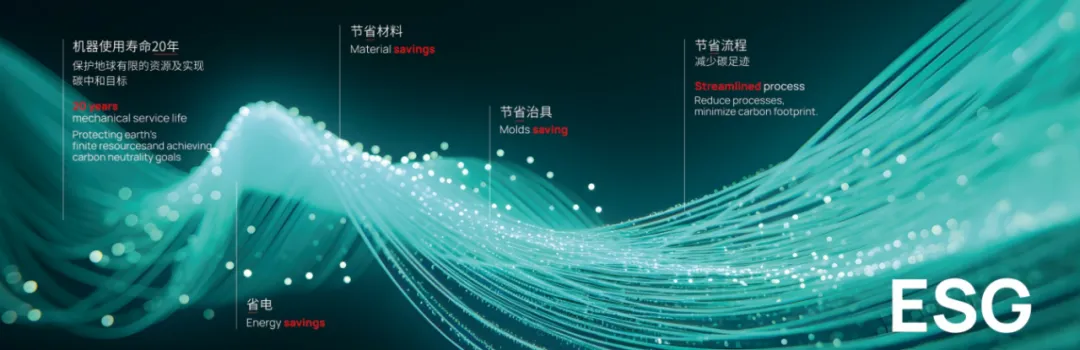

In the pursuit of Precision Smart Manufacturing 4.0, GBOS is not only committed to technological innovation and industrial upgrading, but also deeply rooted in the concept of ESG (Environmental, Social and Governance), and has become a leader in promoting the development of manufacturing industry in the direction of green and sustainable.

We understand that in the face of increasingly severe environmental challenges and social responsibility, the road to transformation in the manufacturing industry must revolve around ESG to ensure that while improving productivity, we can achieve a comprehensive improvement in environmental protection, social responsibility and corporate governance.

01 Environment: Green Leadership for a Low-Carbon Future

In the flexible manufacturing industry, GBOS is gradually leading a green revolution by virtue of its profound technological accumulation and innovative spirit. We understand that reducing material waste and energy consumption is the key to achieving sustainable development.

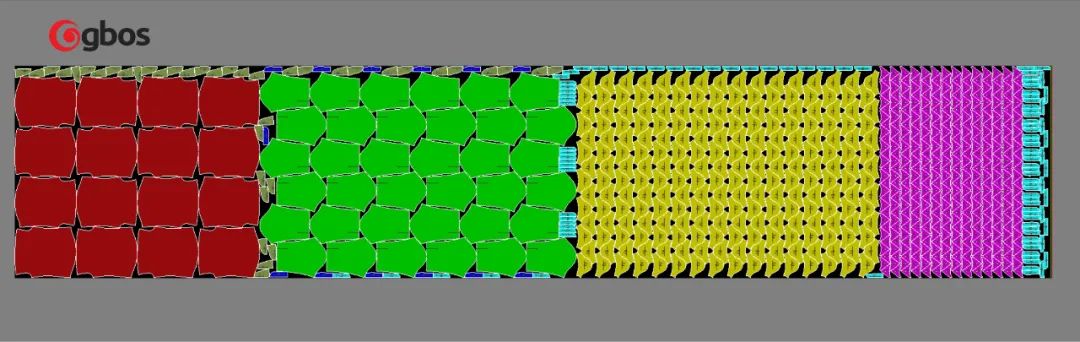

Therefore, we have developed the ITS Rule Material Nesting System and the ITS2/ITS3 AI Intelligent Leather Nesting System, which, through accurate calculation and optimized algorithms, help our customers to achieve significant savings in material costs at the early stage of production, while avoiding inventory backlogs and reducing waste of resources.

(ITS Rules Material Typesetting System)

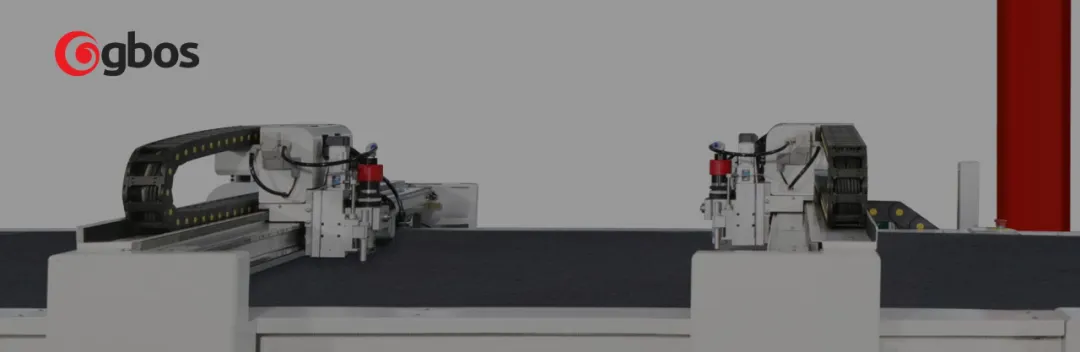

In addition, GBOS next-generation digital cutting center incorporates green concepts into every detail. We utilize advanced digital tools and technologies to maximize the use of electrical energy and reduce energy consumption and carbon emissions. At the same time, by optimizing the cutting process, we reduce material loss and the use of consumables, further reducing the impact on the environment and setting an example of green manufacturing for the industry.

02 Social chapter: people-oriented, guarding operational safety

GBOS understands the principle of “People First” and considers operator safety as its own responsibility. Our intelligent cutting machines are equipped with an advanced motion detection system, which can instantly respond to potential hazards and emergency stop the machine to ensure safe operation. This design not only reflects our deep concern for operators, but also demonstrates GBOS pursuit of excellence in technological innovation.

Meanwhile, GBOS integrates ergonomics into the design of the equipment to create a friendly and convenient operation interface, reducing operator fatigue and enhancing work comfort. These human-oriented designs and innovations not only enhance cutting efficiency, but also create a safe, harmonious and positive workplace atmosphere, so that every employee can grow together in respect and care, and contribute to the sustainable development of the company.

03 Governance: Transparent management to build the cornerstone of trust

In terms of governance, GBOS always adheres to the principles of openness, transparency and integrity, and is committed to building an efficient, clean and responsible corporate image. We are well aware that only by establishing a sound governance system can we ensure the long-term stable development of the enterprise. Therefore, we focus on optimizing and improving our corporate governance structure, strengthening internal control and risk management, and ensuring the compliance and soundness of our corporate operations.

(GBOS Jiangxi Production Base – No. 1 Workshop View)

On this basis, GBOS actively leads the new trend of green supply chain management and works with suppliers to build a sustainable supply chain ecology. We have implemented a rigorous supplier screening and evaluation process to ensure that every link in the supply chain strictly follows safety and sustainability standards, and to safeguard the green quality of our products and services. With the help of cutting-edge digital tools and technologies, our products support green traceability, helping users to easily realize green and transparent management of the supply chain, and jointly promoting the entire industry towards a greener and more sustainable future.

04 Working Together for a Green Future

GBOS will continue to take ESG as the core to lead the manufacturing industry towards green and sustainable development. We will continue to increase technological innovation to improve product performance and service quality; at the same time, we will actively fulfill our social responsibility and governance obligations to set a green, environmentally friendly and responsible model for the industry. We look forward to working with more industry partners to jointly promote the green transformation and sustainable development of the manufacturing industry, and contribute to building a better and more harmonious future.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: