As the 18th China International Automotive Interiors and Exteriors Exhibition (CIAIE) concluded on August 4, 2024, at the Shanghai New International Expo Centre, a grand showcase of cutting-edge technology and innovative thinking in global intelligent manufacturing came to a successful close.

This exhibition not only witnessed the vigorous development of the automotive interiors and exteriors industry but also provided an excellent platform for exchange, mutual learning, and collective advancement within the industry. Guangboshi, as an innovator in the field, made a stunning appearance with its one-stop digital intelligent cutting and innovative processing solutions, showcasing the extraordinary charm and forward-looking vision of Chinese manufacturing to the world.

1. Focused Exhibition Stand: A Feast of Technology, Highly Acclaimed

At the exhibition, Guangboshi’s booth N2A001 quickly became the center of attention due to its meticulously designed layout and outstanding technological displays. Visitors from around the globe were deeply impressed by the professionalism and quality service provided by Guangboshi’s on-site technical and sales teams, leading them to stop by and explore.

|

|

One particularly notable moment was when an international client from Iran showed great interest in Guangboshi’s innovative laser marking machine. After experiencing the sample testing on-site, the client was full of praise for the product’s high precision, speed, and customization capabilities. This not only deepened their recognition of the product’s performance but also enhanced their trust and confidence in Chinese manufacturing brands.

2. Innovative Technology: Empowering from Multiple Dimensions

We didn’t limit ourselves to showcasing a single product at this event. Instead, we proudly presented a comprehensive solution that integrates intelligent cutting and innovative processes, together with exceptional quality, to deeply penetrate the automotive interiors and exteriors sector. This solution precisely empowers the industry to move towards a future characterized by lightweight, customized, personalized, and sustainable development.

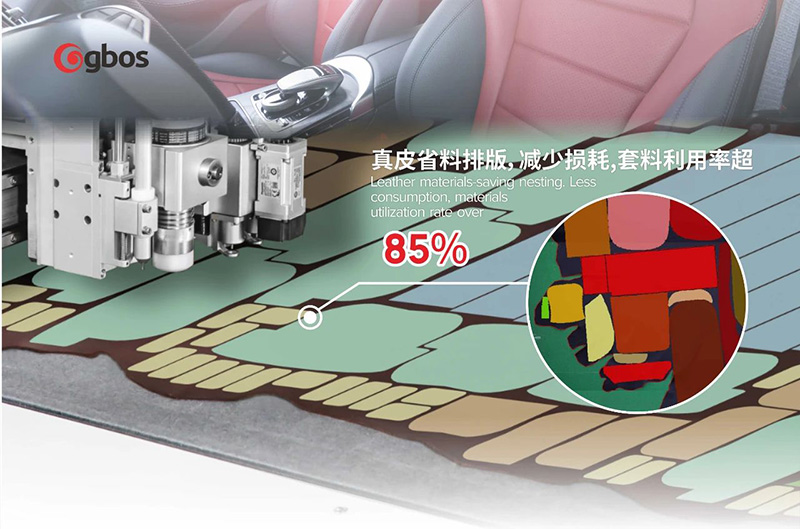

Our solution system is complete, covering everything from high-precision layout and cutting processes for automotive interior leather, to complex 3D five-axis laser cutting technology for irregular components, car lights, and injection-molded parts; from the meticulous handling of stitching codes to personalized laser perforation and engraving on interior leather; and even to the precise cutting of 3D mesh and airbag fabrics. This comprehensive approach meets the diverse needs of automotive interiors and exteriors manufacturers.

This is more than just the presentation of a solution; it is the crystallization of Guangboshi’s deep understanding of the automotive industry. We leverage the power of integrated innovation to bring unprecedented innovation and upgrades to the automotive interiors and exteriors industry.

3. Problem Solving: Professional Insights and Targeted Solutions

During the exhibition, the Guangboshi team engaged in in-depth exchanges with on-site users, gaining precise insights into the challenges faced by automotive interiors and exteriors manufacturers at the cutting end. Addressing issues such as improving production efficiency, cost control, handling customized orders, optimizing material utilization, and cutting irregular products, Guangboshi, with its rich industry experience and professional technical strength, provided users with detailed and practical solutions. These solutions not only helped users solve pain points in actual production but also laid a solid foundation for their sustainable development in the future.

As the CIAIE exhibition came to a successful conclusion, Guangboshi’s journey of innovation continues.

We will persist in our customer-centric service philosophy, continuously driving technological innovation and industrial upgrades, and bringing more surprises and possibilities to the automotive interiors and exteriors industry. We thank every customer for their trust and support, and we look forward to exploring the endless possibilities of the automotive interiors and exteriors industry with more partners in the future, and jointly writing a new chapter in the “Digital Cutting Center+” of the automotive interiors and exteriors industry.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: