Stock Code: 870145

GNM1081CCD

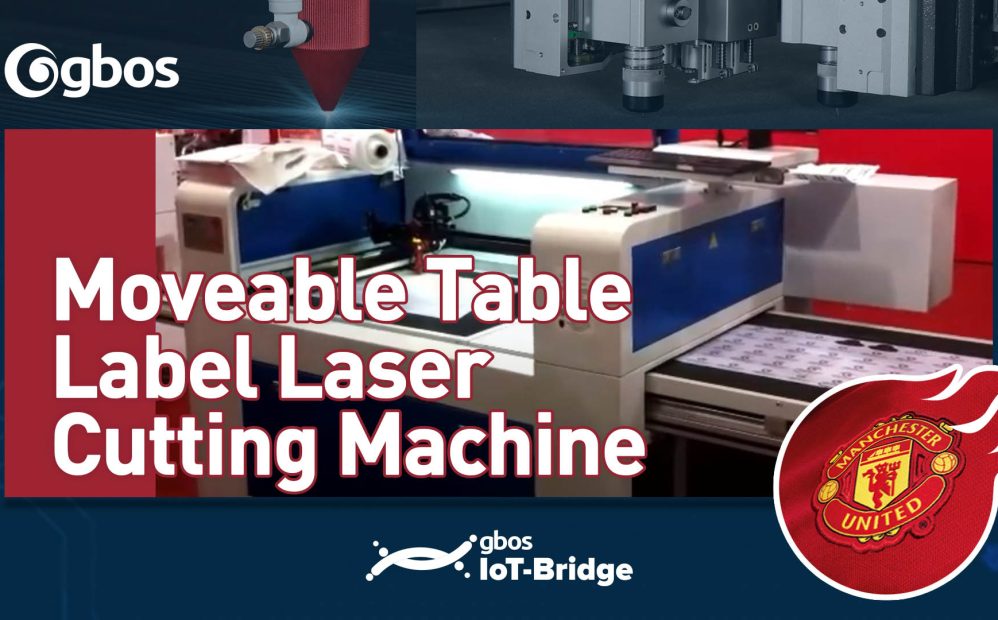

Double Capacity Sliding Working Table Laser Cutting Machine

Double-station operation, one person can operate 5 machines, to meet complex process requirements: deformed label cutting, label coding, and more application.

Achieving edge cutting effect.

Automatically identitying defect.

Full auto feeding device(optional).

Dual-platform free switching(optional).

Cutting with no burn and no yellow edge.

Sliding working table, double capacity effiency.

Multi pattern, any angle positioning and cutting.

| Working area | Gross power | Laser power | Power supply | Dimension | Overall weight | System compatible format |

|---|---|---|---|---|---|---|

| 850*600mm | 2000W | 90W | 220V/10A, 50HZ/60HZ | 3000×1090×1100MM | 380KG | WIN10/11,PLT, DXF |

Functions & Modules

-

Enabling asynchronous cutting of different shapes, improving production efficiency and reducing production time.More Details

Enabling asynchronous cutting of different shapes, improving production efficiency and reducing production time.More Details -

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details -

One for laser working, one for collecting, greatly improve efficiency.More Details

One for laser working, one for collecting, greatly improve efficiency.More Details -

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: