Looking back at the year 2023, GBOS recount our growth.

Each step witnessed the progress and determination of GBOS’s people

We’ve documented every exhibition, every event, every product launch, every journey,

and every act of kindness through pictures.

We’ve used words to convey that GBOS, with unwavering dedication,

has strived to present outstanding results.

Now, let’s take a closer look at 2023 through five significant events.

01 Unveiling a New Brand Image, Embarking on Lean Manufacturing 4.0 with Users

On September 26, 2023, during CISMA, GBOS introduced its new brand upgrade to VIP users from the global clothing manufacturing industry. The event marked the unveiling of GBOS’s new brand image and slogan, “Cutting Edge for Tomorrow.”

This new brand image signifies GBOS’s more systematic “digitalization, scaling, and standardization” operational framework. In the future, GBOS will work alongside users in the four core areas of “digital cutting systems, digital laser equipment, non-standard/automation, and IoT Bridge” to embrace Lean Manufacturing 4.0!

Learn more:

GBOS Brand Upgrade: Cutting Edge for Tomorrow

02 A Global Garment Industry Feast, GBOS Guides the Future with “Diverse Innovative Technology”

CISMA, a global stage for “intelligent sewing and digitalization solutions,” gathered renowned brands from the industry worldwide. GBOS also participated with a fresh look and the latest technological prowess, meeting VIP users from around the world at CISMA 2023.

At the event, GBOS showcased three core sections: “Digital Cutting Zone,” “Process Innovation Zone,” and “Digital Dashboard Display Zone.” Users experienced AI nesting workstations, high-precision digital cutting, efficient laser cutting, denim laser washing technology, seamless technology, and intelligent laser technology. All of this showcased the more advanced and comprehensive intelligent manufacturing technology.

Learn more:

CISMA: From 2011 to 2023, Never Absent!

GBOS Takes AI Vision One Step Further in Garment Manufacturing Industry

A niche choice in the lingerie industry: creating a unique boutique line!

“Intelligent Keeper” – The Artisanal Heritage and Innovation of Leather Craftsmanship

03 Accelerating Globalization, Spreading Chinese Intelligent Manufacturing Worldwide

With 18 years of accumulation, GBOS has reached the international advanced level in the field of flexible intelligent manufacturing equipment.

As GBOS accelerates its globalization and captures future industry trends, it aims at the advanced technology in the field of flexible intelligent manufacturing equipment and actively explores innovation.

In 2023, GBOS showcased the “Digital Cutting Center” solution to global users in countries such as the United States, Italy, Indonesia, and Vietnam, based on industries like footwear, garment, and automotive interior. GBOS empowered the global market with “innovative manufacturing” and demonstrated China’s intelligent manufacturing capabilities!

Today, GBOS’s flexible intelligent manufacturing solutions are used in over 90 countries and regions worldwide, holding a prominent position in their respective fields.

Learn more:

GBOS ITMA Highlights Reviewing

Reviewing ∣ Texprocess Americas 2023

Live coverage: GBOS at SaigonTex 2023 in Vietnam

Let’s Take a Peek at Vietnam Footwear Exhibition!

GBOS in Vietnam | Intelligent Footwear 4.0

Invitation∣We are waiting for you to explore solutions for the footwear industry!

After adding new production lines, this shoe factory creates intelligent workshops again!

Digital Cutting Center, Open and “Same Frequency”.

04 Delving Deeper into Multiple Flexible Industries, Innovating More High-Quality Solutions for Users

From high die-cutting costs to rising raw material costs, from fluctuating labor quantities to increasingly urgent delivery pressures, traditional flexible manufacturing industries are facing a series of severe challenges. Digitalization is the answer to these challenges.

In this year, we appeared with industry solutions at exhibitions such as the Shenzhen Underwear Show, Guangzhou Shoe Show, Jinjiang Shoe Show, Putian Shoe Show, Wenzhou Shoe Show, Shanghai Shoe Show, Shanghai CISMA, Shenzhen Electronics Show, South China Printing Show, South China International Sewing Show, Guangzhou Fair, and Wuhan Automotive Interior Show.

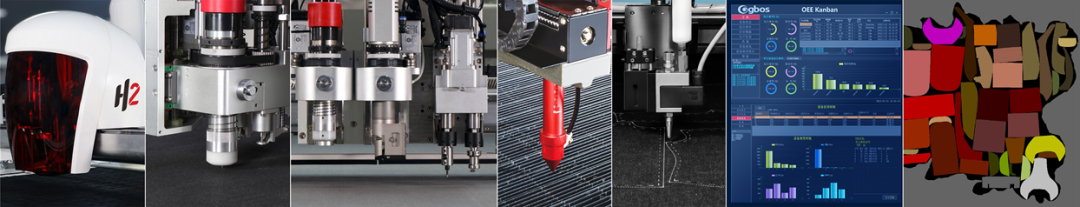

In addition, we participated in technology exchange meetings in Shanghai and Yudu, Jiangxi. We hosted multiple new product launches in Jinjiang, Guangzhou, and Shanghai, introducing innovations in various industries and applications, such as the 2nd generation high-ply cutting bed – H2, the 5th generation VC9-1670T/N-4SCCD, the 3rd generation ITS3-3012, the third-generation VC9-1616TT, and more. These innovations empower more users to achieve Lean Manufacturing.

Learn more:

Global Debut: GBOS Released New Products in Jinjiang!

Hit the 2023 Guangzhou Shoes Exhibition丨GBOS Joins You, Cutting Edge for Tomorrow

Technology Meets Innovation| GBOS One-stop Intelligent Solution in Shanghai Automotive Conference

05 Practicing Corporate Social Responsibility

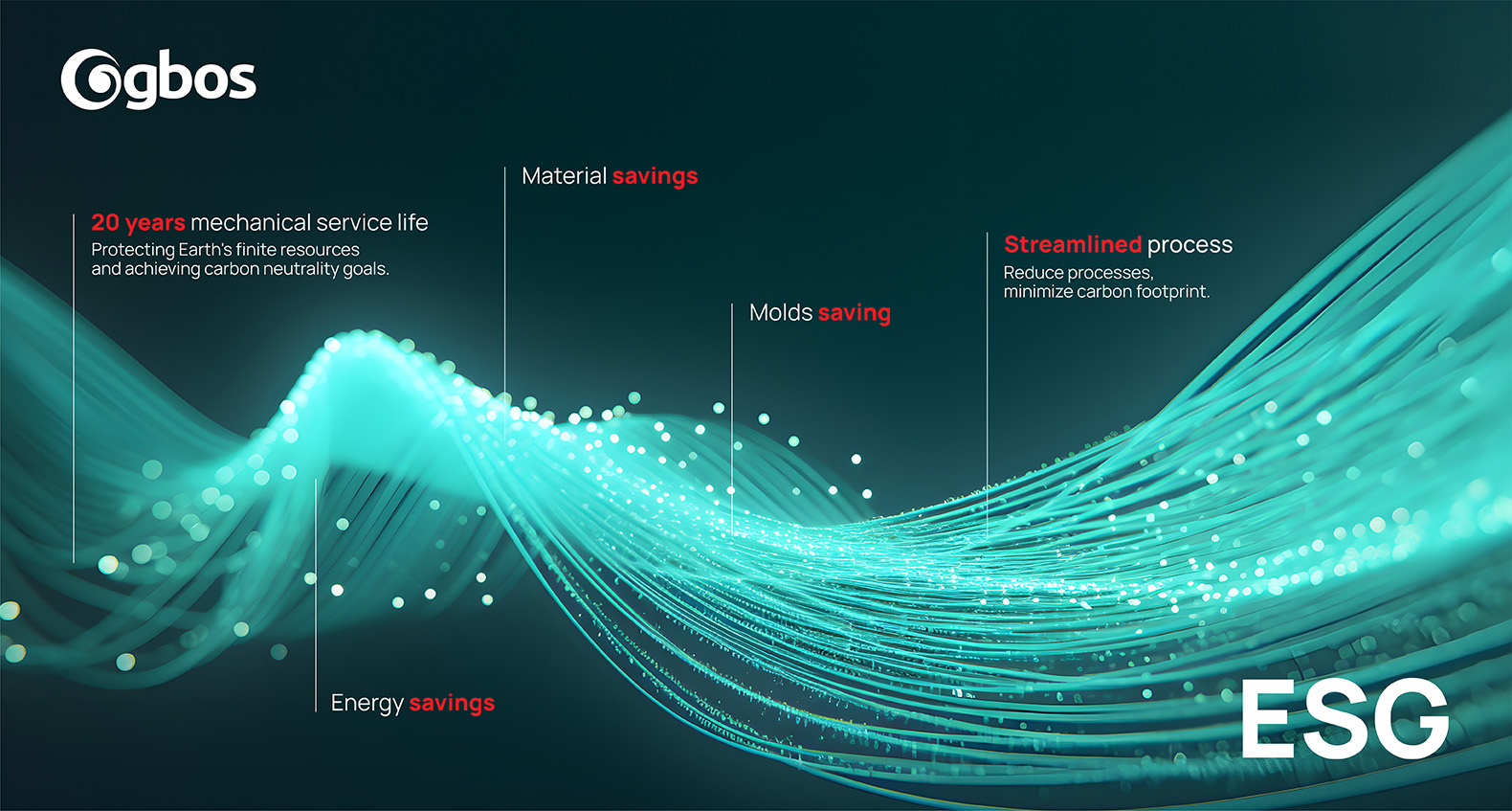

In 2023, GBOS focused on two dimensions for corporate social responsibility: “Empowering Users to Achieve ESG” and “Practicing the Company’s Own ESG Social Responsibility.”

For green manufacturing that assists the manufacturing industry, GBOS empowers users to achieve ESG from multiple dimensions, including “Intelligent Cutting Equipment to Aid Green Intelligent Manufacturing,” “IoT Bridge to Help Enterprises Break Data Silos and Achieve Paperless Production Management,” and “Localized Services to Reduce Carbon Emissions from Large-scale Transportation.”

Regarding corporate social responsibility, GBOS helped autistic children, provided aid to the Gansu earthquake-stricken area, and assisted during the Jilin flood. This gave every GBOS employee and partner a sense of upward and virtuous values!

Note: For every GBOS product purchased, an amount ranging from 50 to 1000 yuan will be donated to charity!

Learn more:

Under the ESG concept, the “green manufacturing” way of manufacturing industry

GBOS Charity Foundation is in action to help Jilin!

Caring for Children with Autism, Practice Social Responsibility

Stay tuned for a new chapter of GBOS 2024!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: