The leather and footwear industry around the world is witnessing a paradigm shift in the way products are manufactured using laser technology.

As we can see, traditional leather cutting:

Obviously, in the production of bags, shoes, suitcases, boots, handbags and all other types of footwear, leather cutting by craftsmanship, we can meet the following problems:

-

1) Have an influence on product consistency.

-

2) Staff instability.

-

3) It’s different to achieve complex graphics cutting.

-

4) No guarantee of product quality.

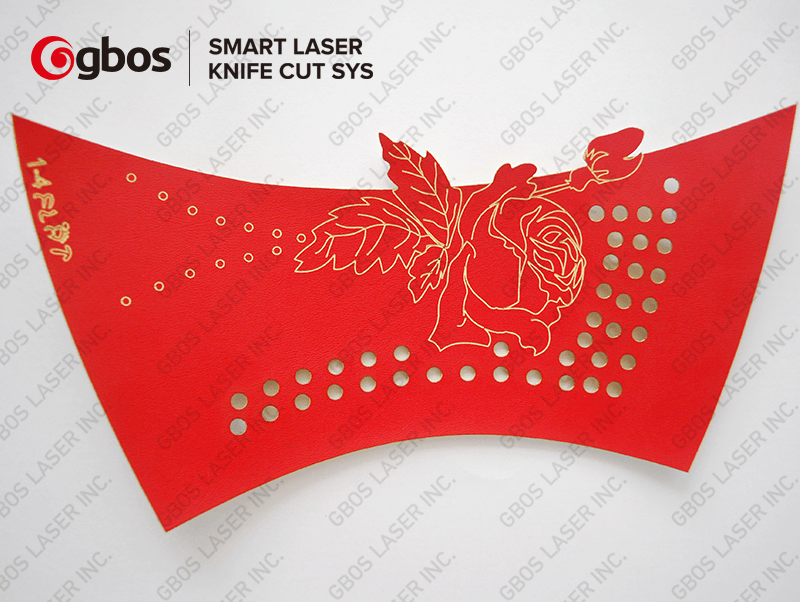

Laser can solve all. What’s more, laser cutting/marking/engraving leather will create more contribution to traditional art-craft.

Now-day, fashion is popular, and the personalization is the trend. How to create competitiveness for your enterprise? How to follow the popularity? —— By using laser engraving/cutting machine.

Enterprise enjoy shorter delivery and quicker responsiveness for their customers in high demand design. In other words, small volume and large-variety orders can be completed in time! Products can enter the market more faster! Design more creativity and unique! More efficient cutting/engraving way!

Here, high speed laser marking/cutting/engraving machine for personalized customization.

Some details:

- 1) Red light preview.

- 2) Large working area, maximum 600*600mm. (the processing area is adjustable)

- 3) Speed increased up 20%.

- 4) Compact structure ,easy operation.

Click and know more about this leading machine!

Are you ready for transforming to smart manufacturing for your shoe, bags, automotive, etc industry?

What’ s more, provide you multi-layer leather cutting and punching intelligent solutions! —— Click here!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: