Driven by global economic integration and digitalization, the manufacturing industry is undergoing unprecedented changes. To respond quickly to market changes and meet the diverse needs of brands and consumers, manufacturing companies are actively seeking new technologies and solutions. In this context, Die-Less Cutting technology, with its unique advantages, is leading the transformation of manufacturing and providing companies with more opportunities and competitiveness in the “China+1” industrial transfer process.

Introduction to Die-Less Cutting Technology

Die-Less Cutting technology breaks the limitations of traditional die cutting, bringing unprecedented flexibility and efficiency to the manufacturing industry. This technology, through digitalization and intelligence, allows companies to respond quickly to market demands, achieve rapid design iteration, and personalized customization. This not only helps companies meet the increasingly diverse needs of consumers but also allows them to stand out in fierce market competition.

Application in the “China+1” Strategy

Under the “China+1” strategy, many footwear brands are seeking procurement opportunities outside of China. The introduction of Die-Less Cutting technology is key to helping footwear companies enhance their global competitiveness. By digitizing and automating production processes, companies can reduce production costs, increase production efficiency, and minimize material waste, thereby gaining a more advantageous position in the global market.

Precision and Consistency in Cutting

The precision and consistency of cutting pieces are crucial for the successful introduction of automated sewing and assembly in the later stages of production. Die-Less Cutting technology ensures high precision and consistency for each cut piece, providing reliable support for subsequent automated production. This technical feature significantly enhances the overall efficiency and product quality of the footwear production line, giving companies more competitive advantages in the global market.

Case Studies

In Bangladesh, Die-Less Cutting technology has also gained widespread attention. Many footwear companies have begun to introduce this technology and have achieved significant results. Companies such as Maf, Edison, Apex, Bay, and Youngone have successfully digitized their production processes, significantly improving production efficiency and reducing production costs after introducing GBOS Die-Less Cutting technology. For local sports shoe manufacturers Maf and Edison, the introduction of GBOS Die-Less Cutting technology is revolutionary. Traditional die cutting is time-consuming and labor-intensive, and it limits product diversity and personalization. However, the introduction of Die-Less Cutting technology has completely changed this situation. Maf found that with GBOS Die-Less Cutting technology, they could quickly respond to market trends and consumer demands, achieving rapid product design iteration. Edison discovered that this technology significantly reduced material waste, increased material utilization, and thus lowered production costs. Youngone, by reducing manual operations, improved production efficiency and shortened delivery times.

For local sports shoe manufacturers Maf and Edison, the introduction of GBOS Die-Less Cutting technology is revolutionary. Traditional die cutting is time-consuming and labor-intensive, and it limits product diversity and personalization. However, the introduction of Die-Less Cutting technology has completely changed this situation. Maf found that with GBOS Die-Less Cutting technology, they could quickly respond to market trends and consumer demands, achieving rapid product design iteration. Edison discovered that this technology significantly reduced material waste, increased material utilization, and thus lowered production costs. Youngone, by reducing manual operations, improved production efficiency and shortened delivery times.

For leather shoe company Apex, the introduction of GBOS Die-Less Cutting technology has also brought significant changes. In both pattern room use and mass production, Apex has achieved a leap in production capacity and cost reduction through this technology. First, Die-Less Cutting technology allows Apex to adjust product designs more flexibly to meet market and consumer needs. Second, this technology significantly increases material utilization and reduces material costs through precise cutting and waste reduction. Finally, with the introduction of automated and intelligent equipment, Apex has reduced manual operations and improved production efficiency.

These changes make Apex more competitive in both the Bangladeshi and global markets. Through Die-Less Cutting technology, Apex can provide higher quality, more competitive products, winning the trust and favor of consumers.

Summary of Case Studies: 5 Key Savings and Their Value

-

Energy Savings:

By using GBOS Die-Less Cutting technology, companies can significantly reduce energy consumption in production. Traditional die cutting requires a lot of electricity, but the efficient digital operation of Die-Less Cutting technology greatly lowers energy use. This not only reduces production costs but also aligns with modern manufacturing’s energy-saving and emission-reduction trends.

-

No Need for Dies:

Die-Less Cutting technology eliminates the need for traditional dies, meaning companies no longer need to design and manufacture dies for each product, saving time and costs. Traditional die design and manufacturing are time-consuming and expensive, while Die-Less Cutting allows direct digital cutting, improving production efficiency and reducing preparation time.

-

No Die Cutting Boards:

Since Die-Less Cutting technology doesn’t require dies, there is no need for die cutting boards either. This reduces the use of equipment and lowers the maintenance and replacement costs of cutting boards, which wear out during use and need regular replacement, a problem avoided with Die-Less Cutting.

-

No Die Storage:

Traditional dies require a lot of storage space, and different products need different dies, making storage management complex and costly. Die-Less Cutting technology is fully digital, eliminating the need for physical die storage, significantly reducing storage space and management costs, and improving warehouse utilization.

-

Labor Cost Savings:

Die-Less Cutting technology is highly automated, reducing reliance on manual labor. Traditional die cutting requires extensive manual operations, including design, manufacturing, installation, and maintenance of dies. Die-Less Cutting simplifies these processes through digital operations, cutting labor costs, reducing the risk of human error, and improving production accuracy and consistency.

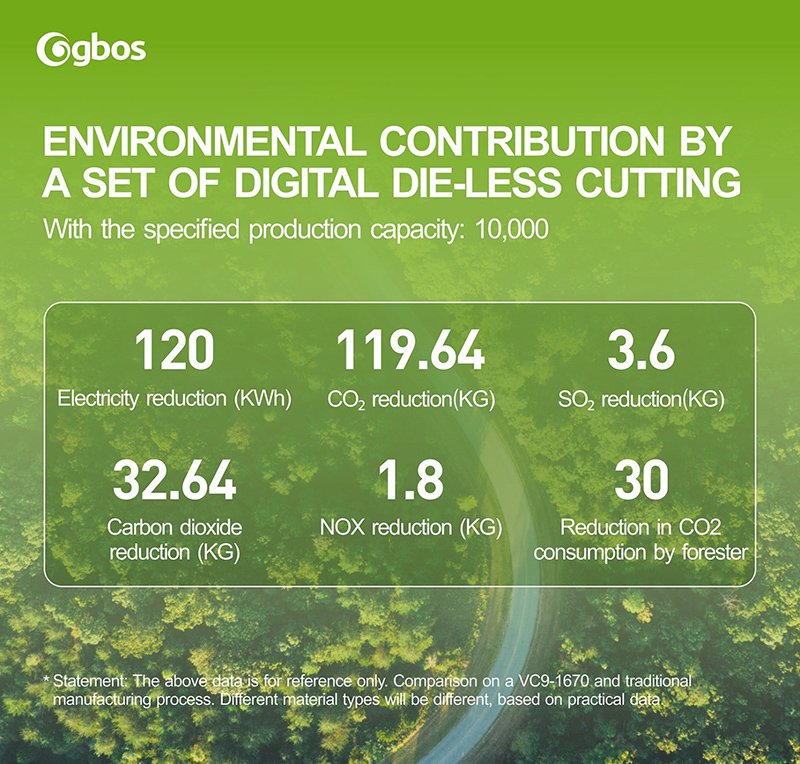

ESG Strategy and Corporate Social Responsibility

Using Die-Less Cutting technology benefits companies not only by reducing production costs and improving efficiency but also by demonstrating positive contributions in environmental, social, and corporate governance (ESG). By reducing energy consumption and carbon emissions, companies can practice green manufacturing, contributing to the protection of the planet and sustainable development. This not only enhances the company’s social image but also attracts more environmentally conscious consumers, further strengthening market competitiveness.

Each GBOS Die-Less Vibrating Knife Cutting Machine performs excellently in energy saving and emission reduction, providing strong support for the green and sustainable development of the manufacturing industry.

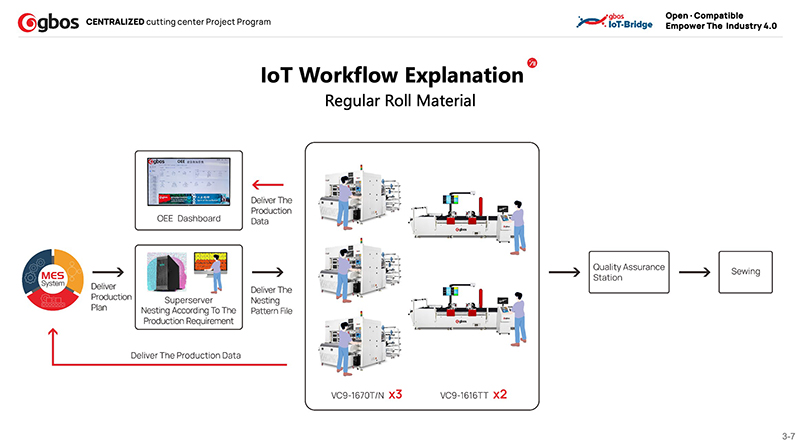

Digitalization

All Die-Less Cutting technologies can easily achieve real-time monitoring of equipment operation, usage details, and overall efficiency through GBOS’s IoT Bridge, providing strong support for company decision-making. At the same time, IoT Bridge can achieve data intercommunication between devices, promoting continuous optimization and development of enterprises.

In the process of digital development and Industry 4.0, the introduction of Die-Less Cutting technology is undoubtedly the trend of the manufacturing industry and an effective means to enhance core competitiveness. Through this technology, manufacturing companies can gain more opportunities and competitiveness in the global market and meet future challenges.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: