-

Industry Trends/Customer Challenges

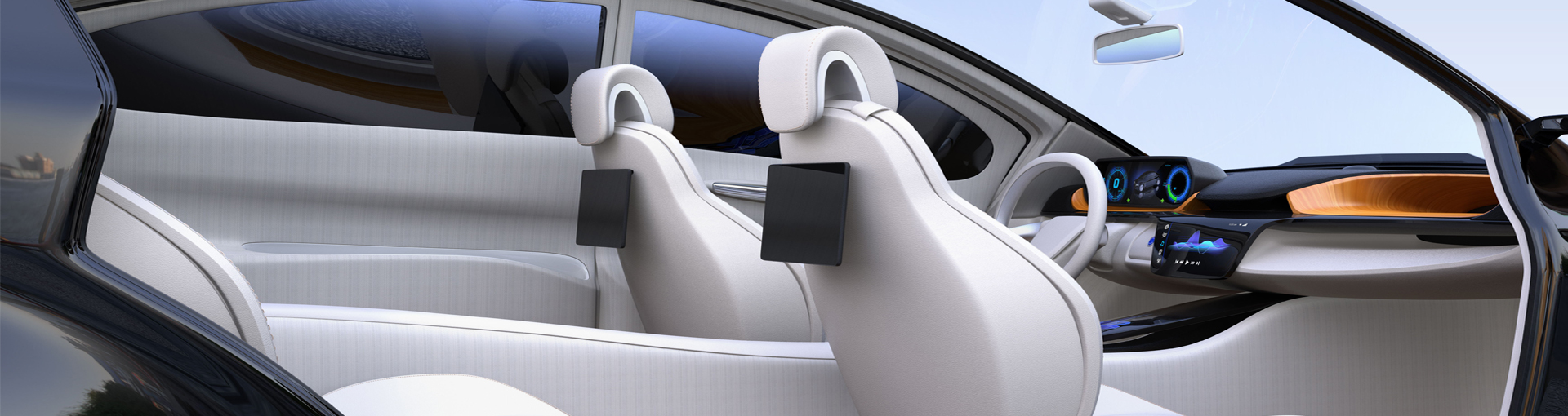

Industry Trends/Customer ChallengesThe automotive interior industry involves a wide variety and large quantity of materials. From cutting large-format materials like seats and floor mats to precision processes such as marking function buttons and engraving interior patterns, manufacturers face tough challenges, including high labor costs, low precision, poor quality, and low production efficiency.

The rapid rise of new energy vehicles has dramatically increased the demand for high-quality, aesthetically pleasing automotive interiors. Comfortable interiors are now an essential factor in consumers' vehicle choices.

In response to these market changes, automotive interior manufacturers and brands urgently need to overcome inefficient production practices. They seek multifunctional, all-material, high-precision, and labor-saving digital machinery to meet the new personalized consumer demands.

-

Advantages of GBOS Solutions

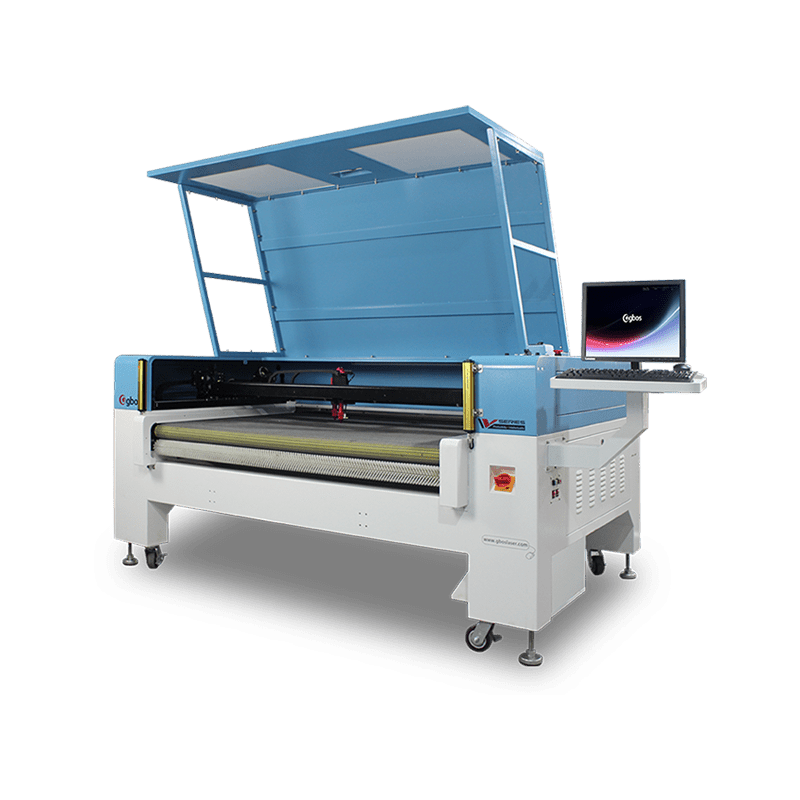

Advantages of GBOS SolutionsCustomized Solutions: Tailored cutting solutions for various flexible automotive interior materials like leather, foam, and composite materials, covering multiple processes such as cutting, marking, engraving, and punching to achieve optimal production outcomes.

Fully Automated Process: Highly automated procedures integrated with a self-developed software system reduce labor costs while enabling quick order response, meeting the needs of personalized and customized production.

Digitalized Production: An IoT system with data visualization enables real-time monitoring of production data and equipment status, maximizing efficiency for digital production management and control.

- Automotive Interior (Flexible Material) Cutting Solutions

- Automotive Exterior Materials Laser Cutting Solutions

- Shaped Materials Laser Cutting & Trimming Solution

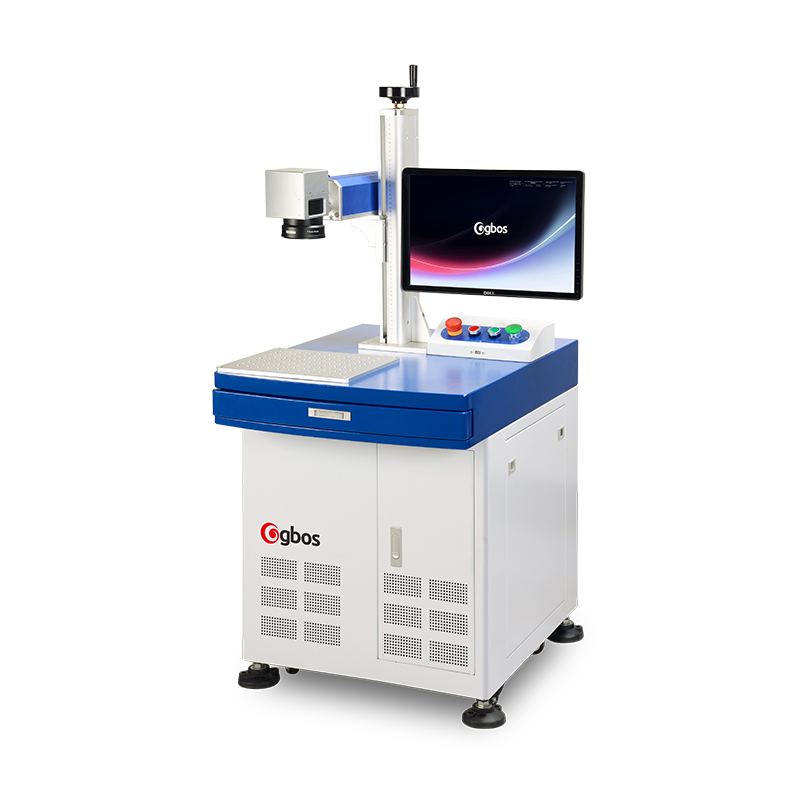

- Automotive Interior Laser Marking Solutions

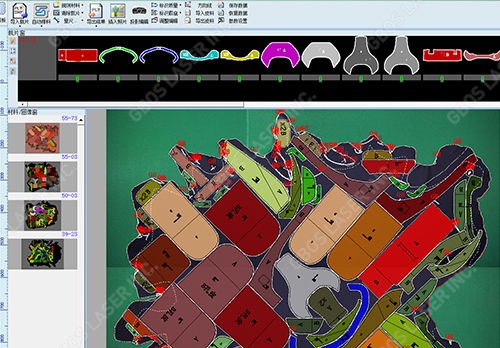

- Automotive Interior Leather Nesting Sys

-

ITS5 AI Leather Nesting SystemLarge Format Intelligent AI Nesting System for Overall LeatherMore Details

ITS5 AI Leather Nesting SystemLarge Format Intelligent AI Nesting System for Overall LeatherMore Details -

XXP3-250High Speed Galvo Birthday Greeting Card Wedding card Laser Engraving Cutting Marking MachineMore Details

XXP3-250High Speed Galvo Birthday Greeting Card Wedding card Laser Engraving Cutting Marking MachineMore Details -

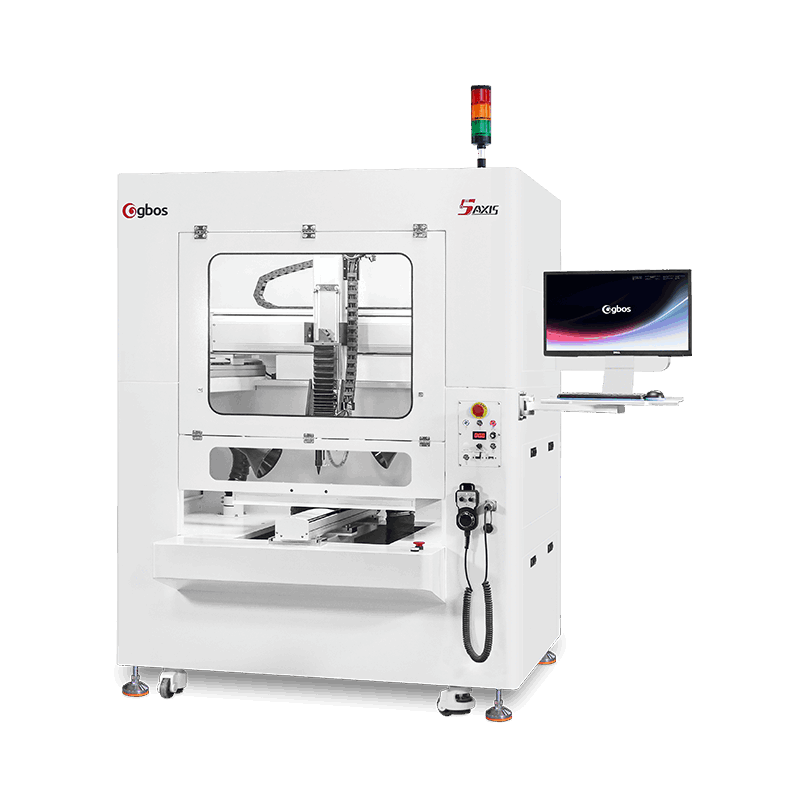

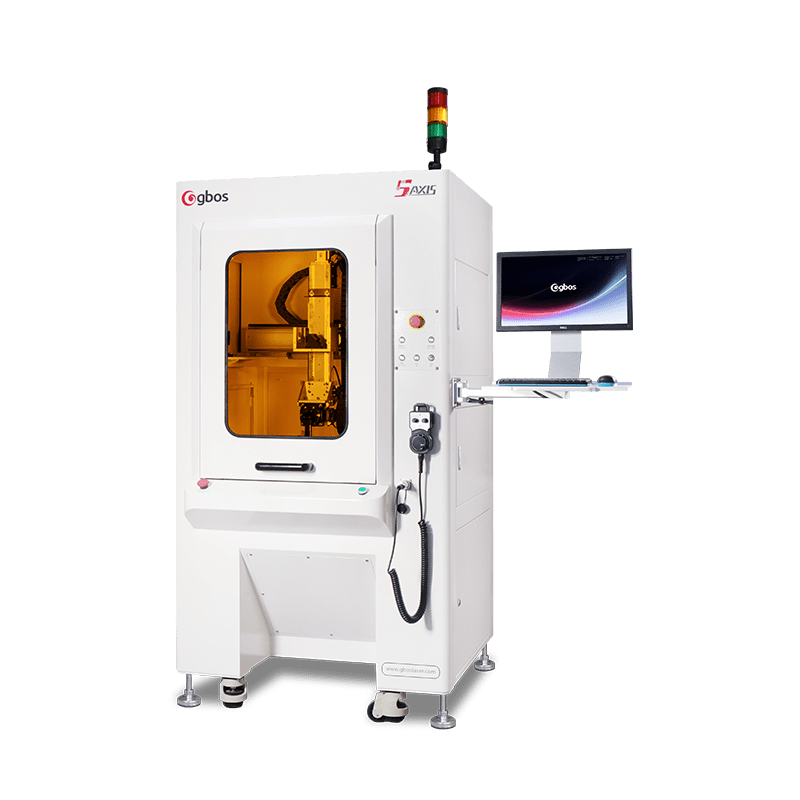

GN502-3D-EPGN502-3D-EP Five-axis Intelligent CO2 Laser Cutting Machine With Dual Working Tables.More Details

GN502-3D-EPGN502-3D-EP Five-axis Intelligent CO2 Laser Cutting Machine With Dual Working Tables.More Details -

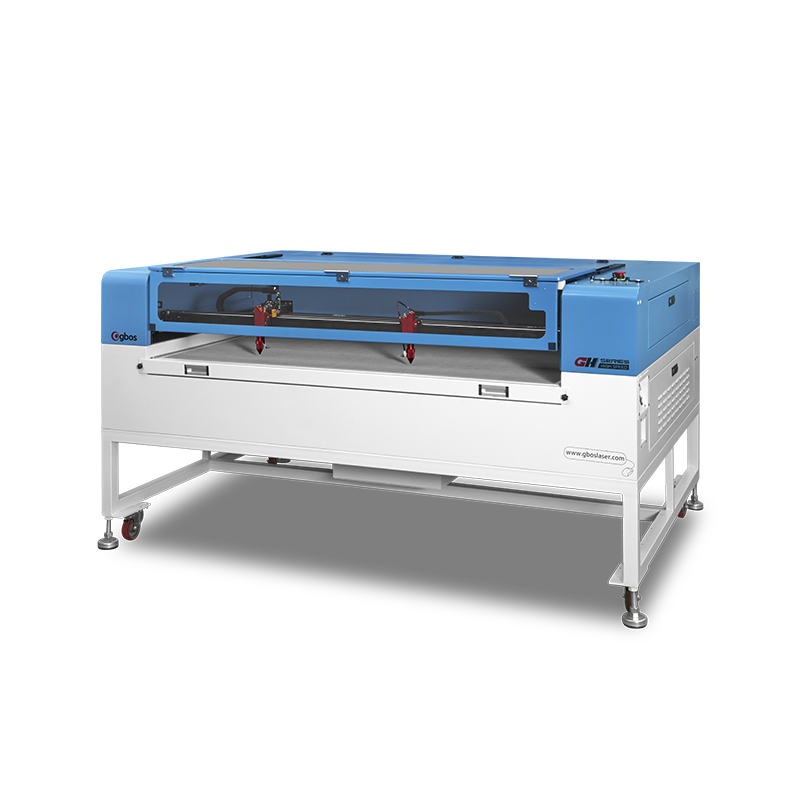

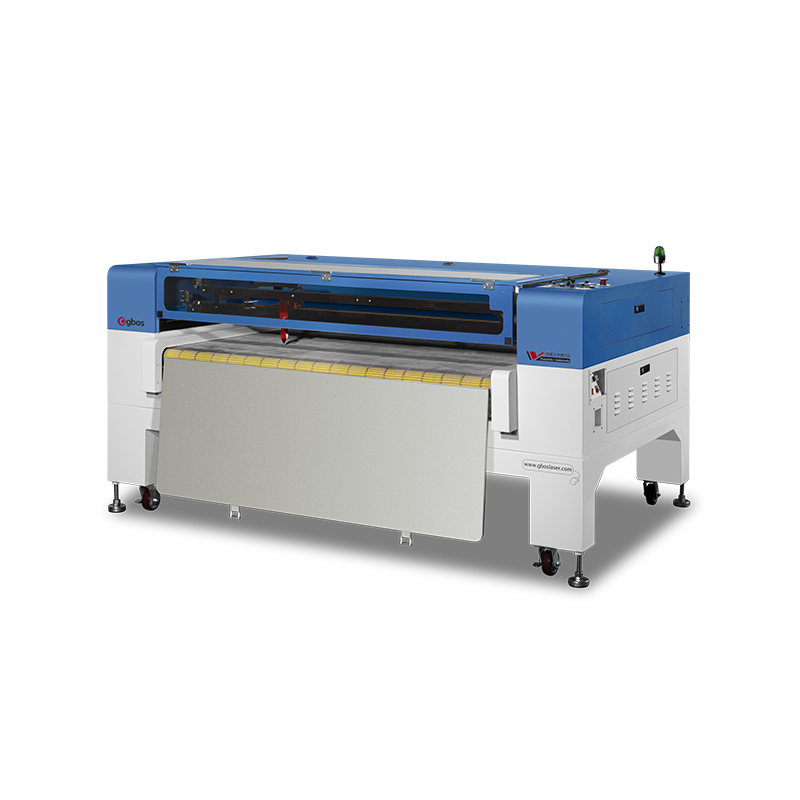

GH1812T-AT-SCCDTwo heads Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

GH1812T-AT-SCCDTwo heads Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

-

Oct 23,2024

The development of China’s automotive industry has transformed from weak beginnings to remarkable prosperity, marking a significant historical chapter. As the market shifts from rapid expansion to stable competition, the automotive sector stands at a new historical juncture, facing fresh opportunities for globalization. This is not just a challenge but a golden period for Chinese automotive brands to showcase their strength on the global stage and strategize anew. 01 Innovative Manufacturing in Automotive Interiors: Key to Enhancing Market Competitiveness Among various manufacturing stages, the design and production of automotive interiors are crucial. They impact vehicle aesthetics, functionality, consumer experience, and market competitiveness. With increasing demands for intelligent, high-quality, and timely delivery from brands and manufacturers, interior manufacturers must adopt effective strategies, innovating and optimizing processes to meet these high standards. 02 Growth Strategies for Interior Manufacturers To maintain a competitive edge, interior manufacturers should implement strategies such as increasing R&D investment, promoting technological innovation, enhancing manufacturing processes, ensuring product quality and consistency, and utilizing advanced digital production management systems to improve decision-making and responsiveness to market changes. GBOS excels in implementing these strategies, offering one-stop smart cutting and innovative process solutions for automotive interiors. This includes: Leather Layout and Cutting...

The development of China’s automotive industry has transformed from weak beginnings to remarkable prosperity, marking a significant historical chapter. As the market shifts from rapid expansion to stable competition, the automotive sector stands at a new historical juncture, facing fresh opportunities for globalization. This is not just a challenge but a golden period for Chinese automotive brands to showcase their strength on the global stage and strategize anew. 01 Innovative Manufacturing in Automotive Interiors: Key to Enhancing Market Competitiveness Among various manufacturing stages, the design and production of automotive interiors are crucial. They impact vehicle aesthetics, functionality, consumer experience, and market competitiveness. With increasing demands for intelligent, high-quality, and timely delivery from brands and manufacturers, interior manufacturers must adopt effective strategies, innovating and optimizing processes to meet these high standards. 02 Growth Strategies for Interior Manufacturers To maintain a competitive edge, interior manufacturers should implement strategies such as increasing R&D investment, promoting technological innovation, enhancing manufacturing processes, ensuring product quality and consistency, and utilizing advanced digital production management systems to improve decision-making and responsiveness to market changes. GBOS excels in implementing these strategies, offering one-stop smart cutting and innovative process solutions for automotive interiors. This includes: Leather Layout and Cutting... -

Feb 08,2023

Comfortable, Luxurious Car Seats are the Preferred Choice. Consumers are no longer limited to the aesthetics of their cars, but are paying more and more attention to the aesthetics, comfort and personalisation of the interior when purchasing. As an important part of the car’s interior, consumers are particularly demanding about car seats. For example, some of the existing ventilated seats are not well ventilated due to irregular breathable holes, so car owners will choose a more breathable car seat to replace the original seat to maintain a comfortable and breathable feeling; or replace it with a set of tailor-made seats, which can not only enhance the car’s class, highlight the unique personality, but also add a sense of comfort. As a result, the comfort of car seats and innovative manufacturing processes have become a key concern for many manufacturers of automotive interiors. If punching is continuously performed with automated machines, when different hole diameters are required, customized punching needles need to be replaced and the process is unique and only applicable to the punching process. GBOS, as a service provider offering innovative process solution, has developed the XXP3-180 intelligent high-speed laser...

Comfortable, Luxurious Car Seats are the Preferred Choice. Consumers are no longer limited to the aesthetics of their cars, but are paying more and more attention to the aesthetics, comfort and personalisation of the interior when purchasing. As an important part of the car’s interior, consumers are particularly demanding about car seats. For example, some of the existing ventilated seats are not well ventilated due to irregular breathable holes, so car owners will choose a more breathable car seat to replace the original seat to maintain a comfortable and breathable feeling; or replace it with a set of tailor-made seats, which can not only enhance the car’s class, highlight the unique personality, but also add a sense of comfort. As a result, the comfort of car seats and innovative manufacturing processes have become a key concern for many manufacturers of automotive interiors. If punching is continuously performed with automated machines, when different hole diameters are required, customized punching needles need to be replaced and the process is unique and only applicable to the punching process. GBOS, as a service provider offering innovative process solution, has developed the XXP3-180 intelligent high-speed laser...

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: