-

Industry Trends/Customer Challenges

Industry Trends/Customer ChallengesCost Pressure: The shoe industry faces challenges with higher raw material costs, increased labor expenses, and supply chain uncertainties. Finding cost-effective cutting methods is a big challenge.

Complex Materials: Shoes are made from various materials like leather, rubber, and synthetic leather, each with different properties. Cutting them correctly can be complicated, requiring adaptable cutting techniques.

Precision and Consistency: Shoe manufacturing demands precise and consistent cutting to ensure high-quality and comfortable products.

Small, Diversify, Customized Orders: Requires the factories must deliver the goods in time, in order to catching the "fast fashion" trend.

Sustainability: The increased demand for sustainable footwear is a trend that is gaining traction in the global market.

Digital Cutting Technology: Many shoe manufacturers are using digital cutting technology to boost production efficiency, reduce waste, and enhance product quality. This is a growing trend in the industry.

-

Advantages of GBOS Solutions

Advantages of GBOS SolutionsGBOS offers "One-stop Intelligent Cutting + Innovative Process Solution" to face challenges in the footwear industry, achieving efficient, precise, and sustainable production, and enhancing production efficiency.

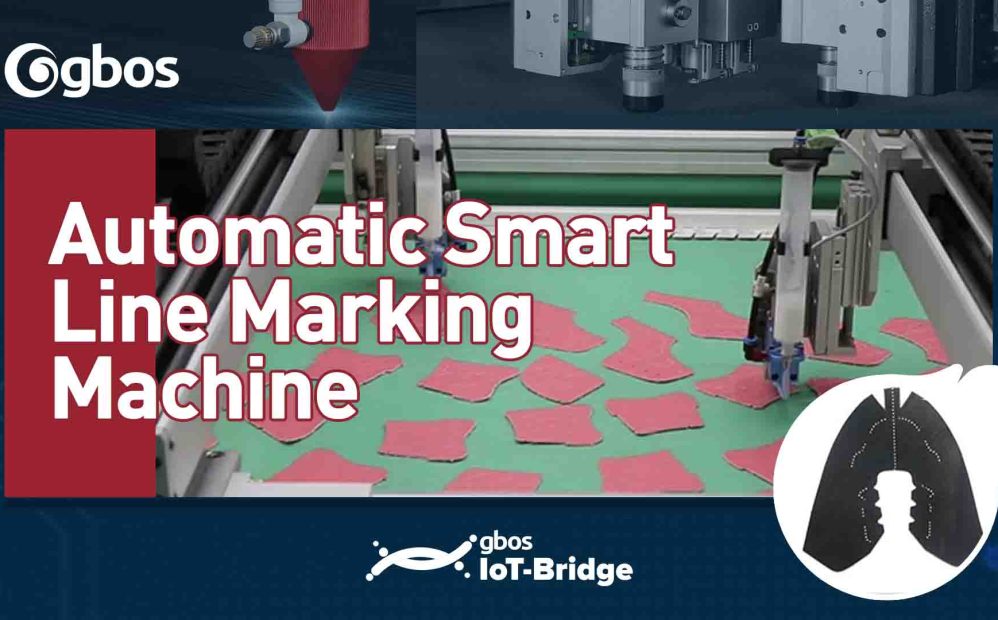

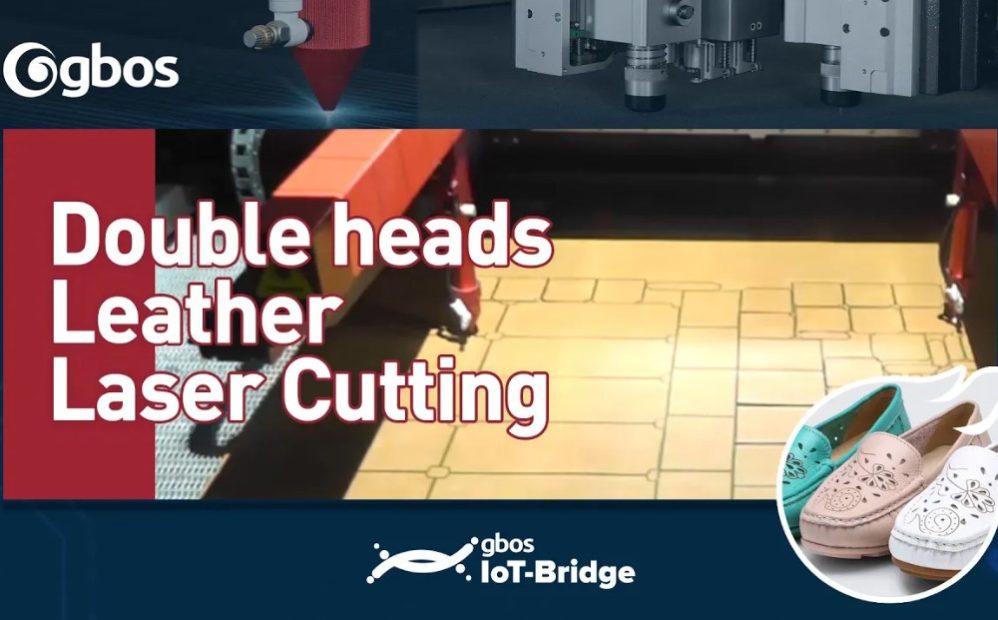

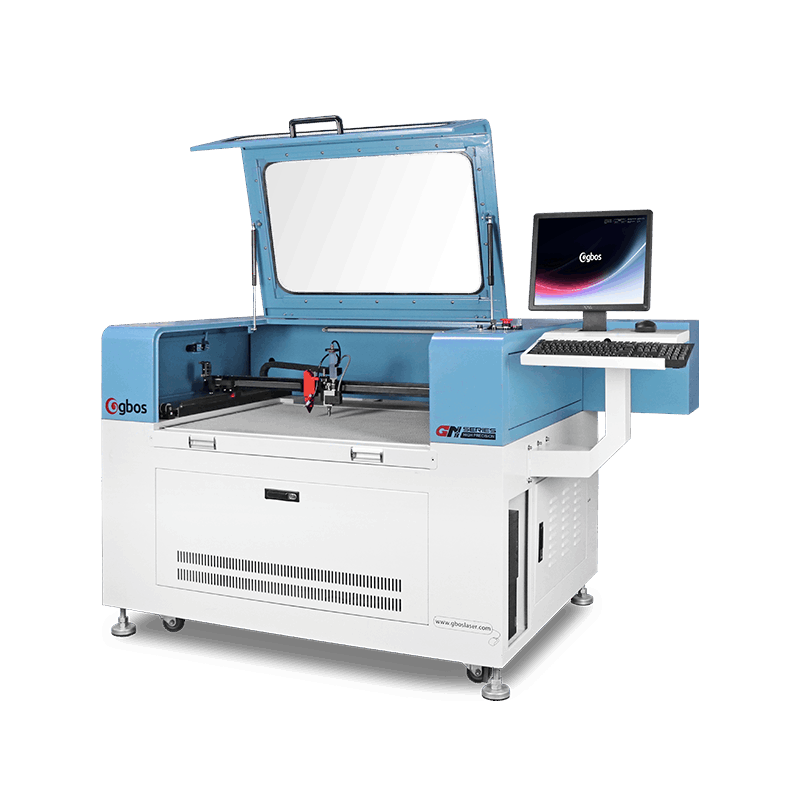

Comprehensive Solutions: CO2 laser cutter for any shoe components; Galvanometer laser marking/engraving/perforating/hollowing/cutting solution for any special customized effects and unique creativity; Auto line marking solution(replace traditional silk screen printing line); AI-Driven solution; Robot; etc.

Less is More: Less labor, less cost, less material waste, and zero cutting-dies!

- Shoe Accessories Laser Cutting

- Shoe Accessories Laser Marking

- Shoe Accessories Auto Line Marking

- Shoe Mold Laser Engraivng

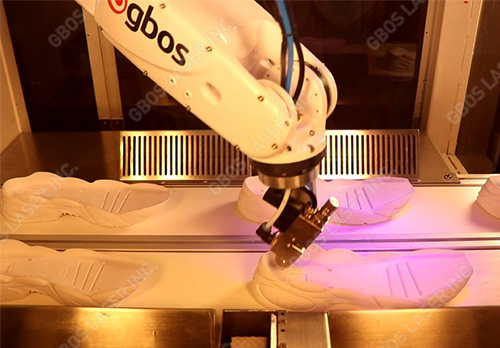

- Robot Shoe Sole Glue Spraying

- Sublimation Printed Fabric Laser Cutting

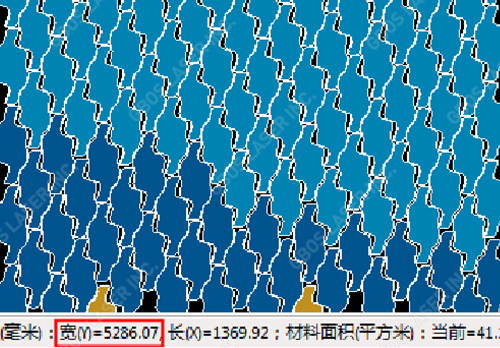

- Auto Nesting for Regular Material

- AI Leather Nesting

-

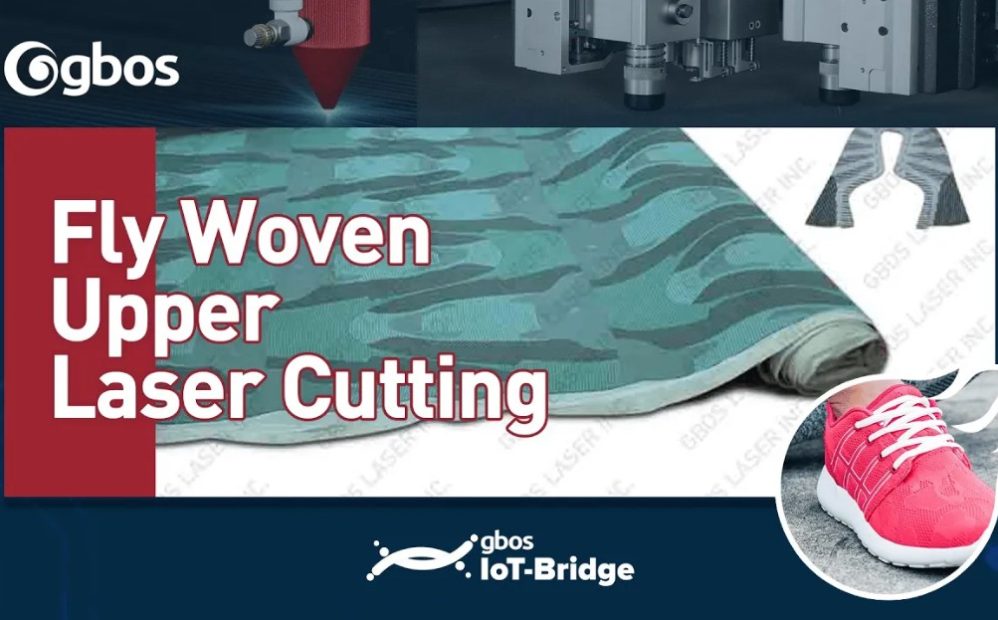

Fly Kintted Woven Shoe Upper Laser Cutting

Fly Kintted Woven Shoe Upper Laser Cutting -

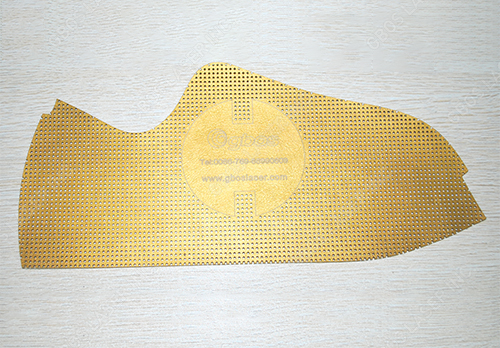

Mesh Sole Laser Cutting

Mesh Sole Laser Cutting -

Leather Laser Cutting

Leather Laser Cutting -

Leather Shoe Upper Laser Cutting

Leather Shoe Upper Laser Cutting -

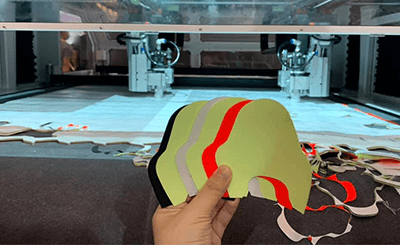

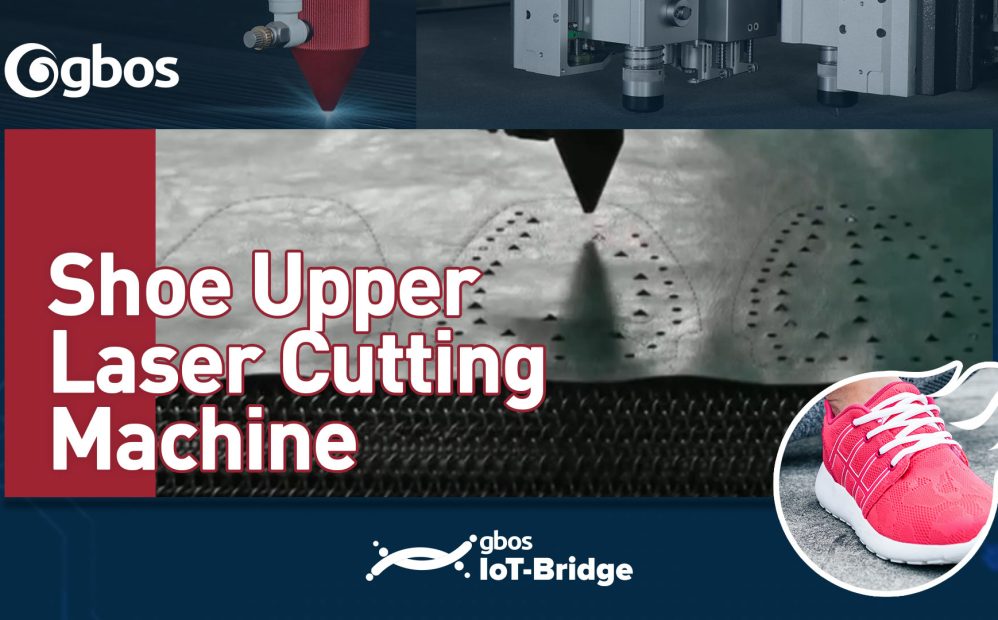

Mesh Shoe Upper Laser Cutting

Mesh Shoe Upper Laser Cutting -

Shoe Accessories Laser Cutting

Shoe Accessories Laser Cutting -

Shoe Accessories Laser Cutting

Shoe Accessories Laser Cutting -

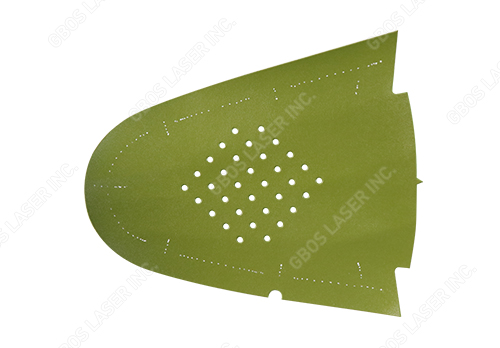

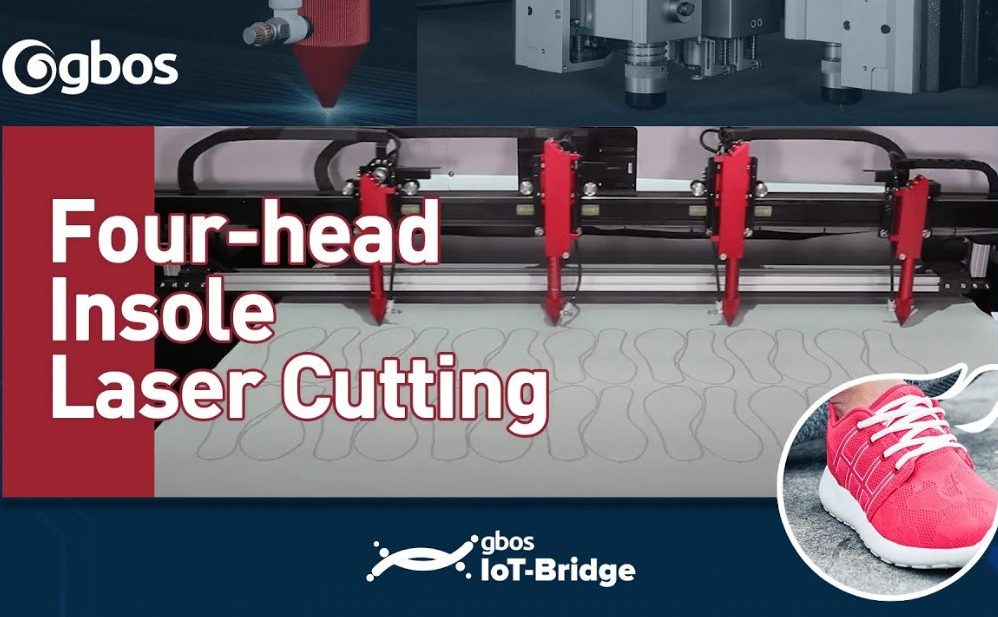

Shoe Insole Laser Cutting

Shoe Insole Laser Cutting -

Laser Cutting for Sandal Shoe Accesorries

Laser Cutting for Sandal Shoe Accesorries -

Shoe Accessories Laser Cutting

Shoe Accessories Laser Cutting

-

Shoe Sole Laser Marking

Shoe Sole Laser Marking -

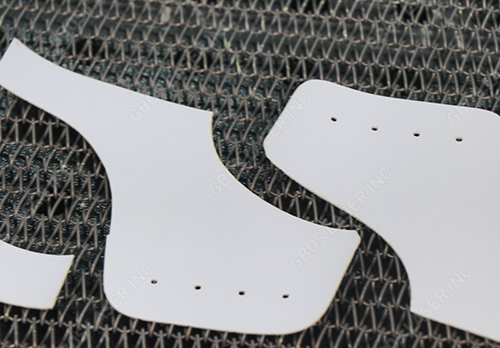

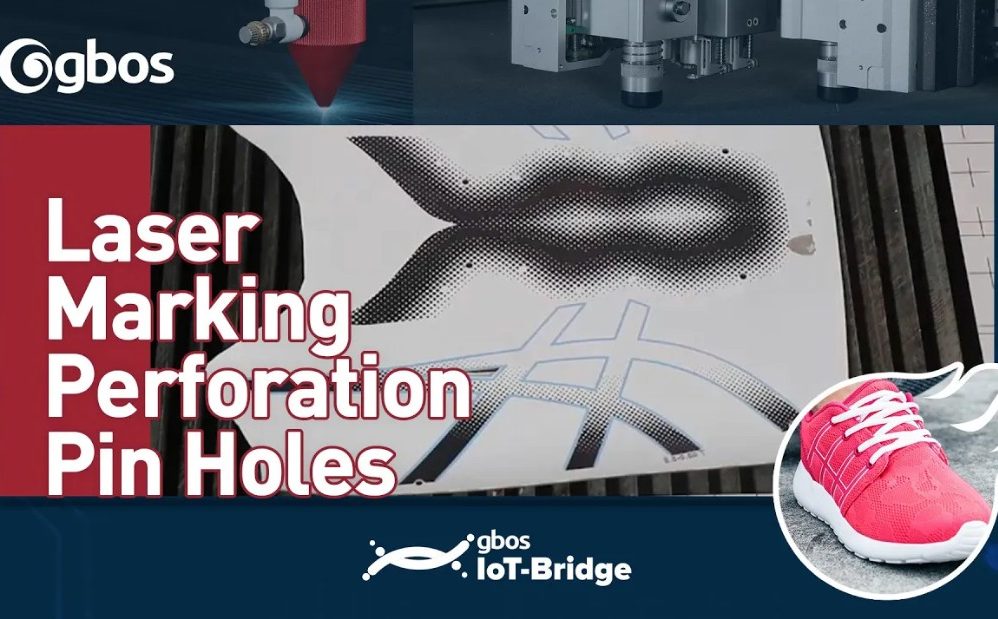

Laser Marking PU Shoe Positioning Hole

Laser Marking PU Shoe Positioning Hole -

Laser Marking Shoe Positioning Hole

Laser Marking Shoe Positioning Hole -

Laser Cutting Marking Shoe Accessories

Laser Cutting Marking Shoe Accessories -

Leather Jacket Laser Marking

Leather Jacket Laser Marking -

UV Laser Marking Leather

UV Laser Marking Leather -

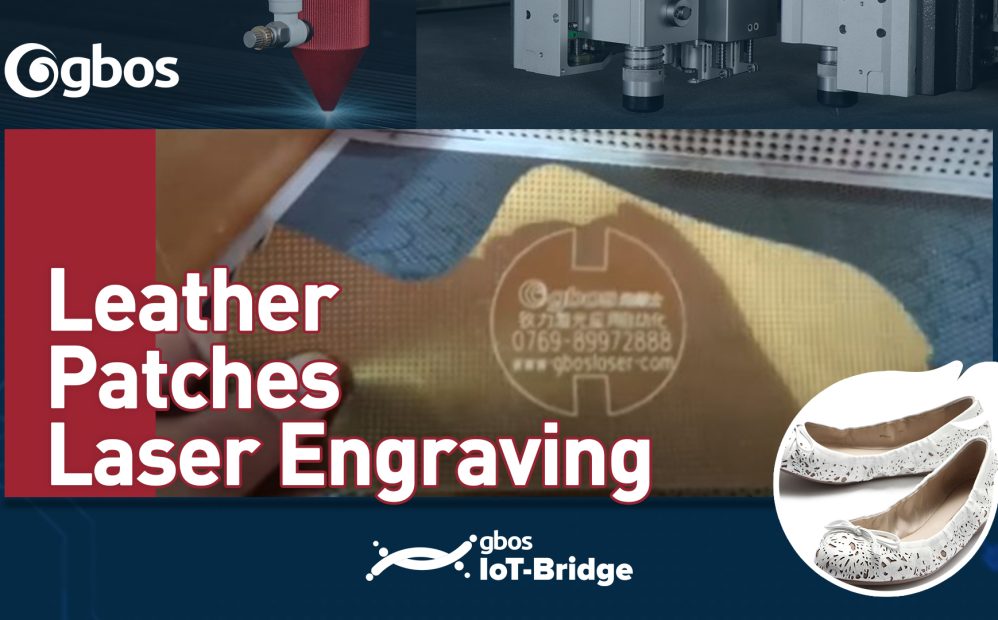

Laser Engraving Cutting Leather Label

Laser Engraving Cutting Leather Label -

Laser Cutting Engraving Leather

Laser Cutting Engraving Leather -

Leather Shoe Upper Laser Cutting

Leather Shoe Upper Laser Cutting -

Laser Cutting Sandals Shoe Accessories

Laser Cutting Sandals Shoe Accessories -

Shoe Sole Laser Marking Machine

Shoe Sole Laser Marking Machine -

Sports Shoe Sole Laser Marking

Sports Shoe Sole Laser Marking -

Sports Shoe Sole Laser Marking

Sports Shoe Sole Laser Marking -

Sandal Shoe Sole Laser Marking

Sandal Shoe Sole Laser Marking -

Ballet Shoe Sole Laser Marking

Ballet Shoe Sole Laser Marking -

Ballet Shoe Sole Laser Marking

Ballet Shoe Sole Laser Marking -

Shoe Sole Laser Marking

Shoe Sole Laser Marking -

Laser Engaving for Shoe Accessories

Laser Engaving for Shoe Accessories

-

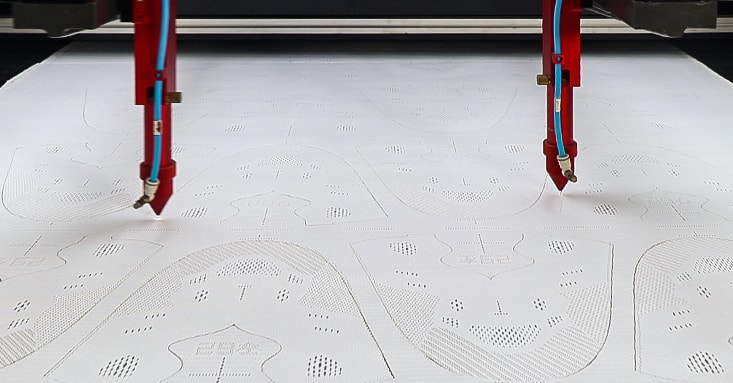

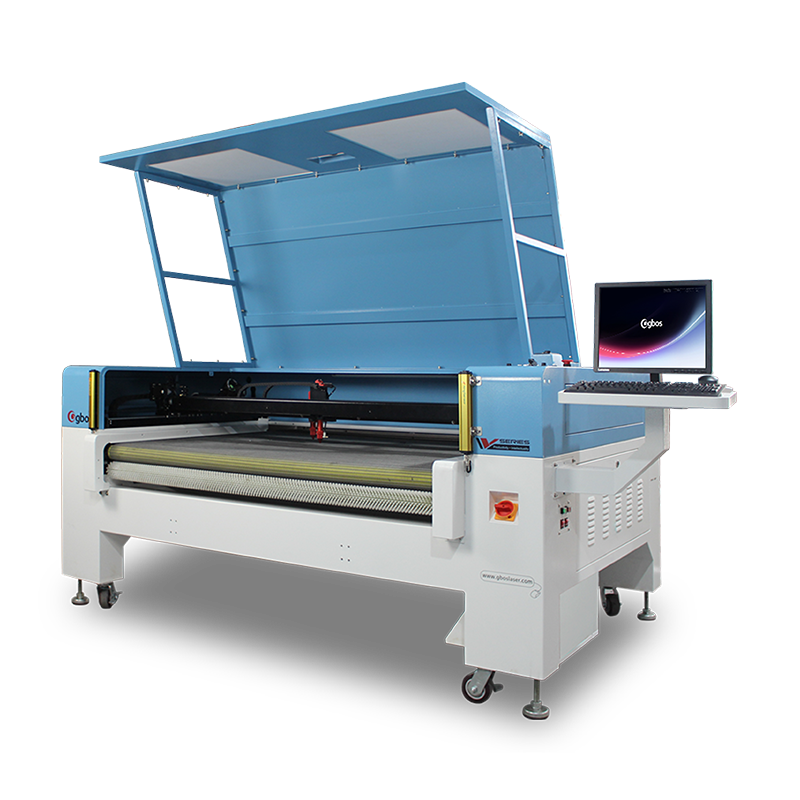

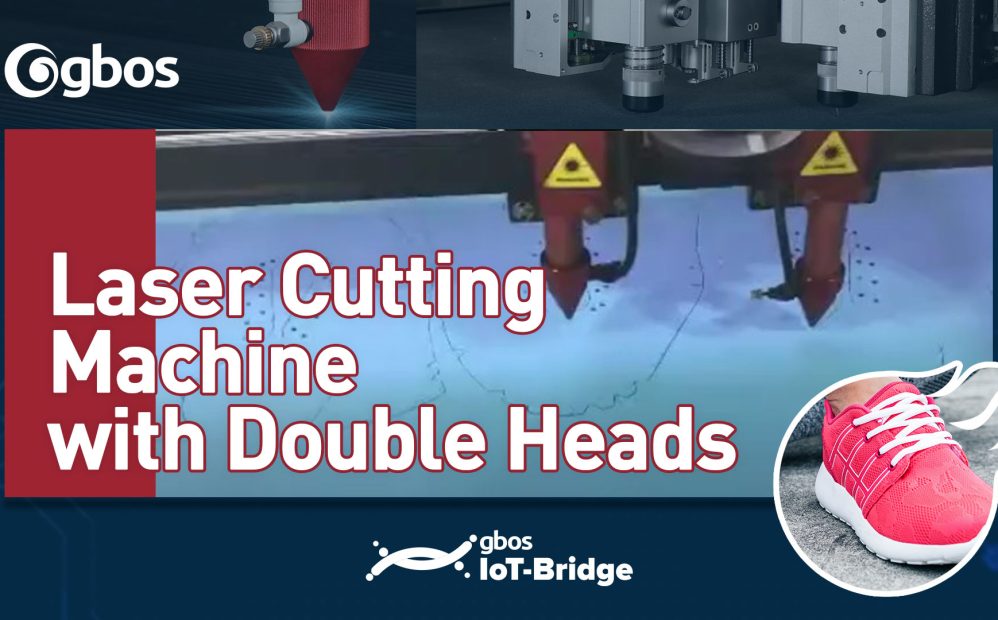

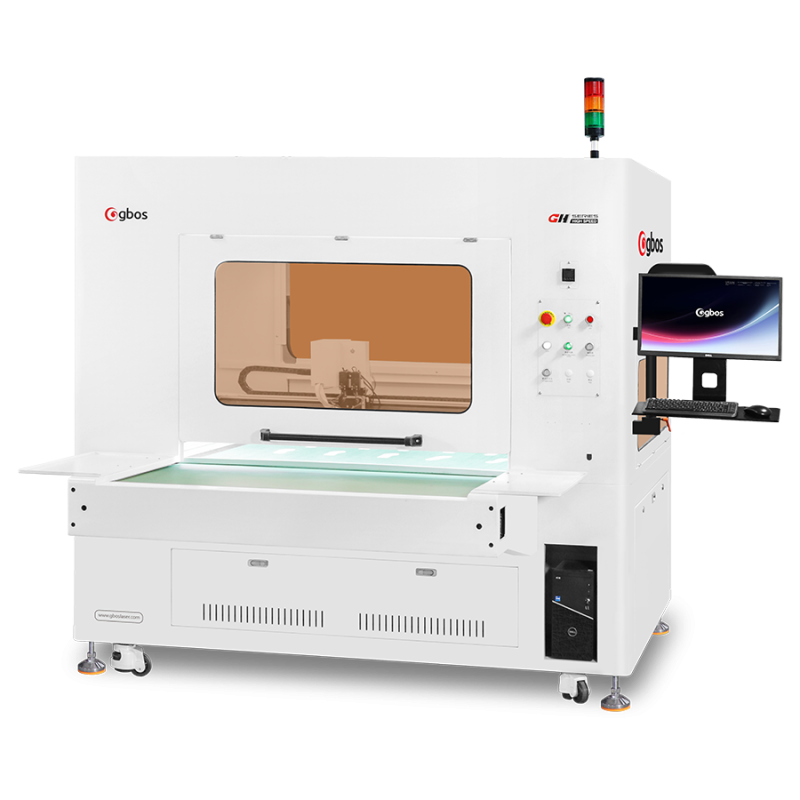

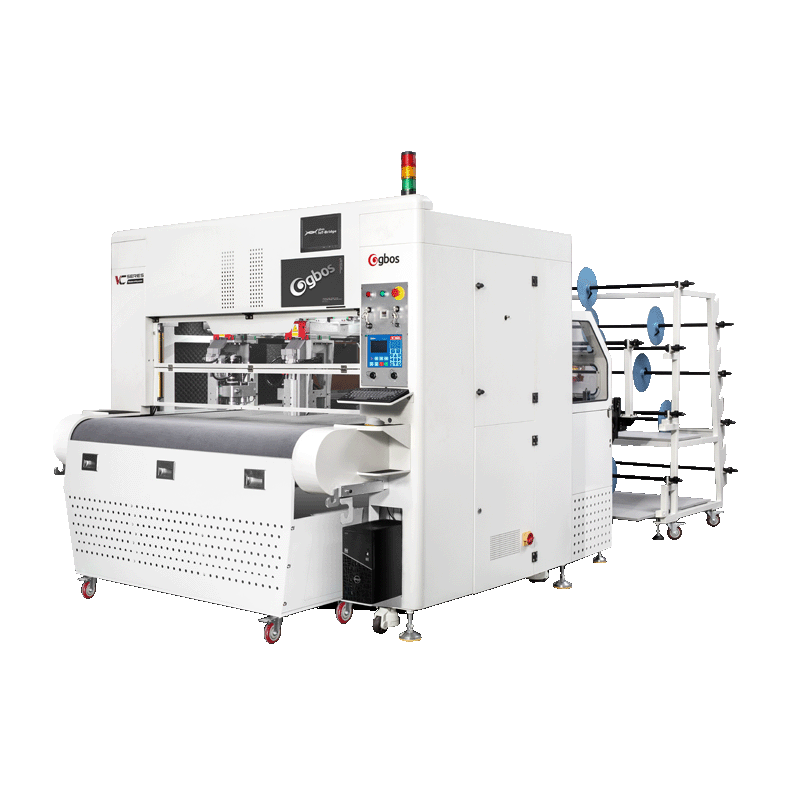

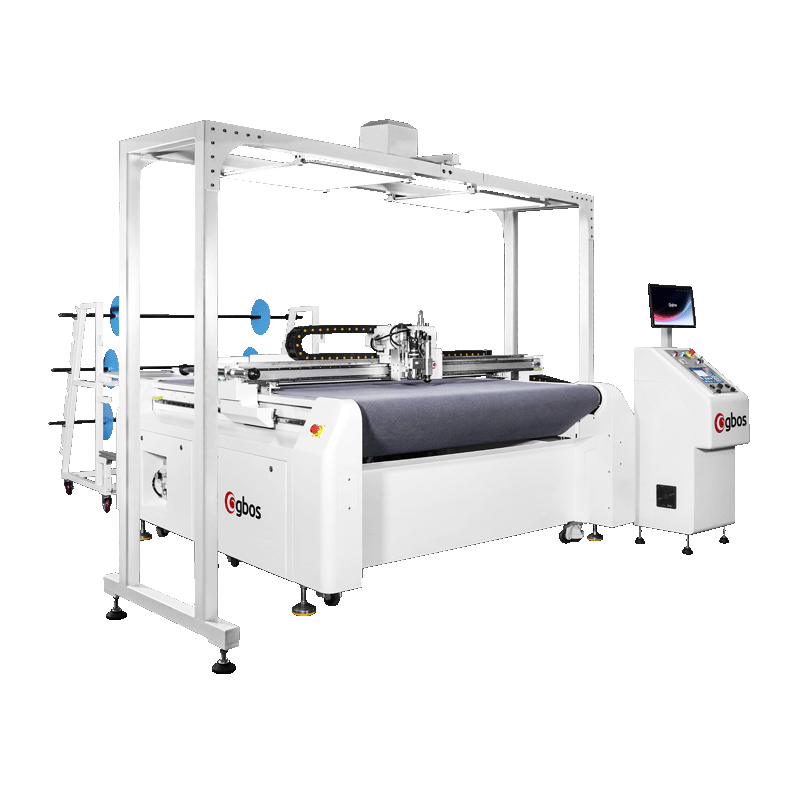

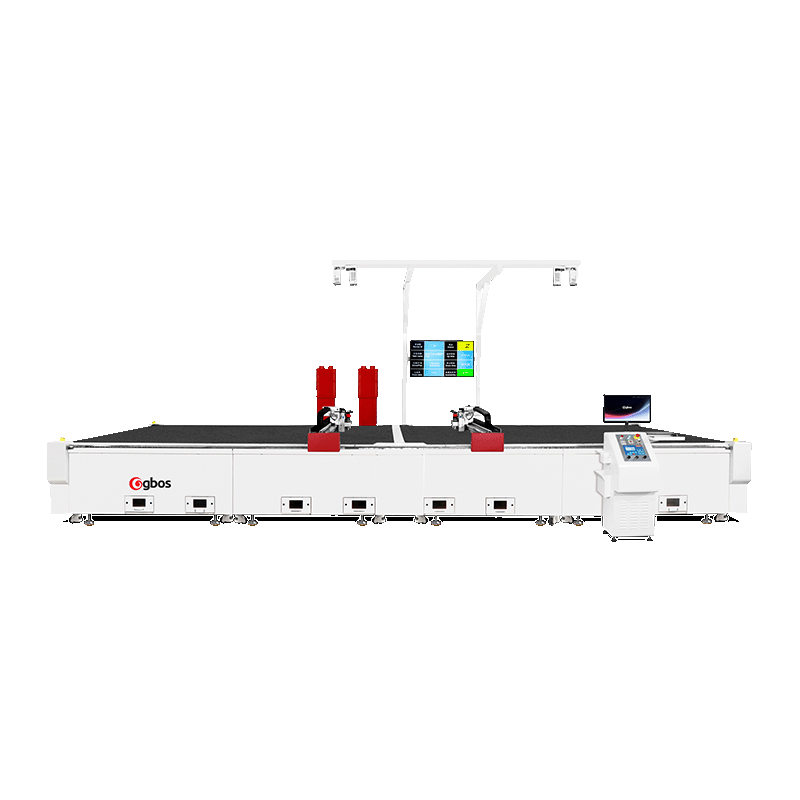

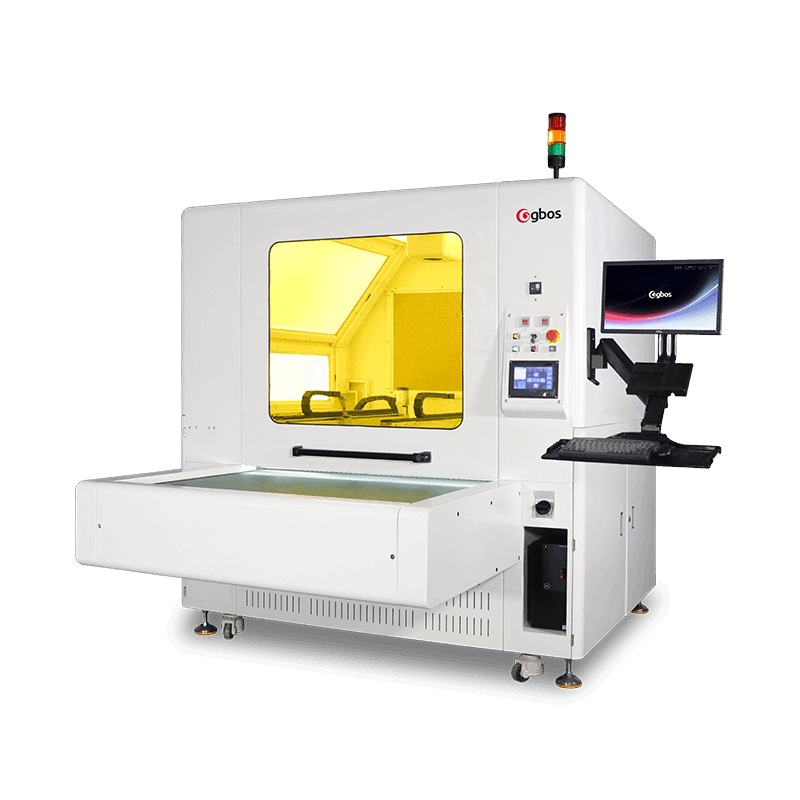

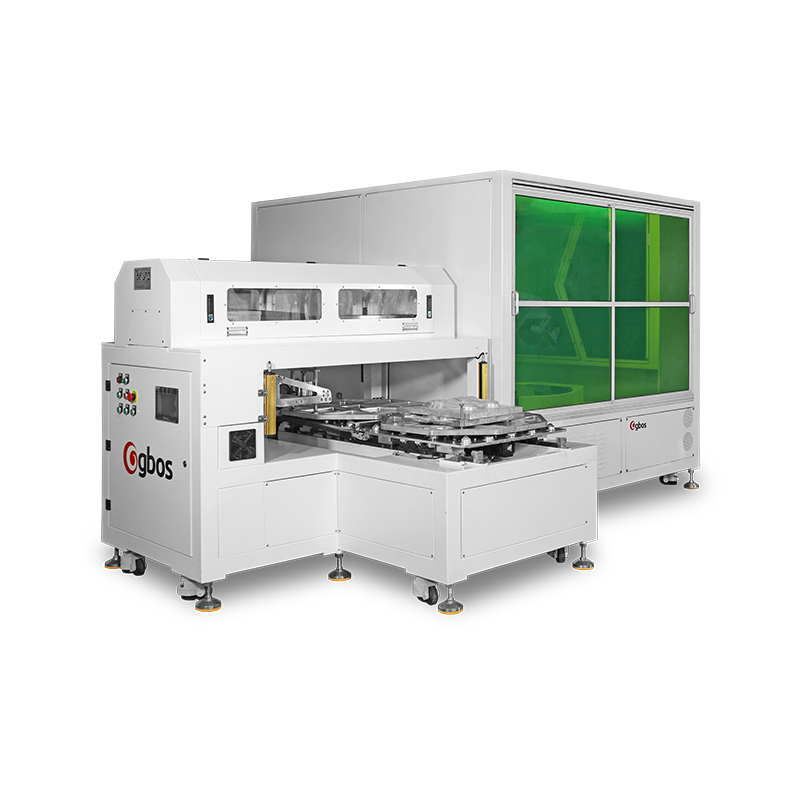

GH1812(TT)-AT-SCCDTwo Heads Asynchronous Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

GH1812(TT)-AT-SCCDTwo Heads Asynchronous Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

-

Nov 25,2025

As temperatures drop, the seasonal demand for footwear rises. Leather shoes and boots—valued for their warmth and versatile texture—have become essential staples for autumn and winter outfits. No matter whether it’s business commuting, casual daily wear, or the functional needs of outdoor activities, premium leather shoes and boots adapt effortlessly to every scenario. Consumers’ expectations for footwear have evolved into a unified demand for style, comfort, and durability. They seek refined design while valuing material quality and overall wearing experience. This shift is accelerating the footwear industry’s move toward high-quality, precision manufacturing—opening significant market opportunities for advanced production equipment. 01 Shoe Manufacturing Faces the Pressure of Quality and Capacity Demands With autumn and winter orders surging, footwear manufacturers are facing multiple production challenges.In terms of efficiency, In terms of efficiency, traditional cutting equipment struggles to handle the mass processing of multiple components—such as leather shoe uppers and boot linings—making tight delivery schedules even more challenging. On the cost side, leather prices remain high, while manual nesting and cutting result in a high waste rate—further squeezing profit margins. On the quality side, inconsistencies in cutting accuracy across different production batches can lead to issues such as shape deviation and poor component...

As temperatures drop, the seasonal demand for footwear rises. Leather shoes and boots—valued for their warmth and versatile texture—have become essential staples for autumn and winter outfits. No matter whether it’s business commuting, casual daily wear, or the functional needs of outdoor activities, premium leather shoes and boots adapt effortlessly to every scenario. Consumers’ expectations for footwear have evolved into a unified demand for style, comfort, and durability. They seek refined design while valuing material quality and overall wearing experience. This shift is accelerating the footwear industry’s move toward high-quality, precision manufacturing—opening significant market opportunities for advanced production equipment. 01 Shoe Manufacturing Faces the Pressure of Quality and Capacity Demands With autumn and winter orders surging, footwear manufacturers are facing multiple production challenges.In terms of efficiency, In terms of efficiency, traditional cutting equipment struggles to handle the mass processing of multiple components—such as leather shoe uppers and boot linings—making tight delivery schedules even more challenging. On the cost side, leather prices remain high, while manual nesting and cutting result in a high waste rate—further squeezing profit margins. On the quality side, inconsistencies in cutting accuracy across different production batches can lead to issues such as shape deviation and poor component... -

Nov 05,2025

In the manufacturing sectors of shoes, luggage, automotive interiors, and sofa furniture, enterprises are increasingly challenged by high labor costs, low efficiency, and unstable precision in mass production. These persistent pain points have become major “stumbling blocks” for businesses striving to gain a competitive edge in the market. From the heavy reliance on skilled workers for sorting cut pieces to inefficient cutting processes that can’t keep up with order demands — and from excessive leather waste driving up costs to cluttered work areas caused by leftover materials — these issues not only restrict production capacity but also hinder overall competitiveness. 01. Bottlenecks in Traditional Mass Production In the shoe manufacturing industry, traditional production lines require significant manual labor to sort and handle cut pieces. Each skilled worker can only process a limited volume daily, and fatigue from long hours often leads to sorting errors, resulting in costly rework in later stages. In luggage production, manual positioning during leather cutting introduces variability, as different workers have distinct operation habits. This inconsistency leads to inaccurate cuts, material waste, and additional costs to correct defective products. Furthermore, the absence of efficient marking systems in traditional workflows makes it difficult to identify and match...

In the manufacturing sectors of shoes, luggage, automotive interiors, and sofa furniture, enterprises are increasingly challenged by high labor costs, low efficiency, and unstable precision in mass production. These persistent pain points have become major “stumbling blocks” for businesses striving to gain a competitive edge in the market. From the heavy reliance on skilled workers for sorting cut pieces to inefficient cutting processes that can’t keep up with order demands — and from excessive leather waste driving up costs to cluttered work areas caused by leftover materials — these issues not only restrict production capacity but also hinder overall competitiveness. 01. Bottlenecks in Traditional Mass Production In the shoe manufacturing industry, traditional production lines require significant manual labor to sort and handle cut pieces. Each skilled worker can only process a limited volume daily, and fatigue from long hours often leads to sorting errors, resulting in costly rework in later stages. In luggage production, manual positioning during leather cutting introduces variability, as different workers have distinct operation habits. This inconsistency leads to inaccurate cuts, material waste, and additional costs to correct defective products. Furthermore, the absence of efficient marking systems in traditional workflows makes it difficult to identify and match... -

May 27,2025

From the meticulously hand-stitched traditional cloth shoes to the mass-produced athletic footwear churned out by assembly lines, the footwear industry has undergone centuries of evolution and transformation. As the pace of industrialization quickens, cost control has emerged as the linchpin of corporate competition, fueling the prevalence of large-scale standardized production. New directions under the changing needs of the times In the early days, consumers’ demand for shoes was mainly focused on meeting daily wear, and footwear enterprises pursued production volume to satisfy the huge market demand. Today, consumer demands have become increasingly diversified and personalized. People are no longer satisfied with the basic functions of shoes alone, but have higher requirements for design and environmental protection. This series of demand changes has prompted the footwear industry to continuously explore new development directions. The Imminent Challenges Facing Manufacturers In the transformation of footwear products from “output priority” to “cost control” and now to the era where “production capacity, cost, innovation, and environmental protection go hand in hand”, footwear enterprises are faced with numerous challenges. Traditional production equipment and processes struggle to meet complex and diverse design requirements. When handling multi-layer foams and composite materials, low cutting precision and poor efficiency lead...

From the meticulously hand-stitched traditional cloth shoes to the mass-produced athletic footwear churned out by assembly lines, the footwear industry has undergone centuries of evolution and transformation. As the pace of industrialization quickens, cost control has emerged as the linchpin of corporate competition, fueling the prevalence of large-scale standardized production. New directions under the changing needs of the times In the early days, consumers’ demand for shoes was mainly focused on meeting daily wear, and footwear enterprises pursued production volume to satisfy the huge market demand. Today, consumer demands have become increasingly diversified and personalized. People are no longer satisfied with the basic functions of shoes alone, but have higher requirements for design and environmental protection. This series of demand changes has prompted the footwear industry to continuously explore new development directions. The Imminent Challenges Facing Manufacturers In the transformation of footwear products from “output priority” to “cost control” and now to the era where “production capacity, cost, innovation, and environmental protection go hand in hand”, footwear enterprises are faced with numerous challenges. Traditional production equipment and processes struggle to meet complex and diverse design requirements. When handling multi-layer foams and composite materials, low cutting precision and poor efficiency lead... -

Mar 31,2025

From March 17 to 18, the Vietnam & ASEAN Footwear Summit grandly commenced and successfully concluded in the vibrant and opportunity-filled city of Ho Chi Minh. As a premier regional footwear industry event, the summit served as a bridge connecting global footwear elites. It attracted industry leaders, top technical experts, and outstanding representatives from all sectors of the supply chain across multiple countries. With its increasing international presence and industry influence, the event reached new heights, continuously injecting innovation and momentum into the global footwear industry’s development. During the summit, representatives from footwear associations in Vietnam, Indonesia, Cambodia, and other regions took the stage to share professional insights and in-depth analysis. They explored the complexities of global footwear trade, the potential impact of tariff barriers, and the disruptive transformations brought by cutting-edge technologies such as artificial intelligence. These topics are closely tied to the growth of export and global expansion enterprises, sparking intense discussions and deep exchanges among attendees—like a stone cast into a calm lake, igniting a surge of ideas and innovation. As a pioneering leader in flexible intelligent manufacturing, GBOS was invited to shine at the summit in both guest and sponsor roles, showcasing its outstanding achievements and...

From March 17 to 18, the Vietnam & ASEAN Footwear Summit grandly commenced and successfully concluded in the vibrant and opportunity-filled city of Ho Chi Minh. As a premier regional footwear industry event, the summit served as a bridge connecting global footwear elites. It attracted industry leaders, top technical experts, and outstanding representatives from all sectors of the supply chain across multiple countries. With its increasing international presence and industry influence, the event reached new heights, continuously injecting innovation and momentum into the global footwear industry’s development. During the summit, representatives from footwear associations in Vietnam, Indonesia, Cambodia, and other regions took the stage to share professional insights and in-depth analysis. They explored the complexities of global footwear trade, the potential impact of tariff barriers, and the disruptive transformations brought by cutting-edge technologies such as artificial intelligence. These topics are closely tied to the growth of export and global expansion enterprises, sparking intense discussions and deep exchanges among attendees—like a stone cast into a calm lake, igniting a surge of ideas and innovation. As a pioneering leader in flexible intelligent manufacturing, GBOS was invited to shine at the summit in both guest and sponsor roles, showcasing its outstanding achievements and... -

Dec 26,2024

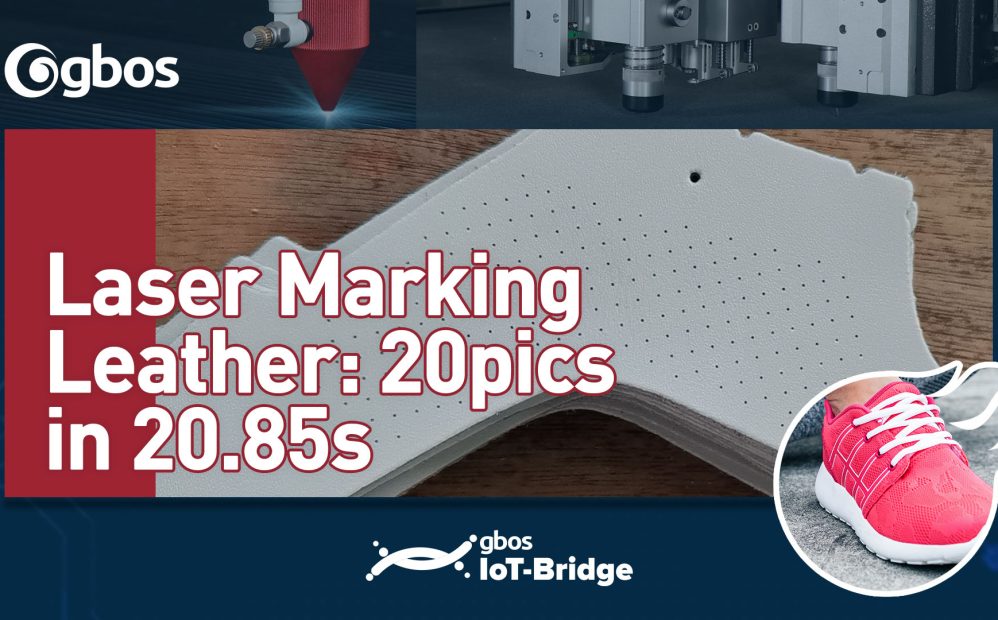

![Walking is not only the art of walking, but also [wisdom]. Walking is not only the art of walking, but also [wisdom].](https://www.gboslaser.com/wp-content/uploads/2024/12/12261-457x270.webp) The sports shoes market, a fertile land full of vigor and innovation, is interpreting the perfect fusion of functionality, fashion and comfort at an unprecedented speed. Each pair of shoes is not only a walking companion, but also a display of personality and taste. 01 The Dilemma of Traditional Craftsmanship: An In-Depth Analysis of Limitations Going back in time, workers on the factory floor, armed with hammers and nails, performed punching tasks by hand with pure skill. This not only tests their patience and precision, but is also a fond look back at the traditional manufacturing model. However, the shortcomings of manual punching should not be ignored: the size of the hole is difficult to standardize, and precision control has become a problem; the operational efficiency is low, and it is difficult to match the speed of the modern production line; coupled with the potential damage to the material by manual operation, each batch of products is like a gemstone that has not been meticulously carved and lacks uniform norms and aesthetic value, and it is difficult to satisfy the contemporary consumer’s expectations for the double quality and efficiency. (Traditional manufacturing methods) 02 Innovation Process,Defining new standards Against this background,...

The sports shoes market, a fertile land full of vigor and innovation, is interpreting the perfect fusion of functionality, fashion and comfort at an unprecedented speed. Each pair of shoes is not only a walking companion, but also a display of personality and taste. 01 The Dilemma of Traditional Craftsmanship: An In-Depth Analysis of Limitations Going back in time, workers on the factory floor, armed with hammers and nails, performed punching tasks by hand with pure skill. This not only tests their patience and precision, but is also a fond look back at the traditional manufacturing model. However, the shortcomings of manual punching should not be ignored: the size of the hole is difficult to standardize, and precision control has become a problem; the operational efficiency is low, and it is difficult to match the speed of the modern production line; coupled with the potential damage to the material by manual operation, each batch of products is like a gemstone that has not been meticulously carved and lacks uniform norms and aesthetic value, and it is difficult to satisfy the contemporary consumer’s expectations for the double quality and efficiency. (Traditional manufacturing methods) 02 Innovation Process,Defining new standards Against this background,... -

Dec 10,2024

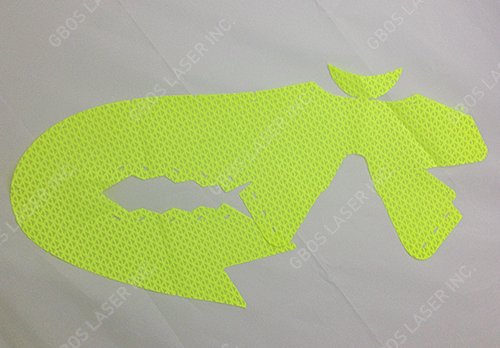

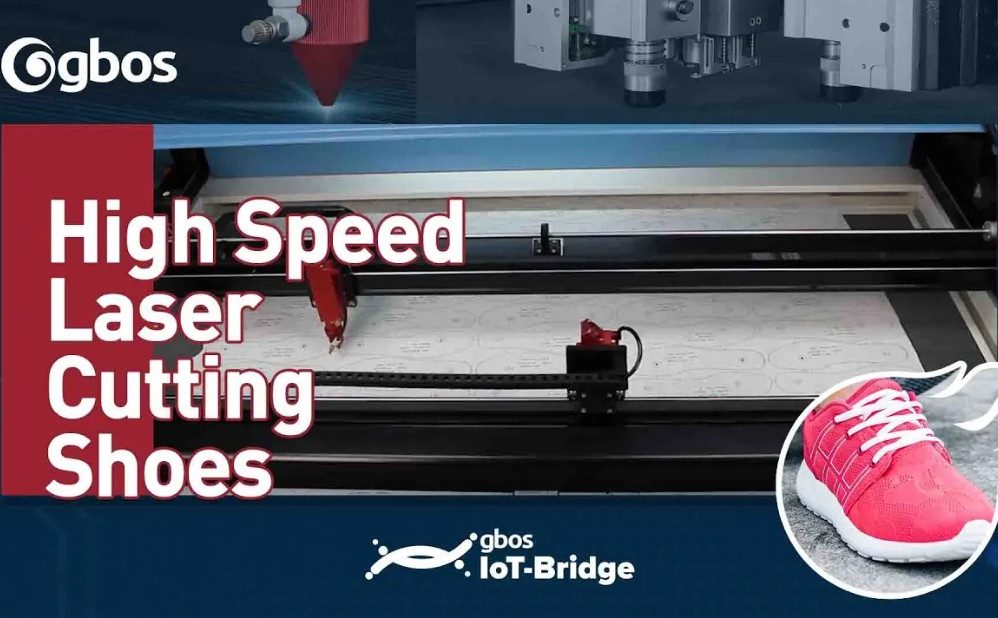

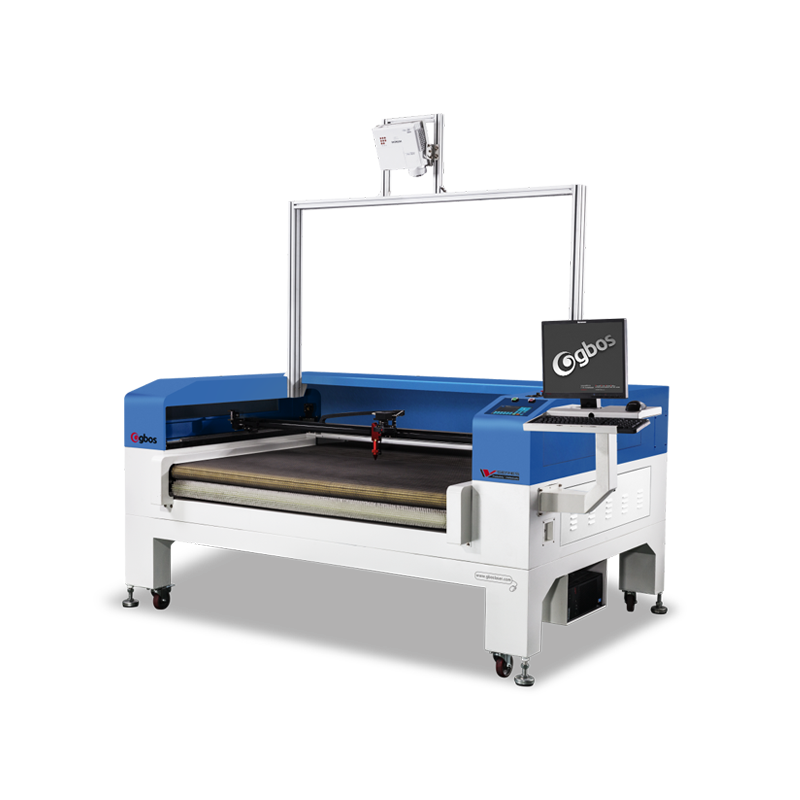

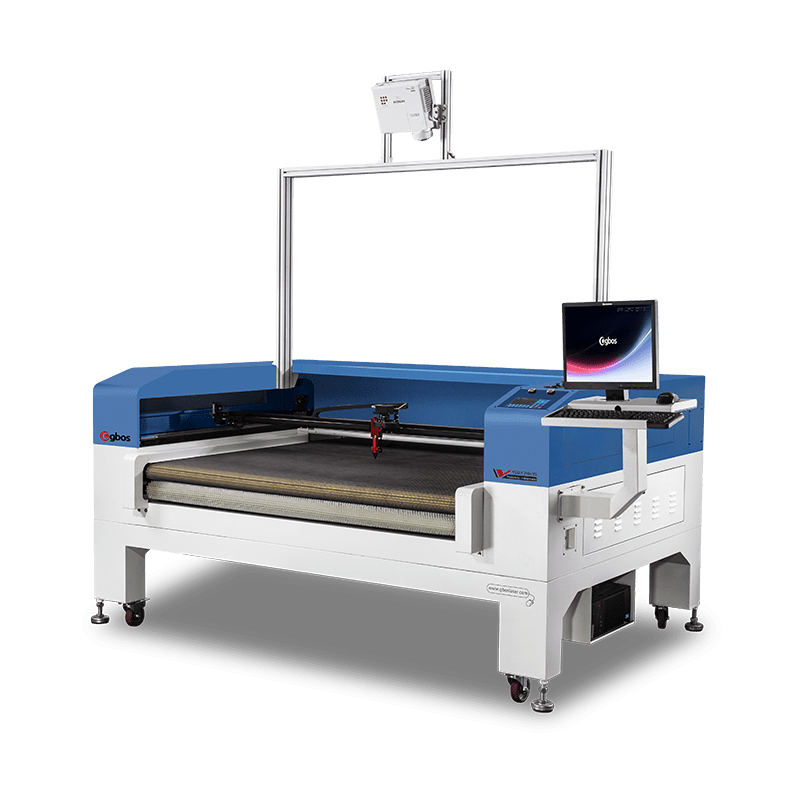

In the vibrant and energetic city, more and more people choose running as a way to release pressure and enjoy life. From the quiet park trails in the morning to the illuminated riverside walkways at night, people who love sports are everywhere. However, for runners, a pair of suitable sneakers is crucial. It should not only meet the functional needs of running, but also be able to show fashion, trend and versatility. In recent years, the same-color mesh material has become a highlight in sneaker design with its unique visual effect and lightweight texture. Through the fine preparation process, this material cleverly integrates patterns and colors, breaking the single image of traditional mesh and injecting new vitality into sports shoes. PART 01 The Footwear Industry Challenge However, in the production process of sports shoes, how to efficiently and accurately cut this same color mesh material has become a major problem for footwear industry. Traditionally, footwear industry usually use punching machines and dies for cutting, but this method is not only inefficient, but also increases the cost of labor, tooling and site management, limiting the flexibility of footwear industry to respond quickly to brand needs. (Traditional cutting of mesh material of...

In the vibrant and energetic city, more and more people choose running as a way to release pressure and enjoy life. From the quiet park trails in the morning to the illuminated riverside walkways at night, people who love sports are everywhere. However, for runners, a pair of suitable sneakers is crucial. It should not only meet the functional needs of running, but also be able to show fashion, trend and versatility. In recent years, the same-color mesh material has become a highlight in sneaker design with its unique visual effect and lightweight texture. Through the fine preparation process, this material cleverly integrates patterns and colors, breaking the single image of traditional mesh and injecting new vitality into sports shoes. PART 01 The Footwear Industry Challenge However, in the production process of sports shoes, how to efficiently and accurately cut this same color mesh material has become a major problem for footwear industry. Traditionally, footwear industry usually use punching machines and dies for cutting, but this method is not only inefficient, but also increases the cost of labor, tooling and site management, limiting the flexibility of footwear industry to respond quickly to brand needs. (Traditional cutting of mesh material of... -

Nov 25,2024

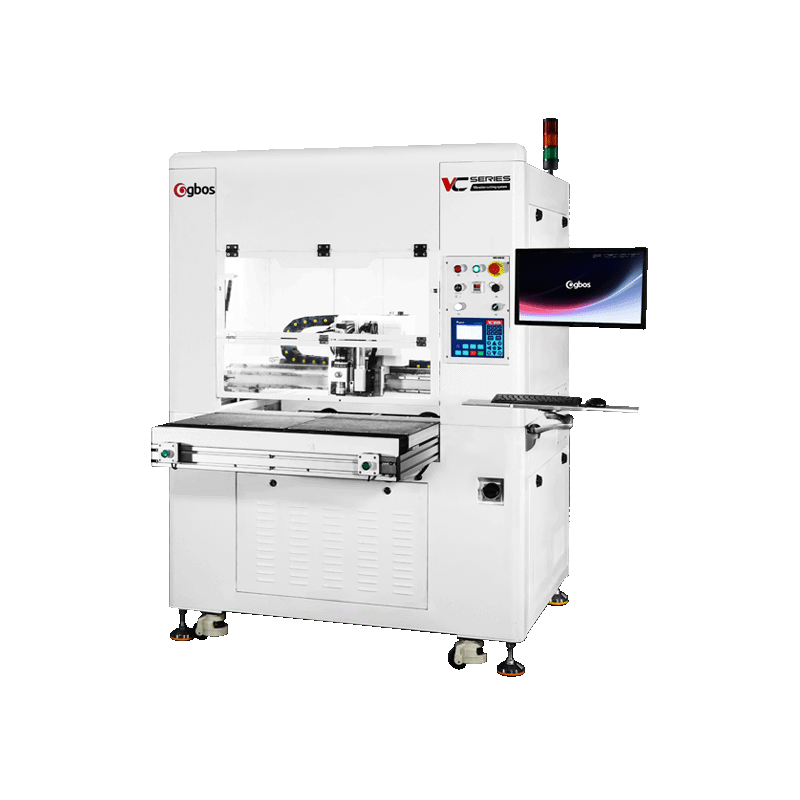

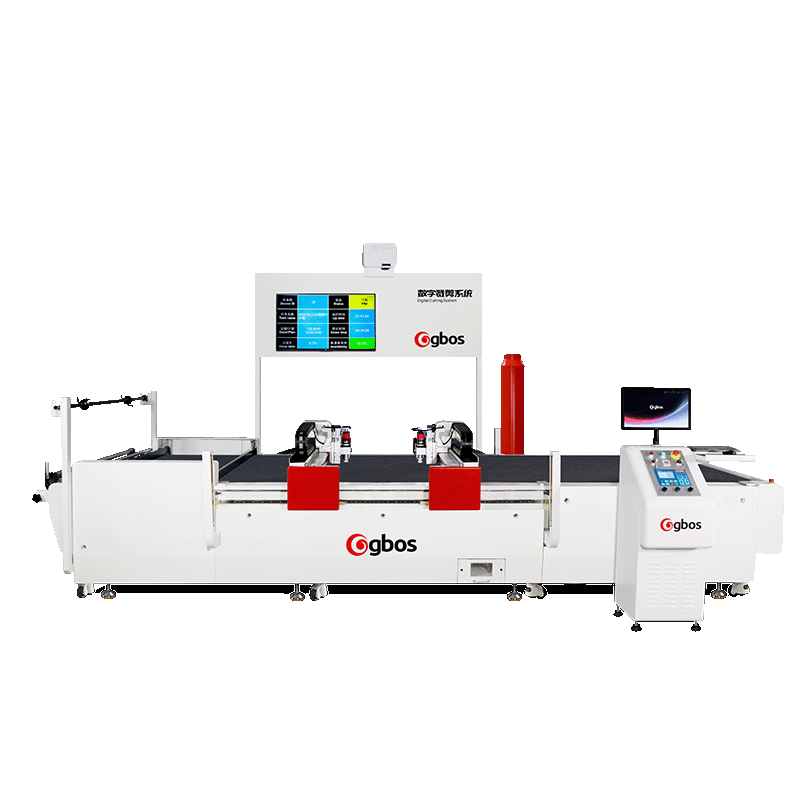

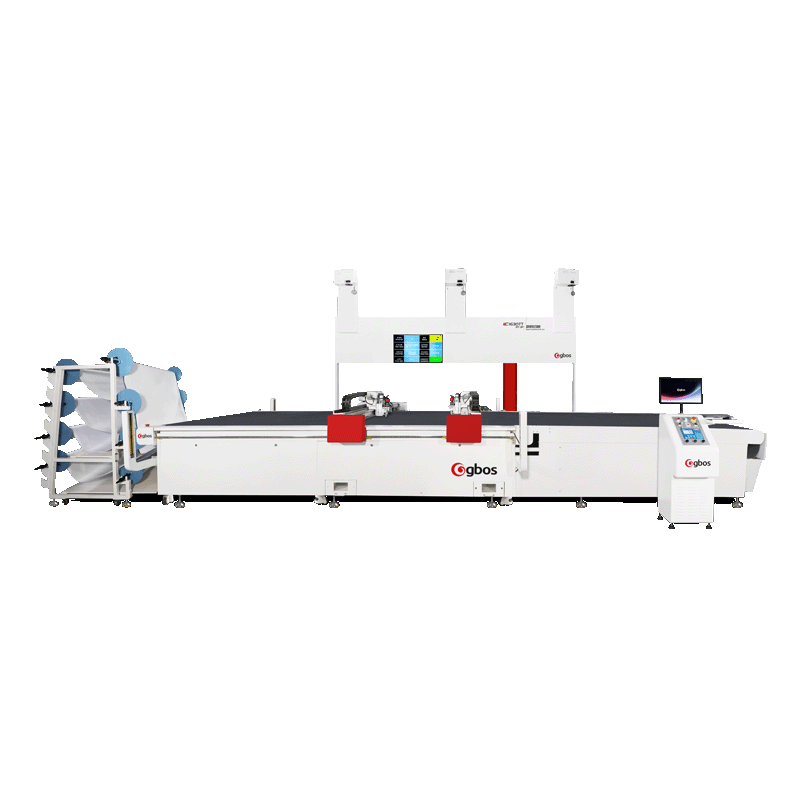

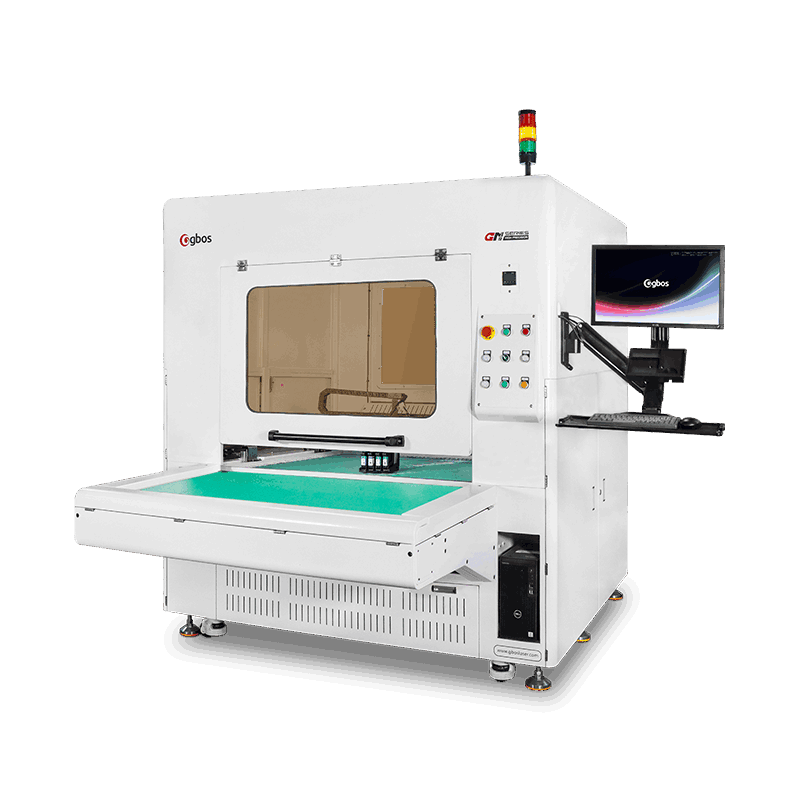

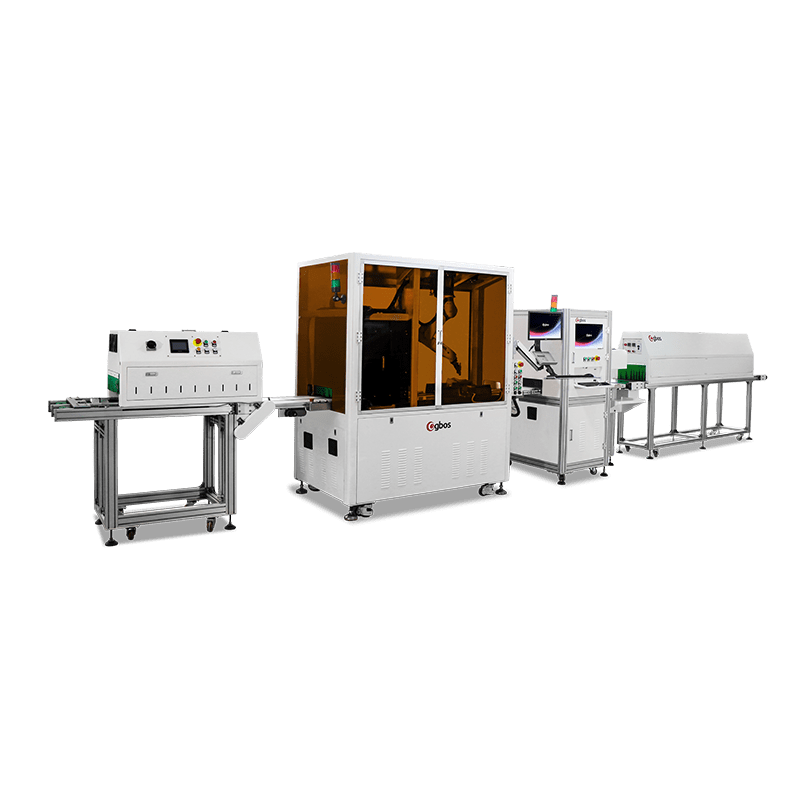

The market demand for labour protective equipment, as a solid guardian of workers’ safety, continues to climb. At the same time, the state’s increasing attention to production safety and the introduction of a series of related policies have put forward more stringent requirements for the production of labour protective equipment. Therefore, how to achieve efficient, accurate and environmentally friendly production has become a key issue for labour protective equipment manufacturers. 01 Innovative practices to promote high-quality development of the industry Aiming at this pain point in the labour protective equipment industry, GBOS launched the ‘Digital Cutting Center’ solution with his keen market insight and excellent technological innovation. The solution integrates ITS3-3012 AI intelligent leather nesting system, KC1660TT-3P digital cutting system and VC9-1616TT full-material multi-layer cutting system, which injects a strong intelligent power into the production of labour protective equipment. ITS3-3012 AI Intelligent Leather Nesting System: With powerful algorithms and learning capabilities, it is able to automatically optimise the leather nesting method, significantly improve material utilisation and effectively reduce leather loss. KC1660TT-3P Digital Cutting System: With precise cutting ability and excellent production efficiency, it ensures that the labour protection products can achieve double improvement in quality and production. VC9-1616TT Full Material...

The market demand for labour protective equipment, as a solid guardian of workers’ safety, continues to climb. At the same time, the state’s increasing attention to production safety and the introduction of a series of related policies have put forward more stringent requirements for the production of labour protective equipment. Therefore, how to achieve efficient, accurate and environmentally friendly production has become a key issue for labour protective equipment manufacturers. 01 Innovative practices to promote high-quality development of the industry Aiming at this pain point in the labour protective equipment industry, GBOS launched the ‘Digital Cutting Center’ solution with his keen market insight and excellent technological innovation. The solution integrates ITS3-3012 AI intelligent leather nesting system, KC1660TT-3P digital cutting system and VC9-1616TT full-material multi-layer cutting system, which injects a strong intelligent power into the production of labour protective equipment. ITS3-3012 AI Intelligent Leather Nesting System: With powerful algorithms and learning capabilities, it is able to automatically optimise the leather nesting method, significantly improve material utilisation and effectively reduce leather loss. KC1660TT-3P Digital Cutting System: With precise cutting ability and excellent production efficiency, it ensures that the labour protection products can achieve double improvement in quality and production. VC9-1616TT Full Material... -

Mar 30,2023

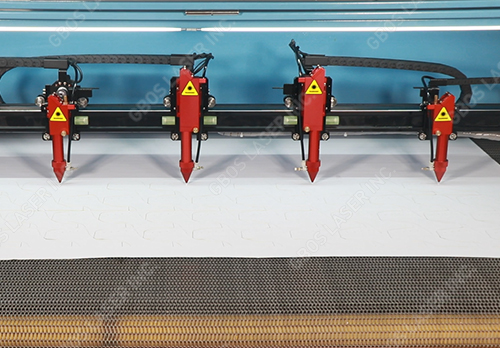

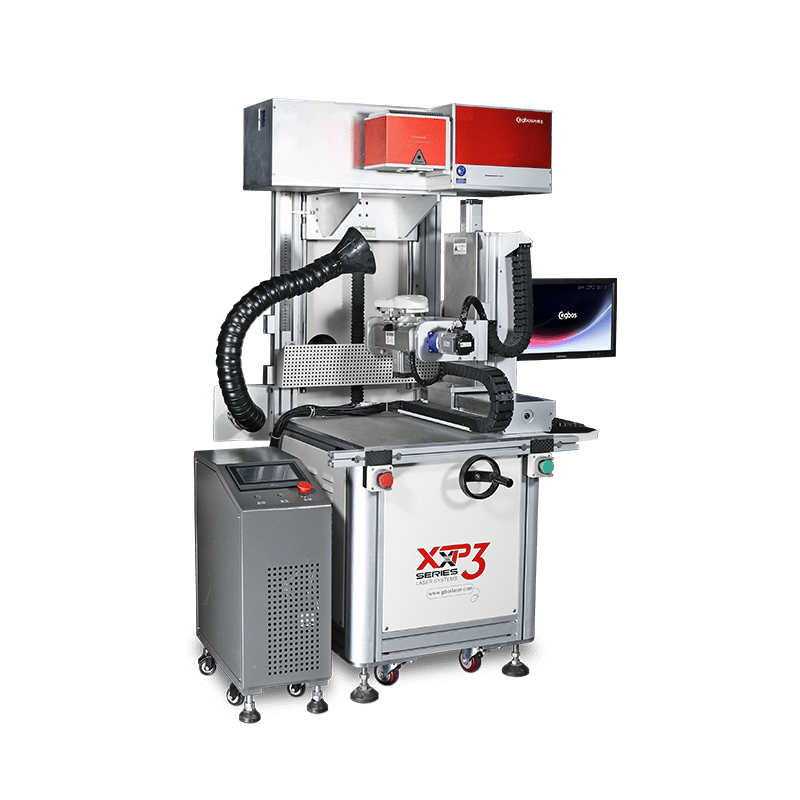

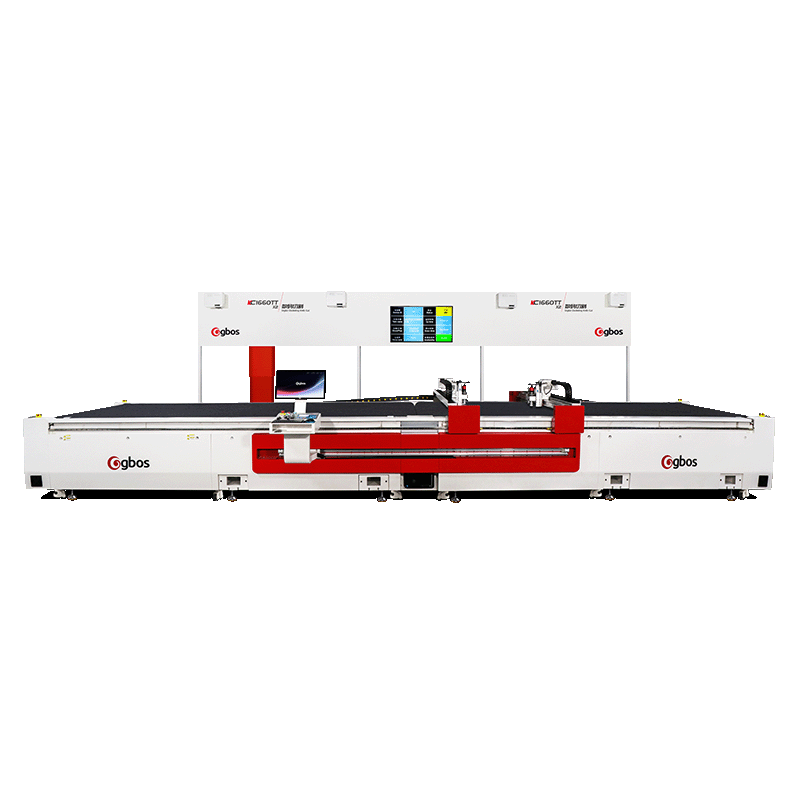

Whole four days, customers get passion all the time! Machines in this footwear exhibition(04.19-04.22): 1. VC9-1670, Double heads async digital knife cutting+punching machine for shoe accessories materials. Here, 6-layer TPU digital knife cutting. 2. V10-SCCD, VisionScan mesh upper laser cutting. 3. LA-GN1280TT-AT-SCCD, Double heads high speed auto line marking machine. 4. XXP3.2-180CCD, positioning hole process with laser marking. And, a set new machine in this exhibition! VC9-1616, Full shoe accessories materials digital knife cutting. Among these, VC9-1670, LA-GN1280TT-AT-SCCD, VC9-1616 have been sold in this exhibitions! Thanks for your support, it’s a successful exhibition! Looking forward to meeting you at The 30th Guangzhou International Footwear Exhibition soon, during May 31st to June 3rd.

Whole four days, customers get passion all the time! Machines in this footwear exhibition(04.19-04.22): 1. VC9-1670, Double heads async digital knife cutting+punching machine for shoe accessories materials. Here, 6-layer TPU digital knife cutting. 2. V10-SCCD, VisionScan mesh upper laser cutting. 3. LA-GN1280TT-AT-SCCD, Double heads high speed auto line marking machine. 4. XXP3.2-180CCD, positioning hole process with laser marking. And, a set new machine in this exhibition! VC9-1616, Full shoe accessories materials digital knife cutting. Among these, VC9-1670, LA-GN1280TT-AT-SCCD, VC9-1616 have been sold in this exhibitions! Thanks for your support, it’s a successful exhibition! Looking forward to meeting you at The 30th Guangzhou International Footwear Exhibition soon, during May 31st to June 3rd. -

Feb 08,2023

LongYun Group, the largest sports shoes manufacturer in east Sichuan province ,China, is a company that cooperates with famous brands such as Li Ning, Belle and Daphne, etc. In 2020, LongYun Group started the process of intelligence and digitalization comprehensively. IoT Bridge is introduced as the digital management support of intelligent manufacturing. IoT Bridge explores and solves the problem of how to use existing resources efficiently and how to advance production with intelligence. “When we talk to many entrepreneurs about IoT Bridge, they are confused: how does IoT Bridge apply to machines and how can it be grafted to their company?” “Why do we need IoT Bridge when ordinary automated machines can also drive production?” In fact, when introducing IoT Bridge, Longyun Group also started from business aspect and issues of transformation and upgrading, and after continuous adaptation and mapping, integration and adjustment, we found out a one-stop intelligent tailoring solution that is most suitable for our company. Why Introduce IOT Bridge In the early stage of development of the footwear industry, enterprises did not lack market and only needed to consider production issues. However, with the change of the intrinsic trend of the industry ecology, and face huge business...

LongYun Group, the largest sports shoes manufacturer in east Sichuan province ,China, is a company that cooperates with famous brands such as Li Ning, Belle and Daphne, etc. In 2020, LongYun Group started the process of intelligence and digitalization comprehensively. IoT Bridge is introduced as the digital management support of intelligent manufacturing. IoT Bridge explores and solves the problem of how to use existing resources efficiently and how to advance production with intelligence. “When we talk to many entrepreneurs about IoT Bridge, they are confused: how does IoT Bridge apply to machines and how can it be grafted to their company?” “Why do we need IoT Bridge when ordinary automated machines can also drive production?” In fact, when introducing IoT Bridge, Longyun Group also started from business aspect and issues of transformation and upgrading, and after continuous adaptation and mapping, integration and adjustment, we found out a one-stop intelligent tailoring solution that is most suitable for our company. Why Introduce IOT Bridge In the early stage of development of the footwear industry, enterprises did not lack market and only needed to consider production issues. However, with the change of the intrinsic trend of the industry ecology, and face huge business... -

Feb 08,2023

Current market situation of footwear industry Since the outbreak of Newcastle Pneumonia, the global economy has been hit hard, and the footwear industry is also facing a huge test. Although the footwear industry in China continues to grow, reports show that global footwear consumption will decrease by an average of 22.5% in 2021, with Europe down 27%, North America down 21% and Asia down 20%. The market operating environment of the footwear industry is extremely severe, and practitioners are facing tremendous pressure and challenges. Equipment optimization, poised for growth In the face of unstable market growth, companies face many challenges: On the one hand, the industry is aiming for internationalization and market globalization, and on the other hand, the traditional footwear industry is facing problems such as high labor costs and uneven quality of production. In addition, the ever-changing market demand requires companies to produce and deliver orders faster and more efficiently, putting higher demands on the shoe supply chain system. Companies must re-examine themselves to adapt to the changing demand conditions. For example, replacing manual labor or outdated machines with advanced equipment, thus increasing productivity and significantly improving productivity. A way to transform your production floor into a profit...

Current market situation of footwear industry Since the outbreak of Newcastle Pneumonia, the global economy has been hit hard, and the footwear industry is also facing a huge test. Although the footwear industry in China continues to grow, reports show that global footwear consumption will decrease by an average of 22.5% in 2021, with Europe down 27%, North America down 21% and Asia down 20%. The market operating environment of the footwear industry is extremely severe, and practitioners are facing tremendous pressure and challenges. Equipment optimization, poised for growth In the face of unstable market growth, companies face many challenges: On the one hand, the industry is aiming for internationalization and market globalization, and on the other hand, the traditional footwear industry is facing problems such as high labor costs and uneven quality of production. In addition, the ever-changing market demand requires companies to produce and deliver orders faster and more efficiently, putting higher demands on the shoe supply chain system. Companies must re-examine themselves to adapt to the changing demand conditions. For example, replacing manual labor or outdated machines with advanced equipment, thus increasing productivity and significantly improving productivity. A way to transform your production floor into a profit... -

Feb 08,2023

August 17th, a notice was published, Among them, to create a number of “small, fast, light and accurate” digital system solutions and to create 4,000-6,000 “small lighthouse” enterprises as digital transformation benchmark enterprises, is the notice pointed out in the manufacturing industry important guidance direction. Among them, the textile, clothing and leather products processing for the transformation of one of the pilot sub-sectors. The future of manufacturing: small, fast, light and accurate. The development of the manufacturing industry is the cornerstone of the development of the real economy. The development of the manufacturing industry in terms of miniaturisation, speed, lightness and precision is the top priority of the development of the digital economy, and the deep integration of the digital economy with the real economy is a favourable choice for achieving high-quality development. However, the traditional manufacturing model has brought many challenges to the digital development of the manufacturing industry, taking the processing of textile, garment and leather industries as an example: high labour costs, time-consuming processes and high energy consumption are among the many problems that arise. In order to actively respond to the national policy, as well as to effectively solve the traditional manufacturing industry pain points, GBOS...

August 17th, a notice was published, Among them, to create a number of “small, fast, light and accurate” digital system solutions and to create 4,000-6,000 “small lighthouse” enterprises as digital transformation benchmark enterprises, is the notice pointed out in the manufacturing industry important guidance direction. Among them, the textile, clothing and leather products processing for the transformation of one of the pilot sub-sectors. The future of manufacturing: small, fast, light and accurate. The development of the manufacturing industry is the cornerstone of the development of the real economy. The development of the manufacturing industry in terms of miniaturisation, speed, lightness and precision is the top priority of the development of the digital economy, and the deep integration of the digital economy with the real economy is a favourable choice for achieving high-quality development. However, the traditional manufacturing model has brought many challenges to the digital development of the manufacturing industry, taking the processing of textile, garment and leather industries as an example: high labour costs, time-consuming processes and high energy consumption are among the many problems that arise. In order to actively respond to the national policy, as well as to effectively solve the traditional manufacturing industry pain points, GBOS... -

Dec 21,2020

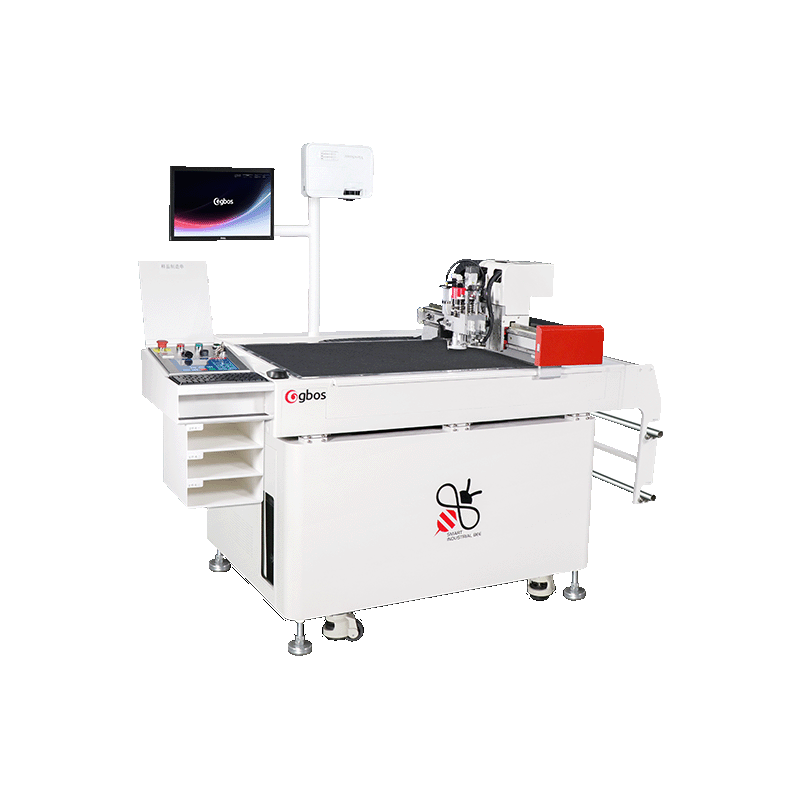

More than 200 footwear industry celebrities attend this conference. Before starting this conference, GBOS prepared a sports fashion show for our customers and friends. You can see some photos below! Then, GBOS CEO MR LIU WEN stated the current development status and future trend of our footwear & garmnet industry, which is bound to develop towards the small-volume, large-variety orders customized production mode, and the future processing machine is bound to develop towards the direction of artificial intelligence and digital automation. We always strive to create one stop cutting solution with laser & knife cutter! Also, we published a new machine “LA-GN1280TT-AT-SCCD ” in this conference, for 5G auto line marking machine, it’s an essential machine for footwear industry! And we define “faster than fast” for this machine! Next, GBOS offered you a solution for big date management in footwear industry— IoT Bridge Platform, the IoT Bridge Platform can achieve one machine control all production line. Can achieve real-time device management, digitalized lean production,, enter digital transformation… Machines in this conference Laser machine 1. XXP3.2-180-CCD, VisionScan high speed laser marking machine for positioning holes process. 2. GH1570F-AT, Four-head high speed laser cutting machine. 3. V10 SCCD, Dual-head async multifunction laser cutting system. Digital oscillating knife cutter 1. VC9-1670T/N, Multi-layer smart digital...

More than 200 footwear industry celebrities attend this conference. Before starting this conference, GBOS prepared a sports fashion show for our customers and friends. You can see some photos below! Then, GBOS CEO MR LIU WEN stated the current development status and future trend of our footwear & garmnet industry, which is bound to develop towards the small-volume, large-variety orders customized production mode, and the future processing machine is bound to develop towards the direction of artificial intelligence and digital automation. We always strive to create one stop cutting solution with laser & knife cutter! Also, we published a new machine “LA-GN1280TT-AT-SCCD ” in this conference, for 5G auto line marking machine, it’s an essential machine for footwear industry! And we define “faster than fast” for this machine! Next, GBOS offered you a solution for big date management in footwear industry— IoT Bridge Platform, the IoT Bridge Platform can achieve one machine control all production line. Can achieve real-time device management, digitalized lean production,, enter digital transformation… Machines in this conference Laser machine 1. XXP3.2-180-CCD, VisionScan high speed laser marking machine for positioning holes process. 2. GH1570F-AT, Four-head high speed laser cutting machine. 3. V10 SCCD, Dual-head async multifunction laser cutting system. Digital oscillating knife cutter 1. VC9-1670T/N, Multi-layer smart digital... -

Dec 17,2020

The new era of intelligent manufacturing has arrived. Are you ready for the upcoming 2021? Give yourself a chance to occupy the market firstly and create a digital production workshop that integrates intelligence, automation and informatization. A LIVE STREAM ON FACEBOOK! Time: Fir Dec. 18th, 2020 10:10, GMT +0800 Aim to”More than just fast, faster than fast, breakthrough the last mile of smart cutting,” Let’s explore the cutting, line marking, punching, glue spray solutions together! And explore the cutting application together! Show equipment VC9-1670T, Oscillating knife cutter, max cutting thickness: 18mm. GC850SCCD-P-EP, A machine for full-scene use, full-material use! Breakthrough the last mile of smart cutting. XXP3.2-180-CCD, High speed laser marking machine. V10SCCD, SCCD for contour extracting and cutting digital printing shoe upper. R3, Smart Spray glue systems for shoe. LA-GN1280TT-SCCD-AT, Double head async 5G smart auto marking line machine. ITS2, Smart nesting system. VC9-1612, Small order, sample model. Provide you fully a set of automatic solutions, and help your shoe factory enter Industry 4.0 before 2021! Help you enter smart die-less cutting; Inputting pattern, cutting, feeding, collecting, calculating all in one; Customized and more!

The new era of intelligent manufacturing has arrived. Are you ready for the upcoming 2021? Give yourself a chance to occupy the market firstly and create a digital production workshop that integrates intelligence, automation and informatization. A LIVE STREAM ON FACEBOOK! Time: Fir Dec. 18th, 2020 10:10, GMT +0800 Aim to”More than just fast, faster than fast, breakthrough the last mile of smart cutting,” Let’s explore the cutting, line marking, punching, glue spray solutions together! And explore the cutting application together! Show equipment VC9-1670T, Oscillating knife cutter, max cutting thickness: 18mm. GC850SCCD-P-EP, A machine for full-scene use, full-material use! Breakthrough the last mile of smart cutting. XXP3.2-180-CCD, High speed laser marking machine. V10SCCD, SCCD for contour extracting and cutting digital printing shoe upper. R3, Smart Spray glue systems for shoe. LA-GN1280TT-SCCD-AT, Double head async 5G smart auto marking line machine. ITS2, Smart nesting system. VC9-1612, Small order, sample model. Provide you fully a set of automatic solutions, and help your shoe factory enter Industry 4.0 before 2021! Help you enter smart die-less cutting; Inputting pattern, cutting, feeding, collecting, calculating all in one; Customized and more! -

Nov 13,2020

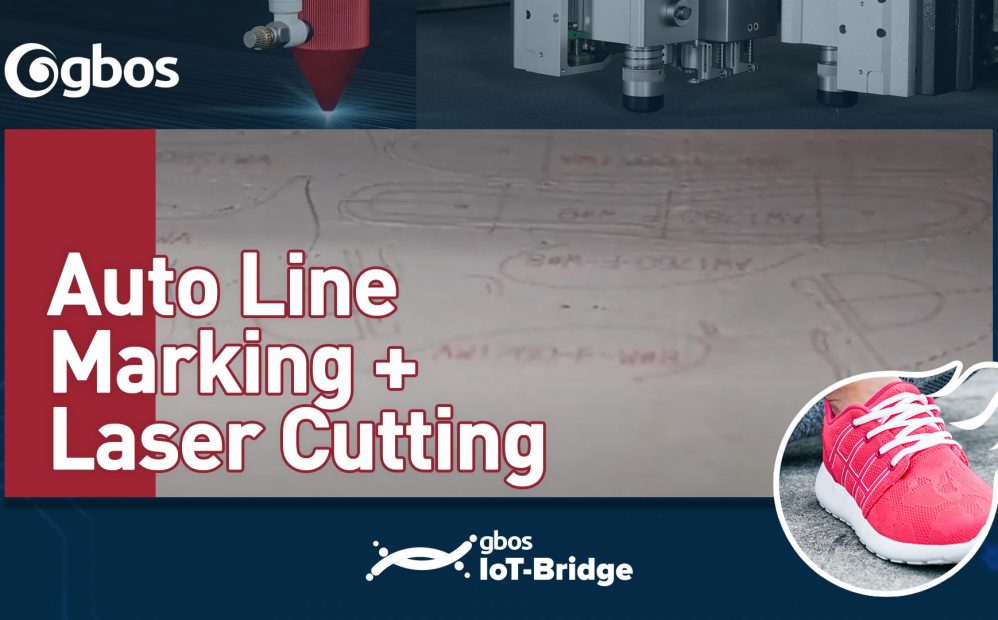

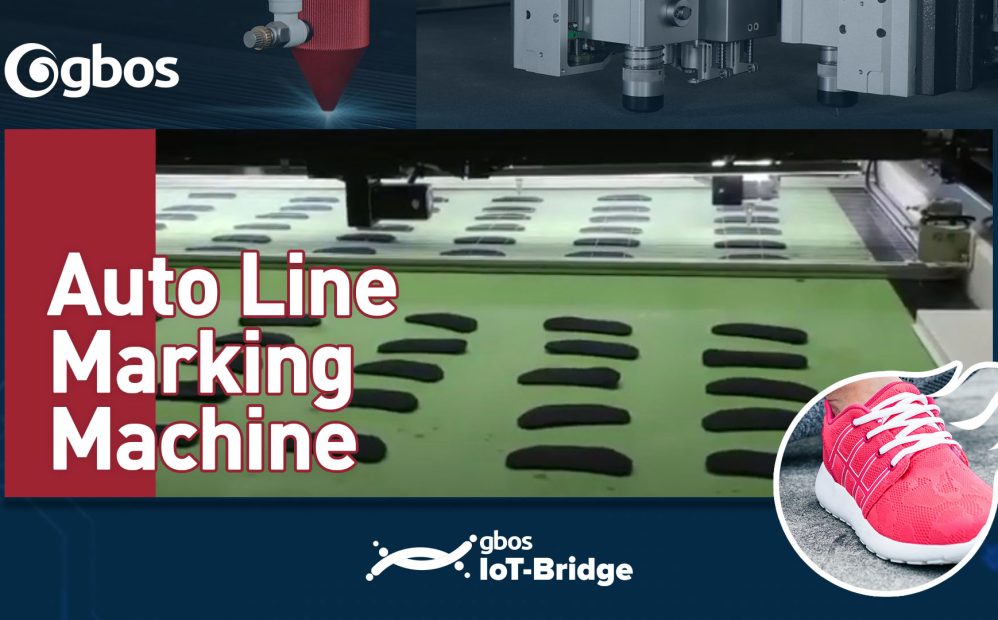

GBOS“Me”improve team continuous improve and develop according to market and customers’ demand. Develop a new auto marking line machine LA-GN1280TT-AT-SCCD specially for you~ Automatic device replace traditional silk screen printing line, as you known, traditional techniques use pens and screens to mark l ines. Their labor and consumable costs are high. But work efficiency and product quality are low. At the same time, it will cause environmental pollution during use. Therefore, more and more factories are looking for machines to replace manual production. GBOS Smart auto marking line machine has higher precision, double-head async cutting, higher speed. Widely used in footwear, garment, bags factories. You can see this follow samples. Machine functions: Intergrated loading materials, auto marking line, drying system, collect materials. Any cut parts, no need fixed placement position. Can make sure materials flat in working tabel, and the effects are more better. Contact us and discover more advantages!

GBOS“Me”improve team continuous improve and develop according to market and customers’ demand. Develop a new auto marking line machine LA-GN1280TT-AT-SCCD specially for you~ Automatic device replace traditional silk screen printing line, as you known, traditional techniques use pens and screens to mark l ines. Their labor and consumable costs are high. But work efficiency and product quality are low. At the same time, it will cause environmental pollution during use. Therefore, more and more factories are looking for machines to replace manual production. GBOS Smart auto marking line machine has higher precision, double-head async cutting, higher speed. Widely used in footwear, garment, bags factories. You can see this follow samples. Machine functions: Intergrated loading materials, auto marking line, drying system, collect materials. Any cut parts, no need fixed placement position. Can make sure materials flat in working tabel, and the effects are more better. Contact us and discover more advantages! -

Jun 07,2016

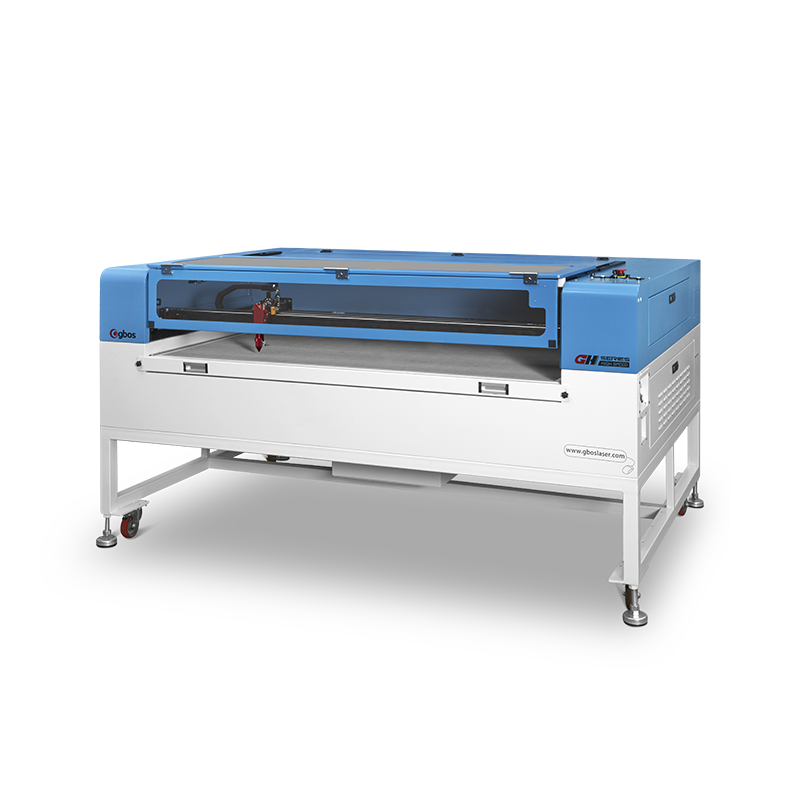

![[New Product Launch] GBOS V8plus Double Head Asynchronous Intelligent Feeding System Global New Product Launch [New Product Launch] GBOS V8plus Double Head Asynchronous Intelligent Feeding System Global New Product Launch](https://www.gboslaser.com/wp-content/uploads/2023/03/2023051616024027dbb-457x270.png) “Smart double match, super material saving, fast feeding, automatic counting…” On January 12, 2016, Gbos Laser held the global new product launch for V8plus double head asynchronous intelligent feeder, which was themed on”born for shoe factory, intelligent tailoring”. The released new product is the 8th generation of “V” series multifunctional automatic feeding laser-cutting machine independently researched and developed by GBOS,with “Smart Tailoring” as the biggest highlight. Its superior functionsare mainly revealedin three aspects. First, crossed layout on the same pattern, fast cutting in different horizontal lines. Secondly, double head automatic double match fast cutting on positive and negative patterns; Thirdly, double head asynchronous, fast cutting for multiple parts patterns. As the eighth generation of enhanced flagship model, PLUS combines all excellent functions ofthe previous seven generations, with 35% faster speed, 10% material saving,and more superior and practical performance. As the survival environment is worsening for the traditional shoe companies, the industry is calling for intelligent production. This launch of V8PLUS is providing an improvement solution for the labor, efficiency, and cost issues intraditional enterprise transformation.

“Smart double match, super material saving, fast feeding, automatic counting…” On January 12, 2016, Gbos Laser held the global new product launch for V8plus double head asynchronous intelligent feeder, which was themed on”born for shoe factory, intelligent tailoring”. The released new product is the 8th generation of “V” series multifunctional automatic feeding laser-cutting machine independently researched and developed by GBOS,with “Smart Tailoring” as the biggest highlight. Its superior functionsare mainly revealedin three aspects. First, crossed layout on the same pattern, fast cutting in different horizontal lines. Secondly, double head automatic double match fast cutting on positive and negative patterns; Thirdly, double head asynchronous, fast cutting for multiple parts patterns. As the eighth generation of enhanced flagship model, PLUS combines all excellent functions ofthe previous seven generations, with 35% faster speed, 10% material saving,and more superior and practical performance. As the survival environment is worsening for the traditional shoe companies, the industry is calling for intelligent production. This launch of V8PLUS is providing an improvement solution for the labor, efficiency, and cost issues intraditional enterprise transformation.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: