As the seasons shift, nature’s palette begins to turn once more—the air grows milder, life flourishes, and the world of fashion steps into the vibrant wave of seasonal change. In this dynamic and fast-paced moment, the apparel industry is racing to launch its latest collections. Amid the complexity and variety of seasonal garment production, a cutting machine that can meet these demands with precision has undoubtedly become the center of attention.

Developed by GBOS, the multifunctional single-layer digital knife cutting system VC9-1820SSCCD is a faster digital cutting solution designed for small-batch and irregular production. This machine brings unprecedented convenience and efficiency to your garment manufacturing process.

01 Precision in plaids and stripe alignment — showcasing the beauty of stripes

With the arrival of spring, striped shirts and T-shirts have become wardrobe favorites. However, in the production of striped garments, achieving precise pattern and stripe alignment has long been a challenge for apparel manufacturers.

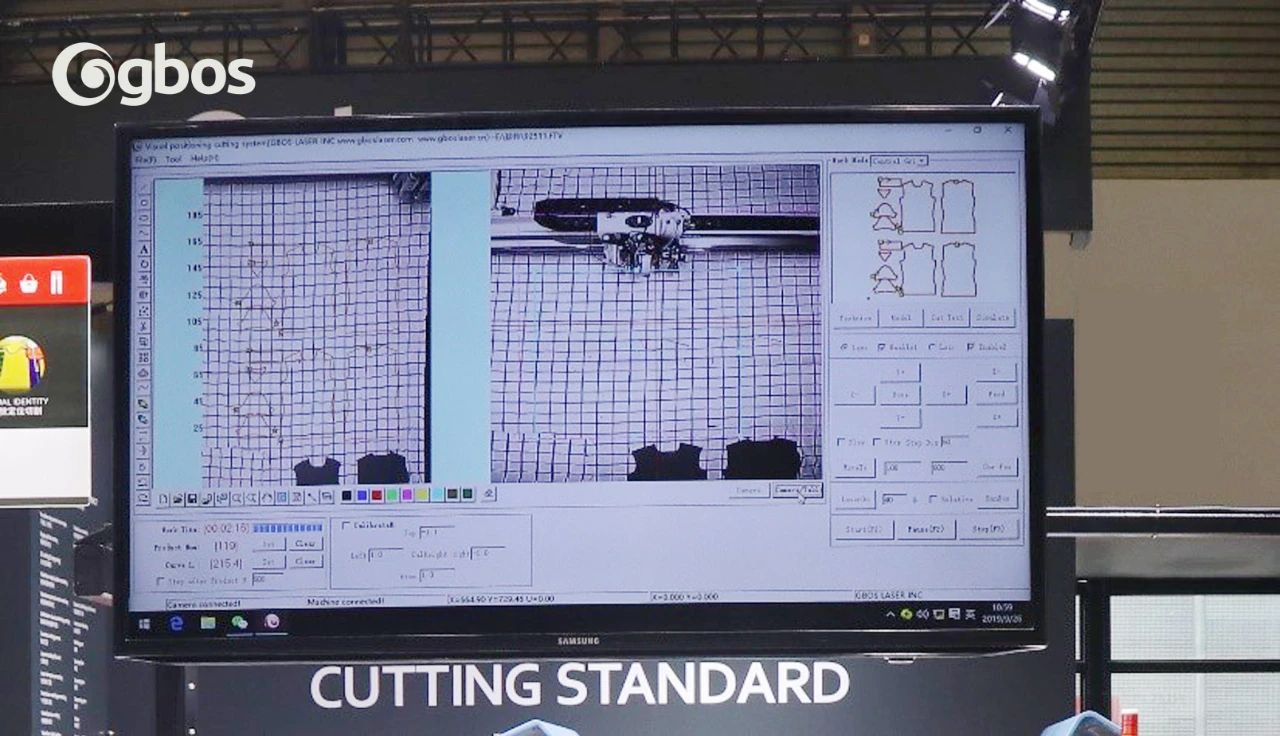

Equipped with an AI VisionScan system, the VC9-1820SSCCD accurately detects stripe direction and spacing, enabling precise pattern and stripe alignment during cutting.

Whether it’s fine, delicate pinstripes or bold, wide stripes, the AI VisionScan system ensures that every cut piece aligns perfectly. This attention to detail enhances the quality of striped garments, delivering an exceptional wearing experience for consumers.

02 Precise Cutting for Digital Prints — Unleash Creative Energy

Basketball jerseys, football shirts, and other digitally printed sportswear are highly favored during the sports season. The VC9-1820SSCCD, with its powerful visual recognition capabilities, precisely identifies and cuts digital print materials.

The edges of the printed patterns are neat and smooth, free from frayed edges or jagged flaws, fully showcasing the vibrant colors and intricate designs of digital prints. This helps sportswear stand out on the field, releasing boundless creative energy.

03 Multifunctional Modules — Meeting Diverse Process Demands

The VC9-1820SSCCD is equipped with multiple modules, including the “oscillating knife cutting device, rotary knife cutting device, V-notch device, rotary punching device, and brush device.”

These versatile devices enable the machine to effortlessly handle various process applications. Whether it’s corner cutting, punching, or delicate brush markings, the VC9-1820SSCCD excels in all, providing a one-stop solution for the diverse manufacturing needs of the apparel industry.

As the season changes, the apparel industry faces both great opportunities and challenges. Choosing GBOS means choosing efficiency, precision, and quality, giving you a competitive edge in the garment production race and bringing more fashionable, high-quality seasonal clothing to consumers.

Let’s join hands this spring and open a new chapter in garment production with the VC9-1820SSCCD.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: