-

Industry Trends/Customer Challenges

Industry Trends/Customer ChallengesFirst, global textile consumption is constantly upgrading, with denim clothing and fabrics trending towards high quality, strong functionality, and a laser-textured style.

As environmental protection awareness grows globally, eco-friendly clothing consumption has become deeply ingrained in public consciousness. Traditional water-based washing is labor-intensive and has inflicted severe environmental and ecological damage. In contrast, laser washing significantly cuts costs, aligns with the new environmental protection theme, and integrates scientific, eco-friendly, and innovative ideas while boosting productivity.

Born into a digitally connected era, today's youth prioritize clothing style and personal expression. They form distinct groups through consumption and possess a unique discourse system. Fashion trends now embrace a wider array of styles, including bleached, flash-colored, segmented denim, fancy yarn designs, and garments blending woven and knitted denim. There's even a trend towards pairing denim with smart wearables, creating innovative combinations.

-

GBOS Advantages of GBOS Solutions

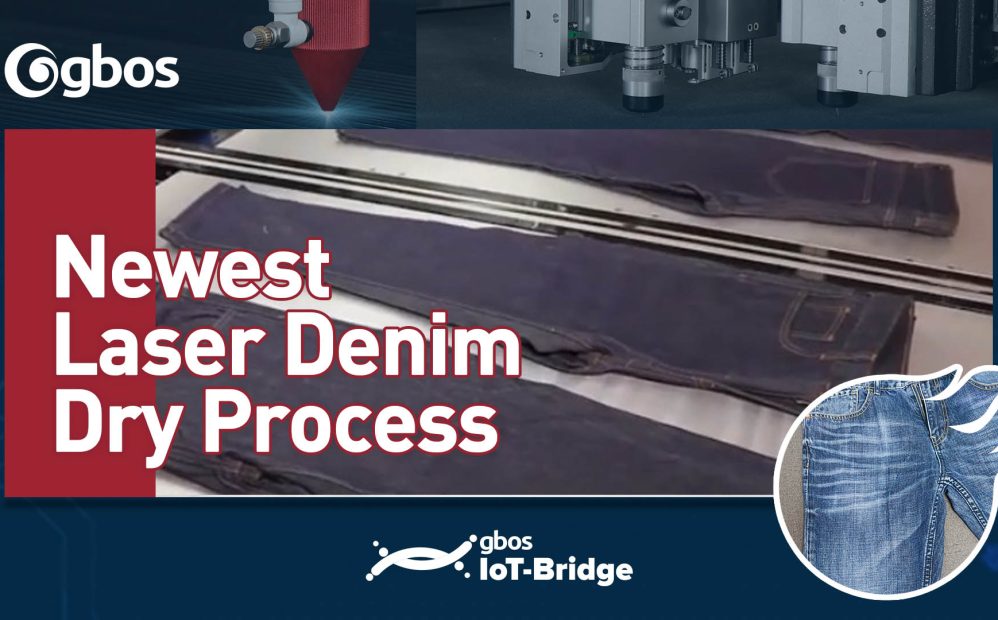

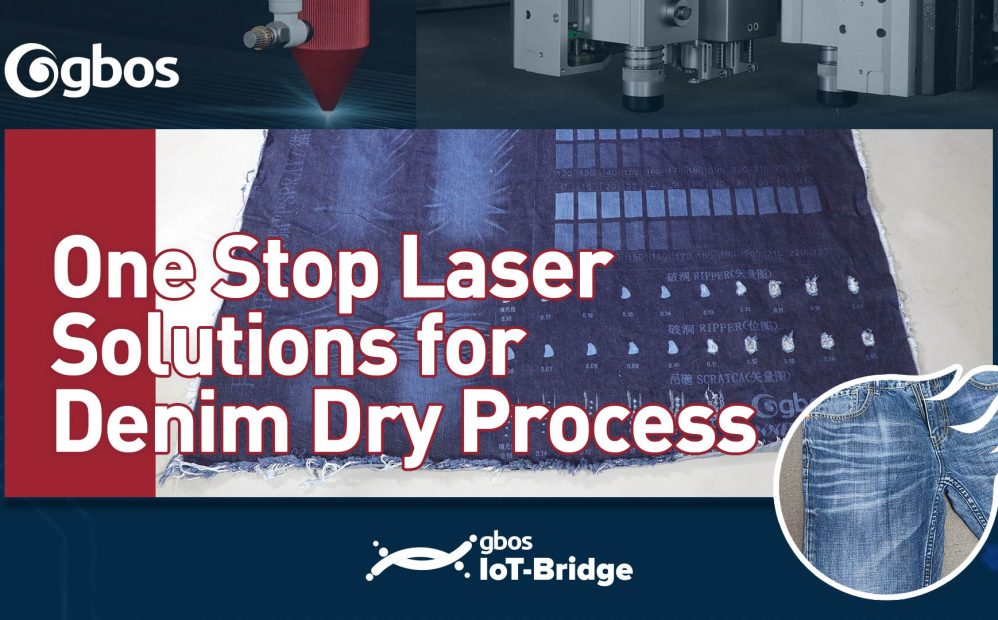

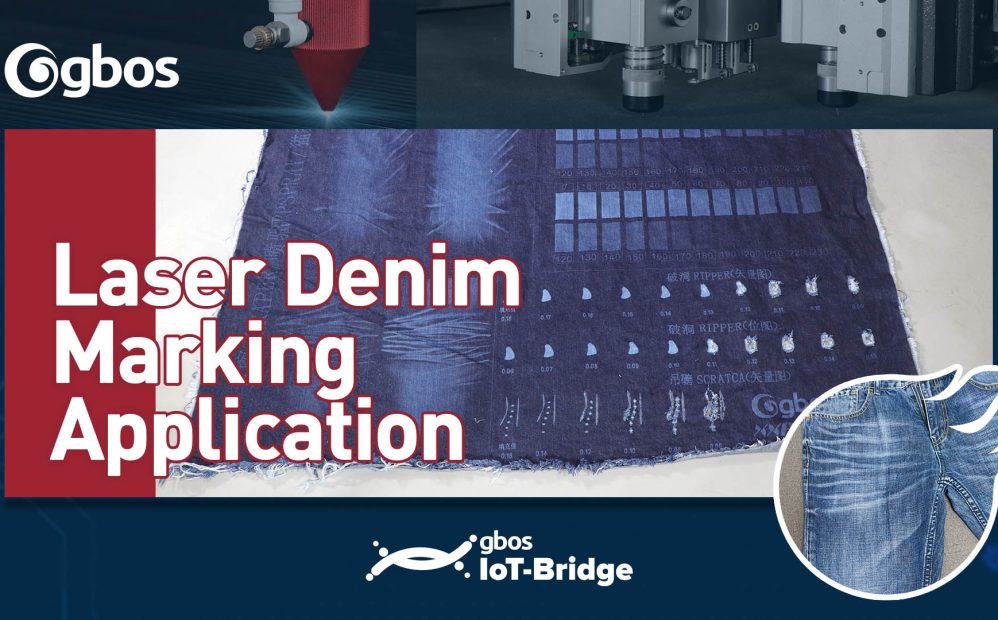

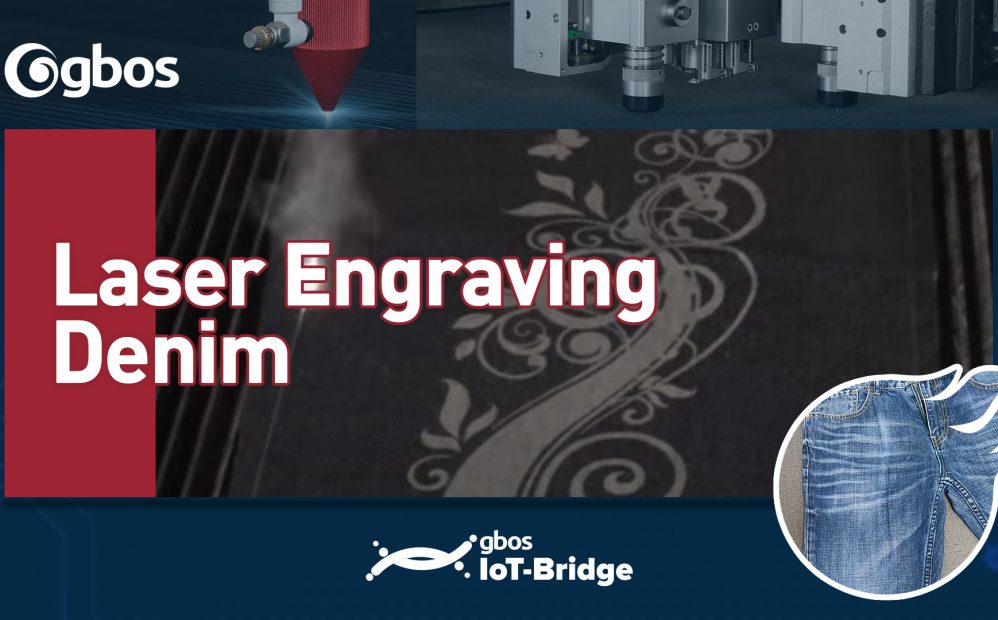

GBOS Advantages of GBOS SolutionsOne Solution For Laser Washing Process: Laser Ripping, Laser Whiskers, PP Spray Simulation, Laser Grinding, All-over Laser Marking all in one.

Green solutions: With less water, less energy, less emission, one standard for production, and easy operation, multi models to satisfy different request.

No More Complicated Skills. Just Say A Few Words, Or A Single Image, And The System Creates The Design For You.

- Laser Denim Dry Process(Laser Ripping)

- Laser Denim Dry Process(Laser Grinding)

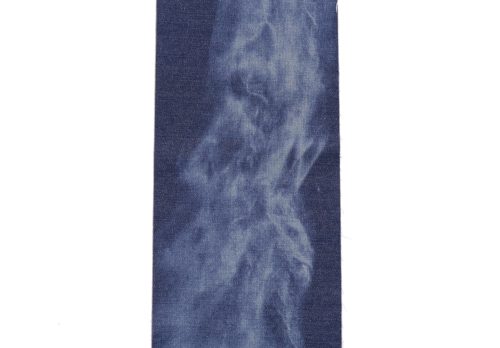

- Laser Denim Dry Process(PP Spray Simulation)

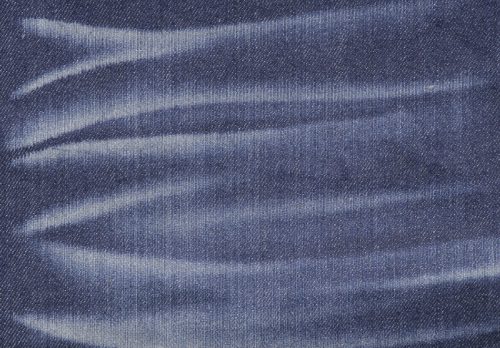

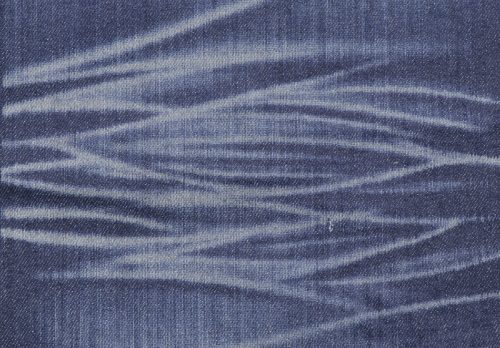

- Laser Denim Dry Process(Laser Whiskers)

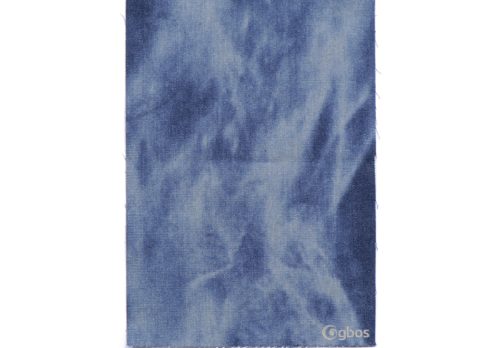

- Laser Denim Dry Process(All-over Laser Marking)

-

Dec 25,2024

In this ever-changing world of fashion, there are always some single product as a witness of time, through the baptism of time but more and more classic – denim, is this eternal chapter of the immortal pen. The key to evaluating whether a pair of jeans is washed or aged is the natural flow of flavor. Unnatural washing traces, like a poor imitation, people can feel the cheap artifice at a glance; while the real natural washing of the old, the color from light to dark, the transition is natural, every wear and tear, color and even holes in the patches, as if telling the story of the wearer, and the traces of time coincide with each other. 01 windsock in the Cowboy Industry In recent years, the trend of the denim industry has been characterized by both diversification and sustainability. on the one hand, designers are constantly exploring new possibilities for denim fabrics, from color and cut to functionality, and every innovation has injected new vitality into denim apparel. On the other hand, as consumers become more aware of environmental protection and sustainable fashion becomes an irreversible trend, the denim industry is also looking for more environmentally friendly production...

In this ever-changing world of fashion, there are always some single product as a witness of time, through the baptism of time but more and more classic – denim, is this eternal chapter of the immortal pen. The key to evaluating whether a pair of jeans is washed or aged is the natural flow of flavor. Unnatural washing traces, like a poor imitation, people can feel the cheap artifice at a glance; while the real natural washing of the old, the color from light to dark, the transition is natural, every wear and tear, color and even holes in the patches, as if telling the story of the wearer, and the traces of time coincide with each other. 01 windsock in the Cowboy Industry In recent years, the trend of the denim industry has been characterized by both diversification and sustainability. on the one hand, designers are constantly exploring new possibilities for denim fabrics, from color and cut to functionality, and every innovation has injected new vitality into denim apparel. On the other hand, as consumers become more aware of environmental protection and sustainable fashion becomes an irreversible trend, the denim industry is also looking for more environmentally friendly production... -

Jan 05,2021

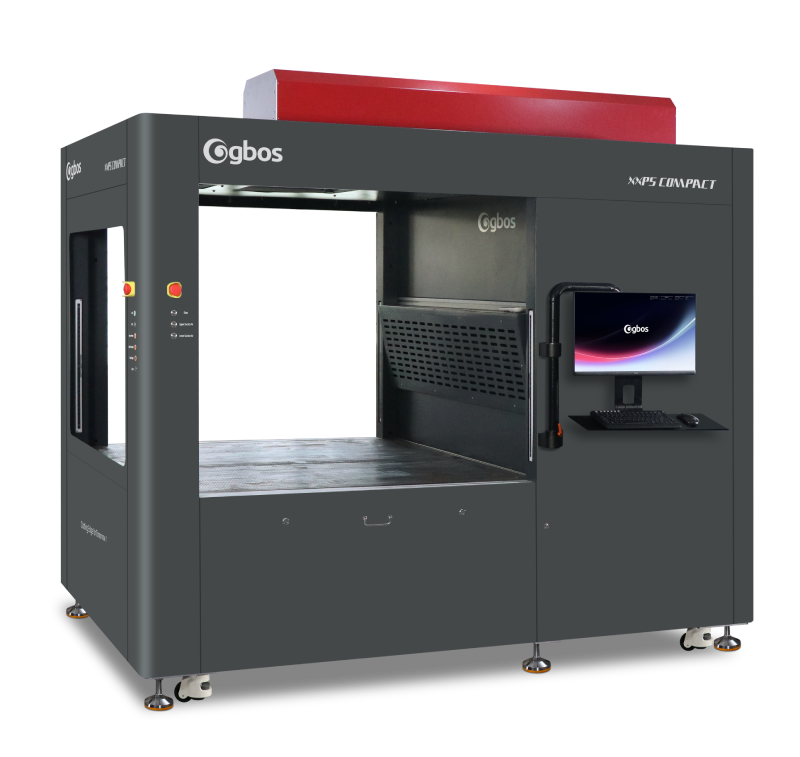

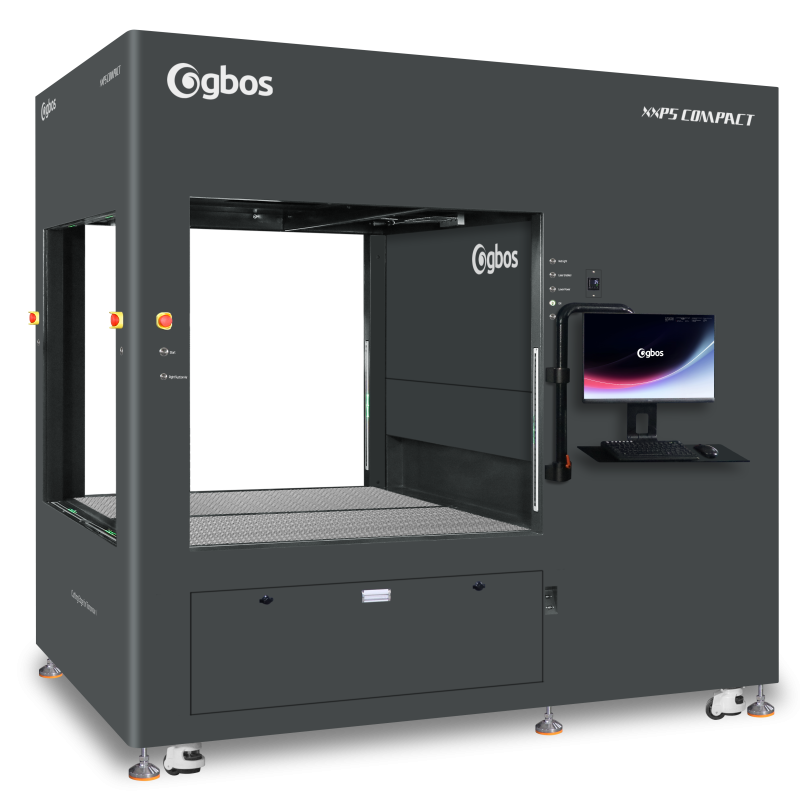

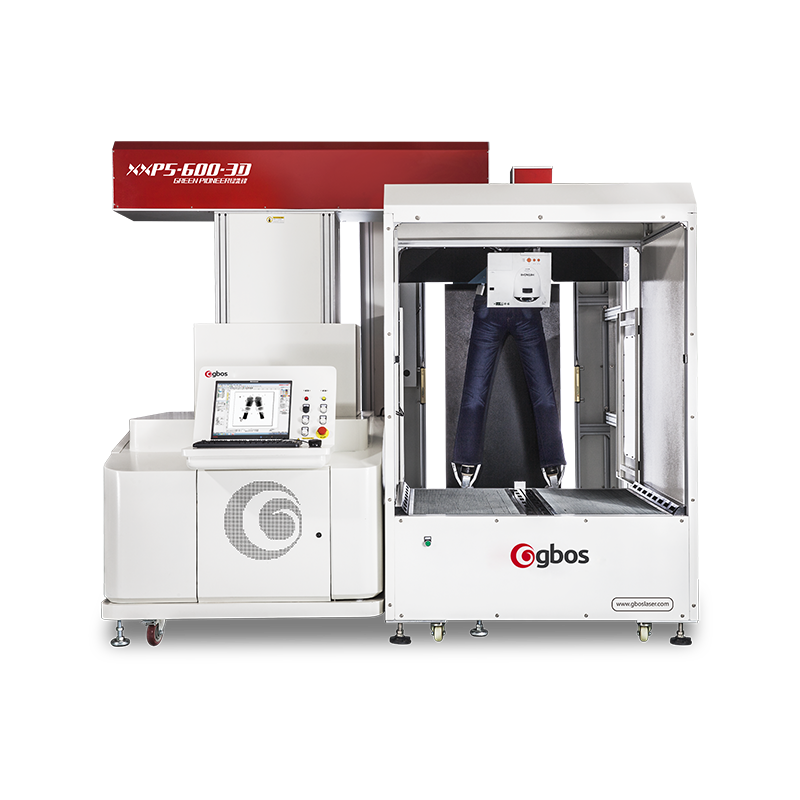

Dec. 12 2020 GMT +0800(CST), we held a conference about laser denim dry process. Now let’s review this conference! Conference process: 1. Technological advantage explanation 2. New machine world premiere 3. Live display of all range models At the begining, a living show for you! Then, introduce new environment about GBOS! Next, our customers enter “GBOS School” for an communication! In this communication, the president of Rofin of Great China Region, Mr.Ding. has a speech for us! He shared about the technology from Rofin using which isused in Denim industry. It’s worth looking forward the words he has said! Share one stop laser denim dry process solutions with you! Machines in this conference 1. XXP3-180, For children’s jeans and DIY partial process for adult’s jeans in the area of 600*600 mm. 2. XXP4, For batch orders and sample room. 3. XXP5-600, For Large batch orders production line. 4. XXP5-600-3D, Save labours customization products. 5. XXP5-600-AW, New product publish! Fully a set of laser denim dry process solutions! This machines all for laser denim dry process! For PP spray, cat whisker, full marking, ripper, grinding, etc! See some videos now!

Dec. 12 2020 GMT +0800(CST), we held a conference about laser denim dry process. Now let’s review this conference! Conference process: 1. Technological advantage explanation 2. New machine world premiere 3. Live display of all range models At the begining, a living show for you! Then, introduce new environment about GBOS! Next, our customers enter “GBOS School” for an communication! In this communication, the president of Rofin of Great China Region, Mr.Ding. has a speech for us! He shared about the technology from Rofin using which isused in Denim industry. It’s worth looking forward the words he has said! Share one stop laser denim dry process solutions with you! Machines in this conference 1. XXP3-180, For children’s jeans and DIY partial process for adult’s jeans in the area of 600*600 mm. 2. XXP4, For batch orders and sample room. 3. XXP5-600, For Large batch orders production line. 4. XXP5-600-3D, Save labours customization products. 5. XXP5-600-AW, New product publish! Fully a set of laser denim dry process solutions! This machines all for laser denim dry process! For PP spray, cat whisker, full marking, ripper, grinding, etc! See some videos now! -

Dec 04,2020

Hey, New 2021 is approaching. Are you ready for your new plan? Newly upgraded “S-Denim 6.0” is waiting for you! Dec. 12th, Supply “S-denim 6.0” software for you. Comprehensive process, and also new machine world premiere. We are all looking forward to your coming, we have a Facebook/YouTube live show for you! Let’s explore more possibilities together that day! We perpare this kind of artcraft solution on denim/new machine for one year, go through numerous failure, GBOS staffs work night and day overtime, only for this kind of machine. We just want to bring you the best! And can meet the market demands. You know, the process of making a pair of jeans is time-honored— it’s also time-cosuming; Whisker, Monkey wash, Grinding, and other effects on denim, a laser machine can treat a pair of jeans in a very short time and with extraordinary accuracy. A further advantage is certainly represented by the outstanding customizations that are now possible while once were not, due to the traditional systems. We move towards tradition, but more intelligent than traditional! So on Dec. 12th, looking forward to our talk together! New environment, new machine, more artcraft are waiting for you!

Hey, New 2021 is approaching. Are you ready for your new plan? Newly upgraded “S-Denim 6.0” is waiting for you! Dec. 12th, Supply “S-denim 6.0” software for you. Comprehensive process, and also new machine world premiere. We are all looking forward to your coming, we have a Facebook/YouTube live show for you! Let’s explore more possibilities together that day! We perpare this kind of artcraft solution on denim/new machine for one year, go through numerous failure, GBOS staffs work night and day overtime, only for this kind of machine. We just want to bring you the best! And can meet the market demands. You know, the process of making a pair of jeans is time-honored— it’s also time-cosuming; Whisker, Monkey wash, Grinding, and other effects on denim, a laser machine can treat a pair of jeans in a very short time and with extraordinary accuracy. A further advantage is certainly represented by the outstanding customizations that are now possible while once were not, due to the traditional systems. We move towards tradition, but more intelligent than traditional! So on Dec. 12th, looking forward to our talk together! New environment, new machine, more artcraft are waiting for you! -

Dec 31,2015

2015 autumn CHIC, GBOS Laser introduced Green Pioneer 2D intelligent denim washing system. Just like the Green Pioneer 3D, they are the advanced devices used to substitute the traditional washing technological methods. There is more than 95% of similarity between them and the manual water washing. According to Mr. Liu Wu, the deputy general manager of GBOS Laser, the GBOS Laser devices are very popular in Bangladesh, Turkey, and Iran; however, the situation is not so optimistic in domestic market. He further maintained that there are two reasons behind the situation according to the market survey. On one hand, the cost to introduce laser washing devices are huge, and on the other hand, the environment protection awareness is not sufficient. Through a few demonstrations in the exhibition, the journalists found that people in the industry shows an increasingly strong interest in the laser washing devices. In this exhibition, GBOS Laser attracts streams of visitors through its glossy brand that claimed to be “intelligent, fashionable, environmental-friendly and customized”. Mr. Liu said that currently the customized service is hot. They could create personalized marks, names, or design patterns and monkey washings according to different requirements of the customers. Talking about the...

2015 autumn CHIC, GBOS Laser introduced Green Pioneer 2D intelligent denim washing system. Just like the Green Pioneer 3D, they are the advanced devices used to substitute the traditional washing technological methods. There is more than 95% of similarity between them and the manual water washing. According to Mr. Liu Wu, the deputy general manager of GBOS Laser, the GBOS Laser devices are very popular in Bangladesh, Turkey, and Iran; however, the situation is not so optimistic in domestic market. He further maintained that there are two reasons behind the situation according to the market survey. On one hand, the cost to introduce laser washing devices are huge, and on the other hand, the environment protection awareness is not sufficient. Through a few demonstrations in the exhibition, the journalists found that people in the industry shows an increasingly strong interest in the laser washing devices. In this exhibition, GBOS Laser attracts streams of visitors through its glossy brand that claimed to be “intelligent, fashionable, environmental-friendly and customized”. Mr. Liu said that currently the customized service is hot. They could create personalized marks, names, or design patterns and monkey washings according to different requirements of the customers. Talking about the... -

Jun 03,2015

On May 6, 2015, the Green Pioneer 3D Environmental Laser Jeans Washing System Press Conference was held in GBOS factory. There were over 80 people attending the conference, which included representatives from jeans manufactures in Pearl River Delta, Jiangsu, Zhejiang, and Fujian such as Zengzhi, Conshing, Everstar, Ligao, etc., people form Guangzhou Sewing Equipment Chamber of Commerce, Junan Textile Chamber of Commerce, Xintang Chamber of Commerce and other associations as well as major media such as the central, provincial and municipal television stations. With the theme of “make the water clean together with GBOS”, the conference was held in the Jeans Washing Center of the factory, no high-end, classy, high-grade magnificence or dazzling light. The simple and plain Jeans Washing Center equipped only with a projector, dozens of chairs and several big equipments just showed GBOS Laser’s culture of practicality and dedication. Making the water clean was an environmental dream, for which the GBOS Laser-Green Pioneer 3D Environmental Laser Jeans Washing System Press Conference was held. According to a report from Times in USA, an American renowned jeans company has made an assessment for the resources of one type of jeans it produced and the result is astonishing: jeans are...

On May 6, 2015, the Green Pioneer 3D Environmental Laser Jeans Washing System Press Conference was held in GBOS factory. There were over 80 people attending the conference, which included representatives from jeans manufactures in Pearl River Delta, Jiangsu, Zhejiang, and Fujian such as Zengzhi, Conshing, Everstar, Ligao, etc., people form Guangzhou Sewing Equipment Chamber of Commerce, Junan Textile Chamber of Commerce, Xintang Chamber of Commerce and other associations as well as major media such as the central, provincial and municipal television stations. With the theme of “make the water clean together with GBOS”, the conference was held in the Jeans Washing Center of the factory, no high-end, classy, high-grade magnificence or dazzling light. The simple and plain Jeans Washing Center equipped only with a projector, dozens of chairs and several big equipments just showed GBOS Laser’s culture of practicality and dedication. Making the water clean was an environmental dream, for which the GBOS Laser-Green Pioneer 3D Environmental Laser Jeans Washing System Press Conference was held. According to a report from Times in USA, an American renowned jeans company has made an assessment for the resources of one type of jeans it produced and the result is astonishing: jeans are... -

Sep 20,2014

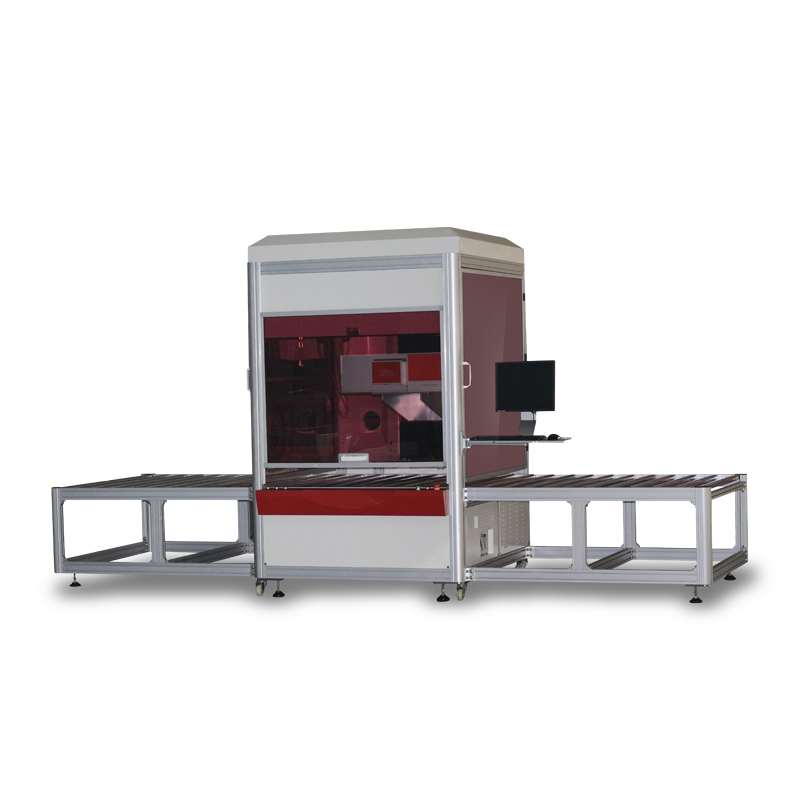

Today we are meeting global warming, traditional denim washing process directly cause the destruction of the ecological environment resources, the big pollution for water, air, soil, and plants accordingly. More serious is the harmful gas full of the working environments, will directly caused the workers meet the cancel risk sharply increased. To solve these problems, laser washing systems become the only choice for this industry. In the past Chinese market, these equipments have been occupied by Europe and America, so we go deep into the world’s largest denim factory, learnt about the entire process of washing denim, many times communicated with staff and factory owners to understand the real needs of the customers, after two years of research and development, we overcome all sorts of technical problems, and successfully developed a superior equipment than other similar brands of denim washing equipments in all respects: XXP5 Denim Laser Washing System. XXP5 is truly 100% environmentally friendly, no need to add any auxiliary chemical substances on denim& jeans, even don’t need the water purification process. This processed directly to finished product for delivery. XXP5 also has high speed and high efficient working performance, its processing speed is at least 15% higher than similar equipments....

Today we are meeting global warming, traditional denim washing process directly cause the destruction of the ecological environment resources, the big pollution for water, air, soil, and plants accordingly. More serious is the harmful gas full of the working environments, will directly caused the workers meet the cancel risk sharply increased. To solve these problems, laser washing systems become the only choice for this industry. In the past Chinese market, these equipments have been occupied by Europe and America, so we go deep into the world’s largest denim factory, learnt about the entire process of washing denim, many times communicated with staff and factory owners to understand the real needs of the customers, after two years of research and development, we overcome all sorts of technical problems, and successfully developed a superior equipment than other similar brands of denim washing equipments in all respects: XXP5 Denim Laser Washing System. XXP5 is truly 100% environmentally friendly, no need to add any auxiliary chemical substances on denim& jeans, even don’t need the water purification process. This processed directly to finished product for delivery. XXP5 also has high speed and high efficient working performance, its processing speed is at least 15% higher than similar equipments....

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: