The development of China’s automotive industry has transformed from weak beginnings to remarkable prosperity, marking a significant historical chapter. As the market shifts from rapid expansion to stable competition, the automotive sector stands at a new historical juncture, facing fresh opportunities for globalization. This is not just a challenge but a golden period for Chinese automotive brands to showcase their strength on the global stage and strategize anew.

01 Innovative Manufacturing in Automotive Interiors: Key to Enhancing Market Competitiveness

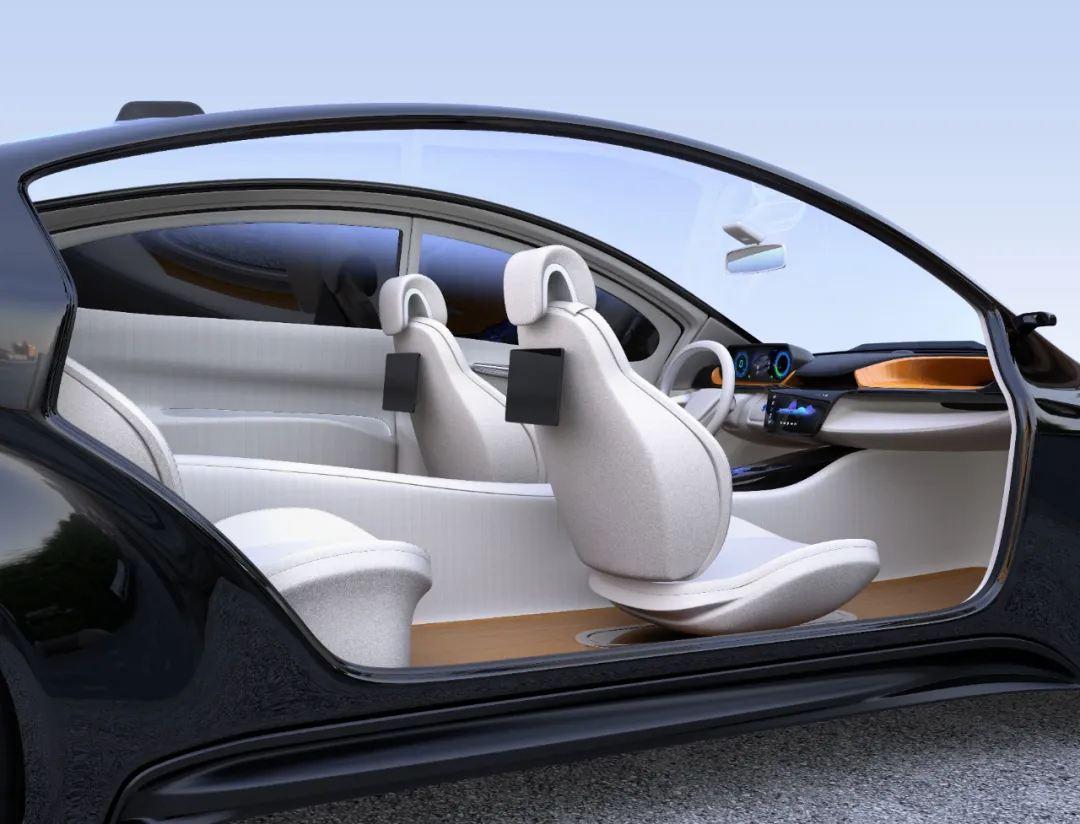

Among various manufacturing stages, the design and production of automotive interiors are crucial. They impact vehicle aesthetics, functionality, consumer experience, and market competitiveness. With increasing demands for intelligent, high-quality, and timely delivery from brands and manufacturers, interior manufacturers must adopt effective strategies, innovating and optimizing processes to meet these high standards.

02 Growth Strategies for Interior Manufacturers

To maintain a competitive edge, interior manufacturers should implement strategies such as increasing R&D investment, promoting technological innovation, enhancing manufacturing processes, ensuring product quality and consistency, and utilizing advanced digital production management systems to improve decision-making and responsiveness to market changes.

GBOS excels in implementing these strategies, offering one-stop smart cutting and innovative process solutions for automotive interiors.

This includes:

-

Leather Layout and Cutting Solutions

- A large format leather typesetting system ITS5-3012, equipped with 2-3 large format vibrating knife cutting machine KC3060TTX2-4P, to achieve continuous operation, effectively shorten the production cycle of the product, and enhance the efficiency of enterprises;

- The system supports multi-component and multi-method mixed layout, allowing for manual intervention. The layout utilization rate can reach 85% or higher, maximizing material savings.

- The large-format vibration knife cutting machine KC3060TTX2-4P is equipped with multiple projection positioning systems, enabling real-time loading, feeding, cutting, and unloading, thereby enhancing precision and efficiency.

- Reducing environmental pollution and resource waste promotes sustainable industrial development, reflecting the principles of ESG regarding environmental protection and social responsibility.

- Equipped with an OEE digital dashboard, the system enables visual management of the production process, enhancing the transparency of production data.

-

Innovative Process Solutions

- The XXP4-180 high-speed vibrating mirror laser cutting system is a single-machine solution that can be used for leather marking, cutting, hollowing, texturing and other processes.

- Utilizes ROFIN metal laser tubes for ultra-fine engraving, capable of processing complex graphics and personalized designs to boost market competitiveness.

As we look forward to the new journey of the Chinese automotive industry in globalization, leveraging advanced interior manufacturing technology will enable brands to seize opportunities and tackle challenges. With an open and innovative approach, Chinese automotive brands will continue to progress, contributing to the global automotive industry and showcasing the pride of Chinese manufacturing!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: