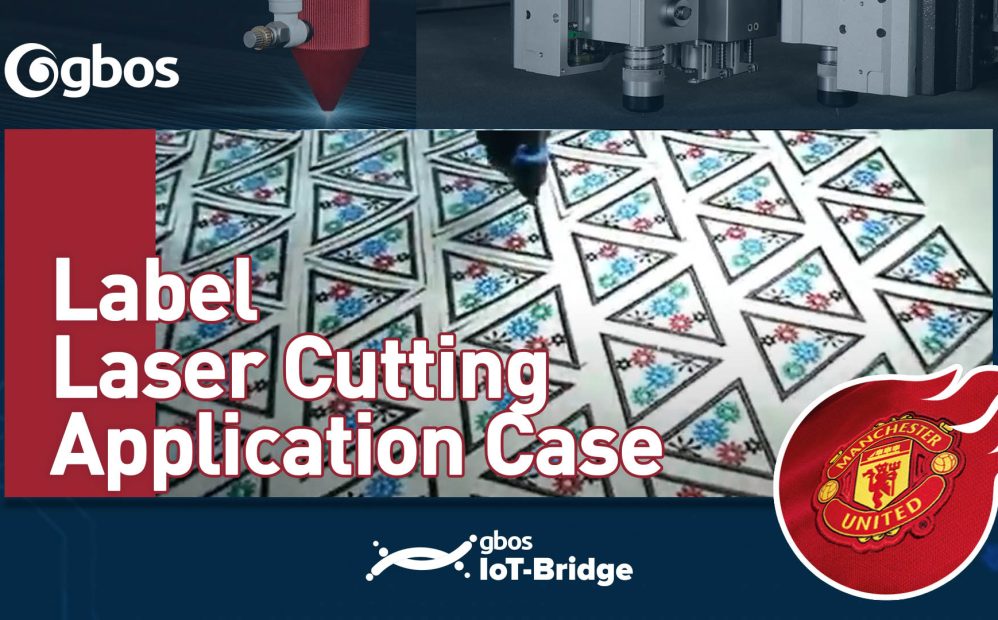

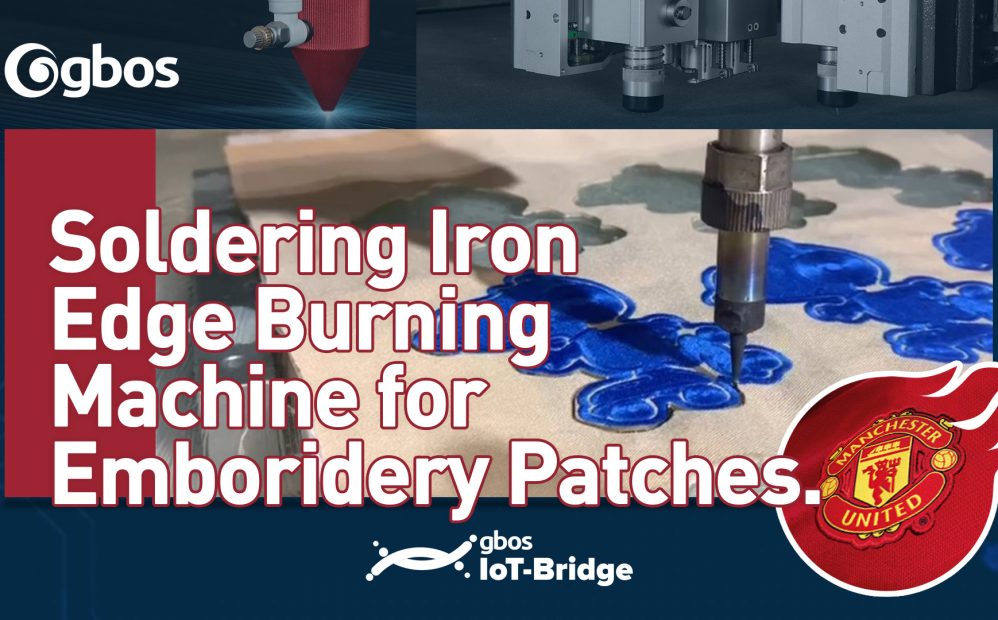

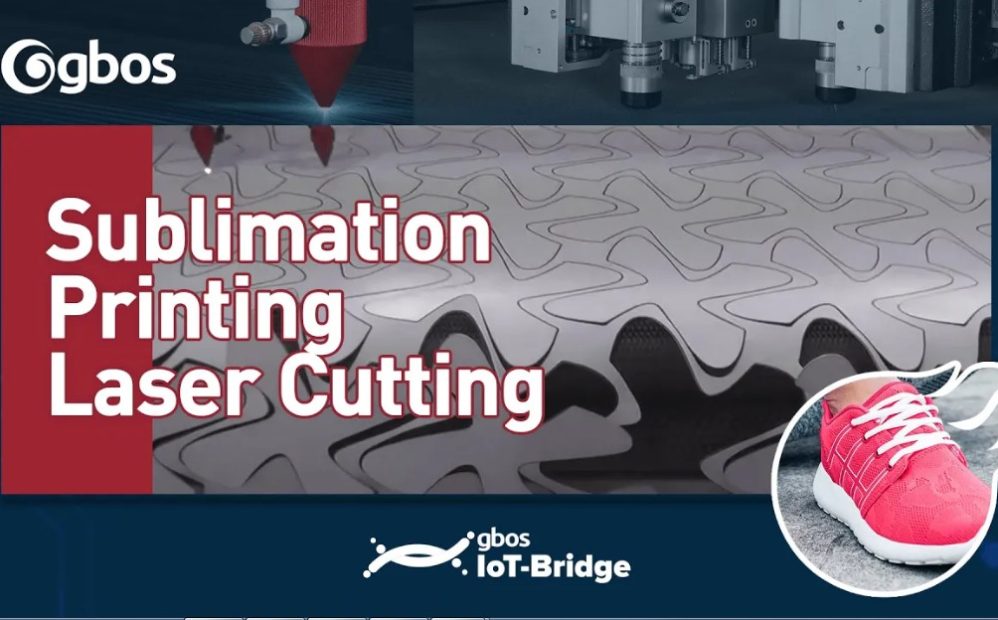

- Embroidery Patches Laser Cutting Solution

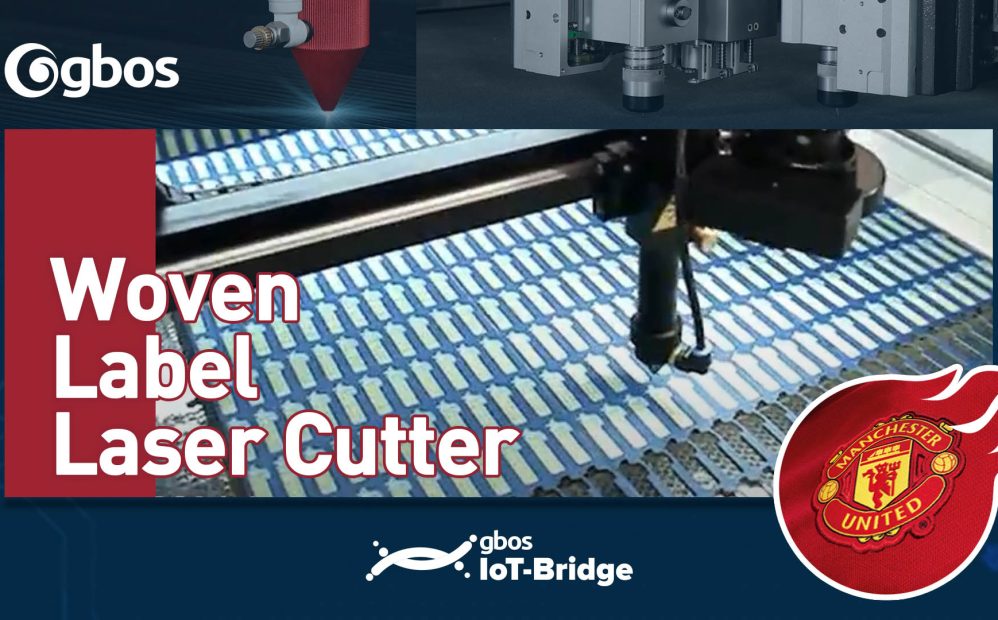

- Woven Label (Ribbon) Laser Cutting Solution

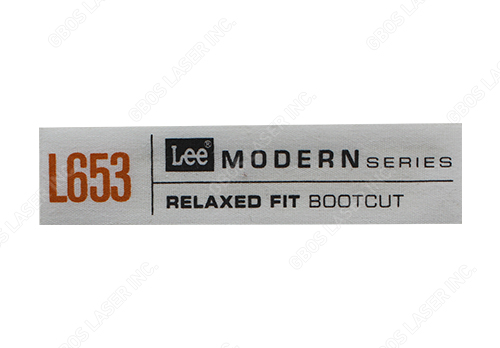

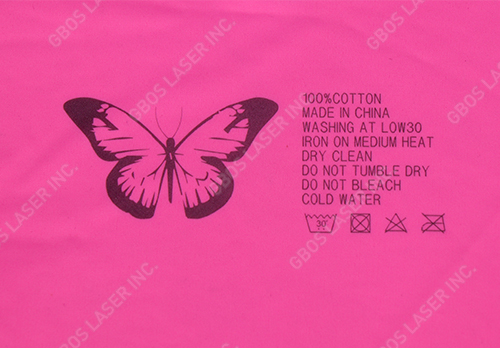

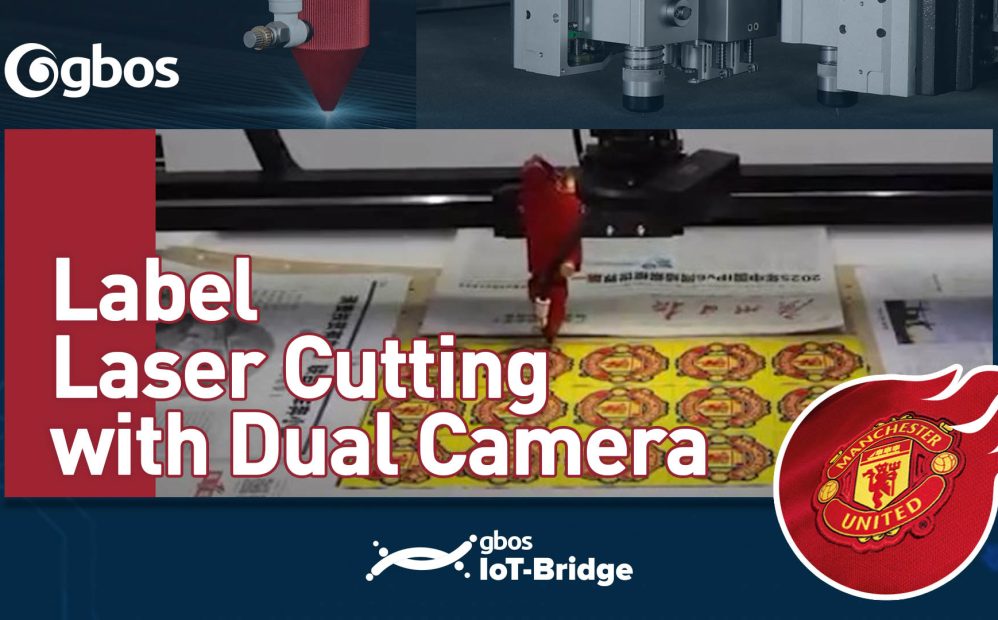

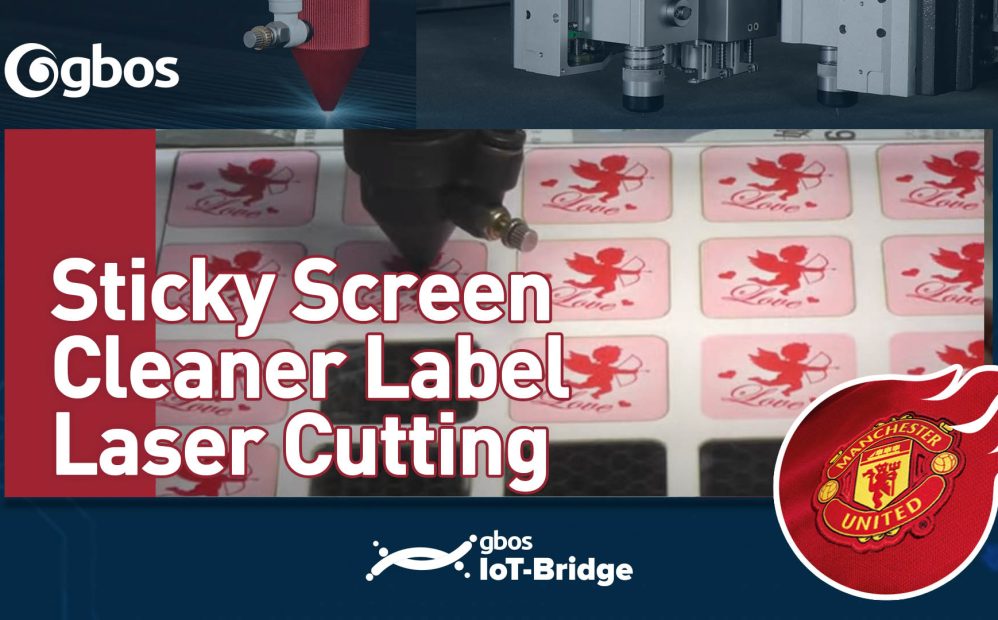

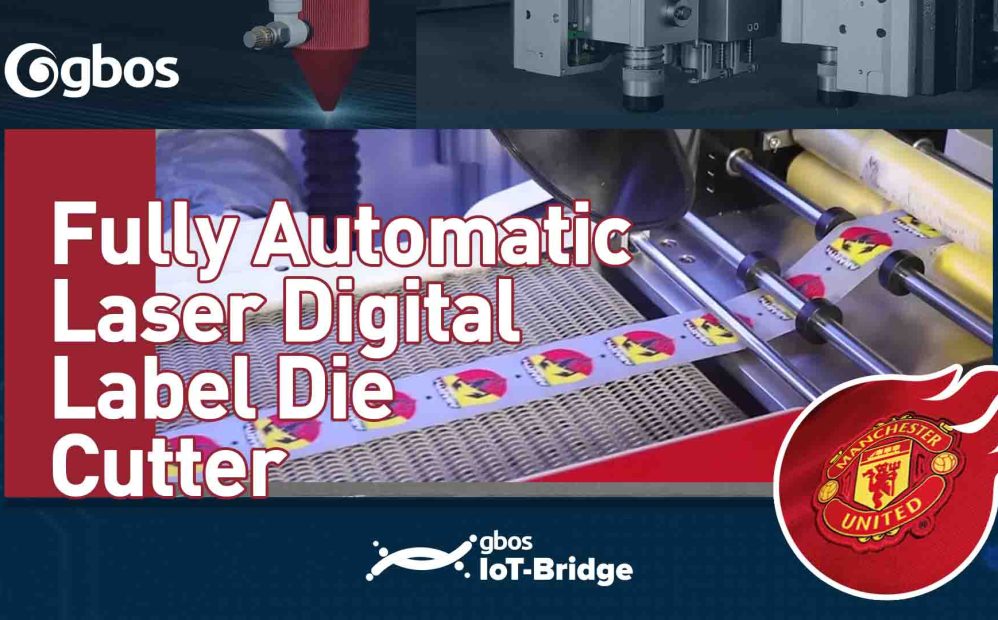

- Printing Label Laser Cutting Solution

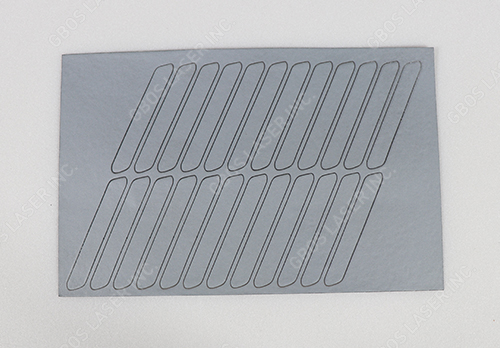

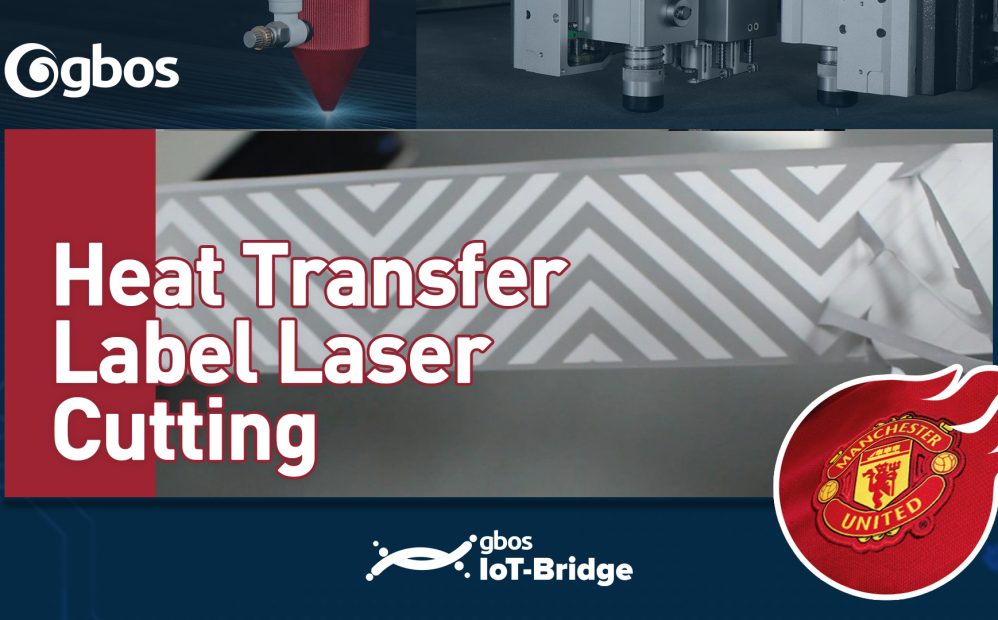

- Heat Transfer Viny Laser Cutting Solution

- Leather Label Laser Cutting and Engraving Solution

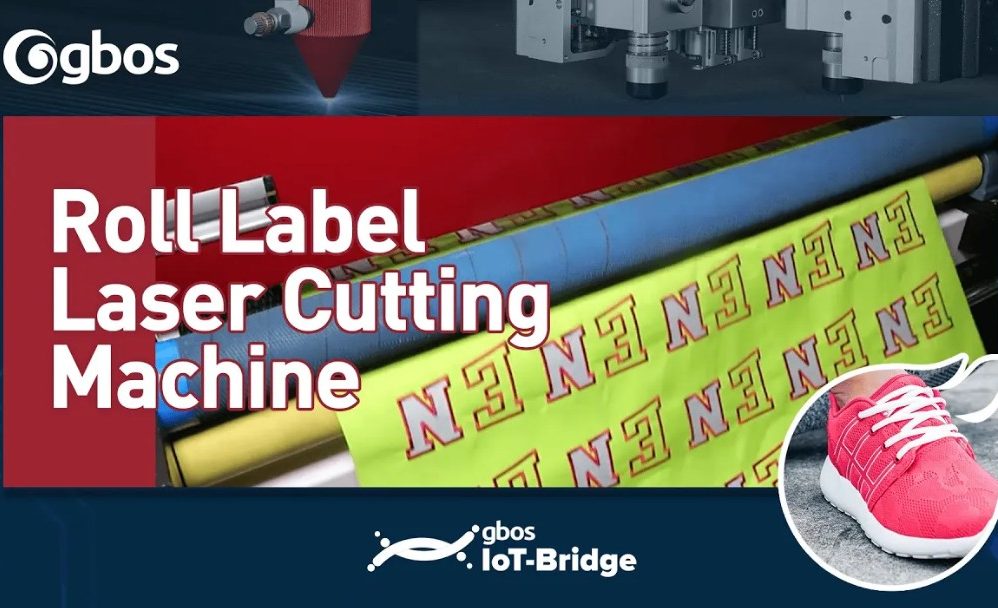

- Label and Tape Laser Solution

- Senseless Care Label UV Laser Marking Solution

- Cloth Tags Laser Cutting Solution

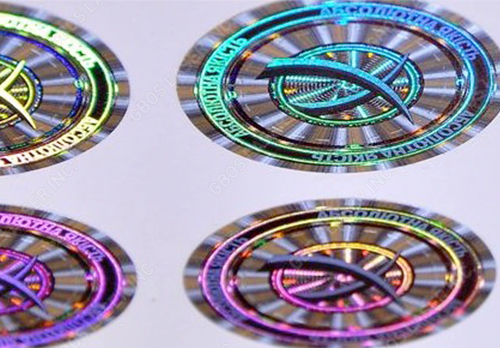

- Anti-counterfeit Label Laser Cutting

-

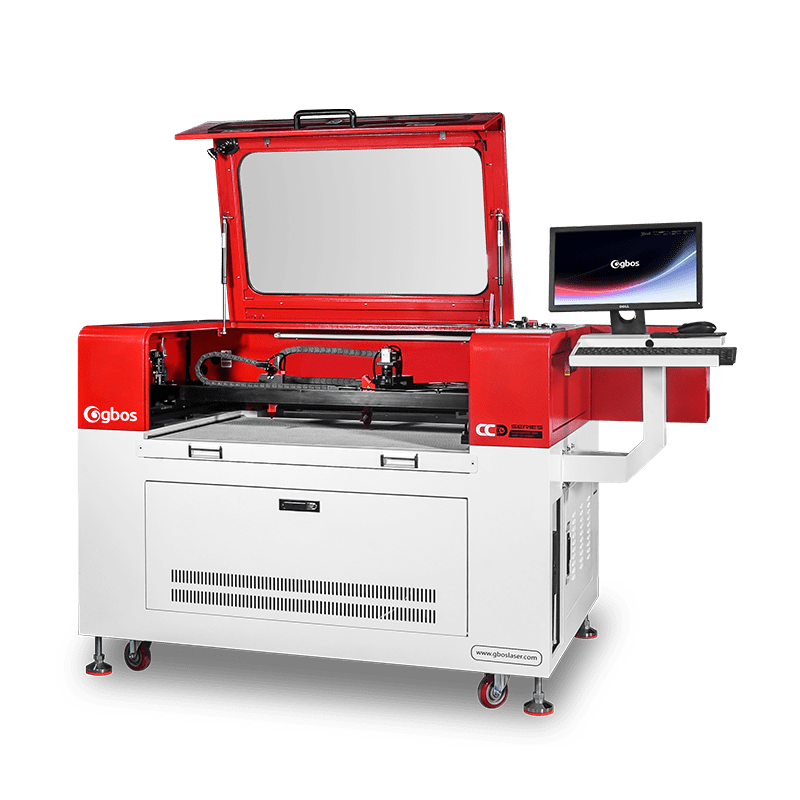

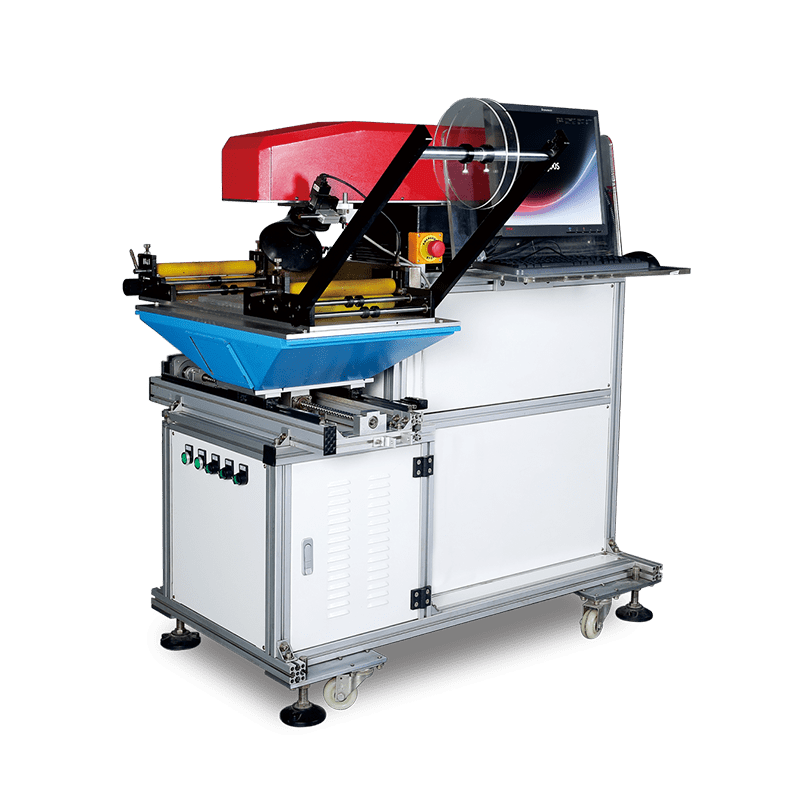

GN1081SCCD/5.0Dual AI Camera Laser Cutting Machine for Woven Printing Embroidery LableMore Details

GN1081SCCD/5.0Dual AI Camera Laser Cutting Machine for Woven Printing Embroidery LableMore Details -

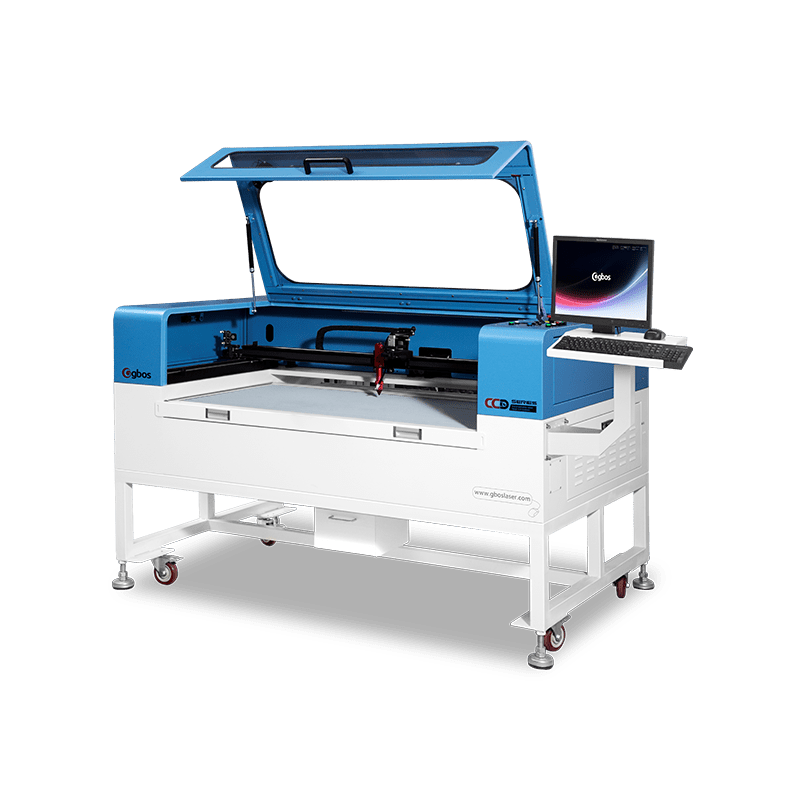

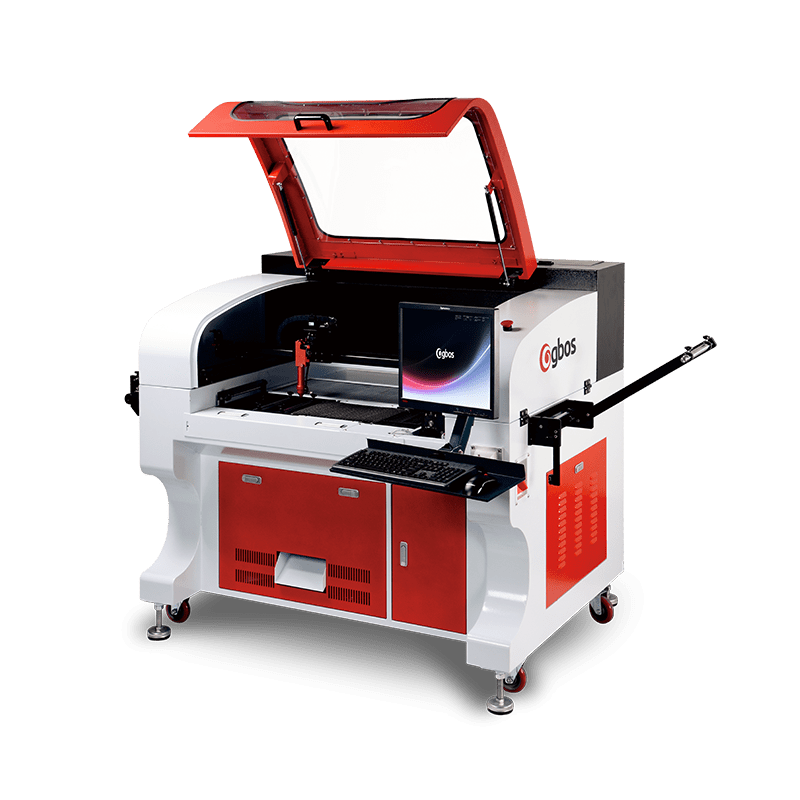

GH1610T-AT-CCDTwo-head Intelligent Auto Feeding Laser Cutting Machine With High-precision CameraMore Details

GH1610T-AT-CCDTwo-head Intelligent Auto Feeding Laser Cutting Machine With High-precision CameraMore Details -

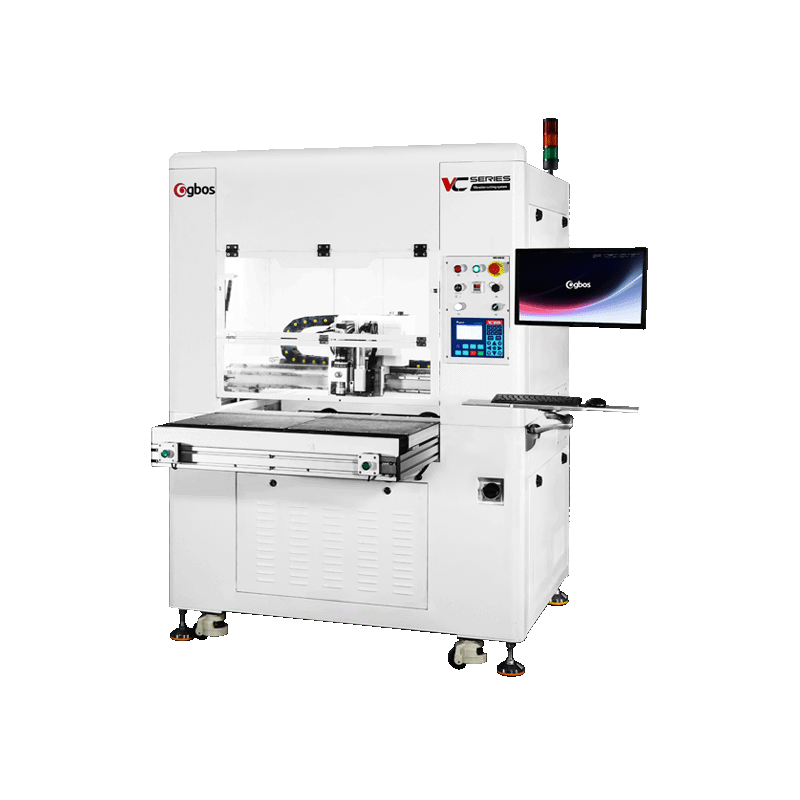

GN1081TT-CCDDouble Heads Async Laser Cutting Machine for Sheet Embroidery Woven LabelsMore Details

GN1081TT-CCDDouble Heads Async Laser Cutting Machine for Sheet Embroidery Woven LabelsMore Details

-

May 22,2025

In today’s consumer market, the demand for product quality is steadily rising. Nowadays, when purchasing items such as clothing and footwear, consumers are no longer focused solely on style and product quality—their attention to labels and tags is also steadily increasing. Labels Under Upgraded Quality Demands A well-designed and finely crafted label is not only a brand identifier but also a key factor for consumers when assessing product quality. Products with strong label presence often win greater consumer favor. This shift has brought unprecedented development opportunities to the label industry, while also placing higher demands on manufacturers. A Dual Challenge of Craftsmanship and Production For manufacturers, today’s market demands are becoming increasingly complex. From a craftsmanship perspective, different types of labels have unique requirements for cutting and processing. Woven labels require precise cutting techniques to ensure clean edges and clear patterns. Printed labels demand high cutting accuracy while preserving the integrity of the printed design. Layered labels challenge the equipment’s ability to handle materials with varying thicknesses. As for printed ribbons, cutting must maintain the ribbon’s integrity while achieving diverse cutting shapes. At the same time, the growing demand for labels requires manufacturers to significantly boost production efficiency without compromising...

In today’s consumer market, the demand for product quality is steadily rising. Nowadays, when purchasing items such as clothing and footwear, consumers are no longer focused solely on style and product quality—their attention to labels and tags is also steadily increasing. Labels Under Upgraded Quality Demands A well-designed and finely crafted label is not only a brand identifier but also a key factor for consumers when assessing product quality. Products with strong label presence often win greater consumer favor. This shift has brought unprecedented development opportunities to the label industry, while also placing higher demands on manufacturers. A Dual Challenge of Craftsmanship and Production For manufacturers, today’s market demands are becoming increasingly complex. From a craftsmanship perspective, different types of labels have unique requirements for cutting and processing. Woven labels require precise cutting techniques to ensure clean edges and clear patterns. Printed labels demand high cutting accuracy while preserving the integrity of the printed design. Layered labels challenge the equipment’s ability to handle materials with varying thicknesses. As for printed ribbons, cutting must maintain the ribbon’s integrity while achieving diverse cutting shapes. At the same time, the growing demand for labels requires manufacturers to significantly boost production efficiency without compromising... -

Dec 20,2024

Woven mark , like a delicate finishing touch on clothing, is not only a sign of excellent quality and ultimate comfort, but also a carrier of the brand’s unique charm and extraordinary recognition. It is like a bright artistic treasure in clothing design, leading the trend of the wind vane, giving the wearer an endless sense of fashion and personality style. In the pursuit of design diversification, refinement and personalization of the wave, the cutting and processing of woven labels are facing unprecedented challenges. In particular, multi-graphics, multi-style woven labels accurate cutting, has become a major problem for many users of the accessories label industry. PART 01 The beauty and challenge of the art of woven label Just think, an exquisite jacket, its chest or sleeve arm parts of the woven mark label, the color needs to be a perfect blend with the clothing, patterns and text need to be fine and subtle, in order to highlight the unique charm of the brand and high-end texture. However, unfortunately, the traditional woven mark label processing methods, most of which still remain in the manual or simple mechanical cutting stage, these means not only cutting style dull, difficult to accurately and delicately deal...

Woven mark , like a delicate finishing touch on clothing, is not only a sign of excellent quality and ultimate comfort, but also a carrier of the brand’s unique charm and extraordinary recognition. It is like a bright artistic treasure in clothing design, leading the trend of the wind vane, giving the wearer an endless sense of fashion and personality style. In the pursuit of design diversification, refinement and personalization of the wave, the cutting and processing of woven labels are facing unprecedented challenges. In particular, multi-graphics, multi-style woven labels accurate cutting, has become a major problem for many users of the accessories label industry. PART 01 The beauty and challenge of the art of woven label Just think, an exquisite jacket, its chest or sleeve arm parts of the woven mark label, the color needs to be a perfect blend with the clothing, patterns and text need to be fine and subtle, in order to highlight the unique charm of the brand and high-end texture. However, unfortunately, the traditional woven mark label processing methods, most of which still remain in the manual or simple mechanical cutting stage, these means not only cutting style dull, difficult to accurately and delicately deal... -

Jul 29,2024

In today’s era of technological innovation and AI-driven production, the industrial manufacturing sector is experiencing a revolutionary transformation. This transformation focuses on intelligent, automated, and data-driven production models that not only significantly boost productivity but also spark innovation and drive upgrades across the industry. Particularly in the field of flexible manufacturing, the application of AI VisionScan technology has become a key force in replacing manual identification, making various processes more intelligent and precise. This effectively reduces labor costs and promotes the transition from flexible manufacturing to smart manufacturing. 16 Years of AI VisionScan Technology Accumulation GBOS’s emphasis on this technological transformation began in 2008 when we took the first step in developing VisionScan technology. After 16 years of technological accumulation and continuous innovation, we have advanced VisionScan technology to the fifth generation (CCD 5.0). This technology not only theoretically achieves an “AI VisionScan accuracy of ±0.1mm” but also demonstrates tremendous value in practical applications. It has been widely applied in industries such as footwear, apparel, and garment accessories, facilitating the production and processing of same-color mesh fabrics, digitally printed materials, and various types of trademarks, thereby solving many production challenges for users. The “Eye of Wisdom” in the Garment Accessories...

In today’s era of technological innovation and AI-driven production, the industrial manufacturing sector is experiencing a revolutionary transformation. This transformation focuses on intelligent, automated, and data-driven production models that not only significantly boost productivity but also spark innovation and drive upgrades across the industry. Particularly in the field of flexible manufacturing, the application of AI VisionScan technology has become a key force in replacing manual identification, making various processes more intelligent and precise. This effectively reduces labor costs and promotes the transition from flexible manufacturing to smart manufacturing. 16 Years of AI VisionScan Technology Accumulation GBOS’s emphasis on this technological transformation began in 2008 when we took the first step in developing VisionScan technology. After 16 years of technological accumulation and continuous innovation, we have advanced VisionScan technology to the fifth generation (CCD 5.0). This technology not only theoretically achieves an “AI VisionScan accuracy of ±0.1mm” but also demonstrates tremendous value in practical applications. It has been widely applied in industries such as footwear, apparel, and garment accessories, facilitating the production and processing of same-color mesh fabrics, digitally printed materials, and various types of trademarks, thereby solving many production challenges for users. The “Eye of Wisdom” in the Garment Accessories... -

Mar 30,2023

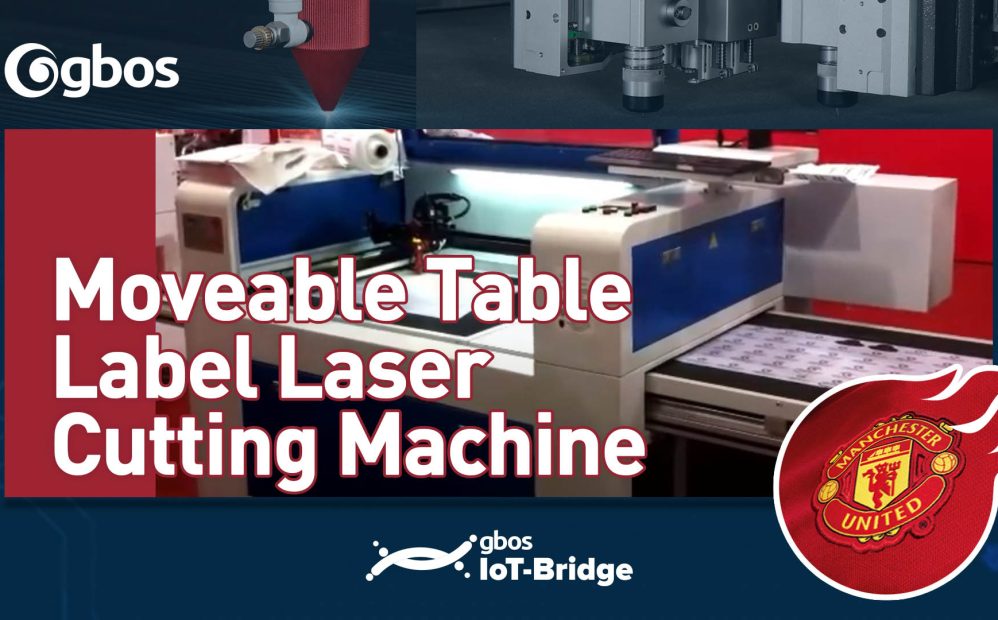

August 5th, 2023, GBOS headquarter, hold smart label laser cutting application. Provide you: Half labor required & Double capacity. All customers came our fully innovation conference are label industry topping leaders, they use our long lifespan laser label cutting machine all the time! Also, other top leading brand give great praise for our machines. Like: SML, Avery Dennison, Lion brother, Li Fung, etc. Now, they start communicating with ” 5.0 New Generation Breakthrough Machine”. How to achieve “Half labor required & Double capacity”, “Labor Replacement”? What the trend for future? They start a meaningful communication. 2021 newest laser cutting solutions for various of labels (Woven label, embroidery patches, heat transfer label, printed label, etc). Product Reviewing: 1) New product publish, GN1080CCD-AT. Auto-feeding laser cutting machine for roll labels! Half labor required, 1 person can operate 5 machines! 2) New product publish, GN1081TT-CCD. Double heads async laser cutting for sheet woven & embroidery patches label! Double capacity. 3) XXP3.1-180-CCD, Multi-label high speed laser marking & cutting machine for heat transfer label, woven labels, and more customized labels. This is the model of the trend for the future! 4) FB07CCD, Automatic soldering iron edge burning machine. 1 person operate 10 units machine, and labor replacement, free...

August 5th, 2023, GBOS headquarter, hold smart label laser cutting application. Provide you: Half labor required & Double capacity. All customers came our fully innovation conference are label industry topping leaders, they use our long lifespan laser label cutting machine all the time! Also, other top leading brand give great praise for our machines. Like: SML, Avery Dennison, Lion brother, Li Fung, etc. Now, they start communicating with ” 5.0 New Generation Breakthrough Machine”. How to achieve “Half labor required & Double capacity”, “Labor Replacement”? What the trend for future? They start a meaningful communication. 2021 newest laser cutting solutions for various of labels (Woven label, embroidery patches, heat transfer label, printed label, etc). Product Reviewing: 1) New product publish, GN1080CCD-AT. Auto-feeding laser cutting machine for roll labels! Half labor required, 1 person can operate 5 machines! 2) New product publish, GN1081TT-CCD. Double heads async laser cutting for sheet woven & embroidery patches label! Double capacity. 3) XXP3.1-180-CCD, Multi-label high speed laser marking & cutting machine for heat transfer label, woven labels, and more customized labels. This is the model of the trend for the future! 4) FB07CCD, Automatic soldering iron edge burning machine. 1 person operate 10 units machine, and labor replacement, free...

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: