At the Guangdong International Intelligent Shoe Machine Equipment Exhibition and Shoe Material Supply Chain Exhibition held from June 2 to 4, 2024, GBOS once again injected high-quality development momentum into the footwear industry with its outstanding technical strength and innovation capabilities, leading the industry towards a greener and more sustainable future.

- Continuous Success and Wide Recognition for Technical Strength

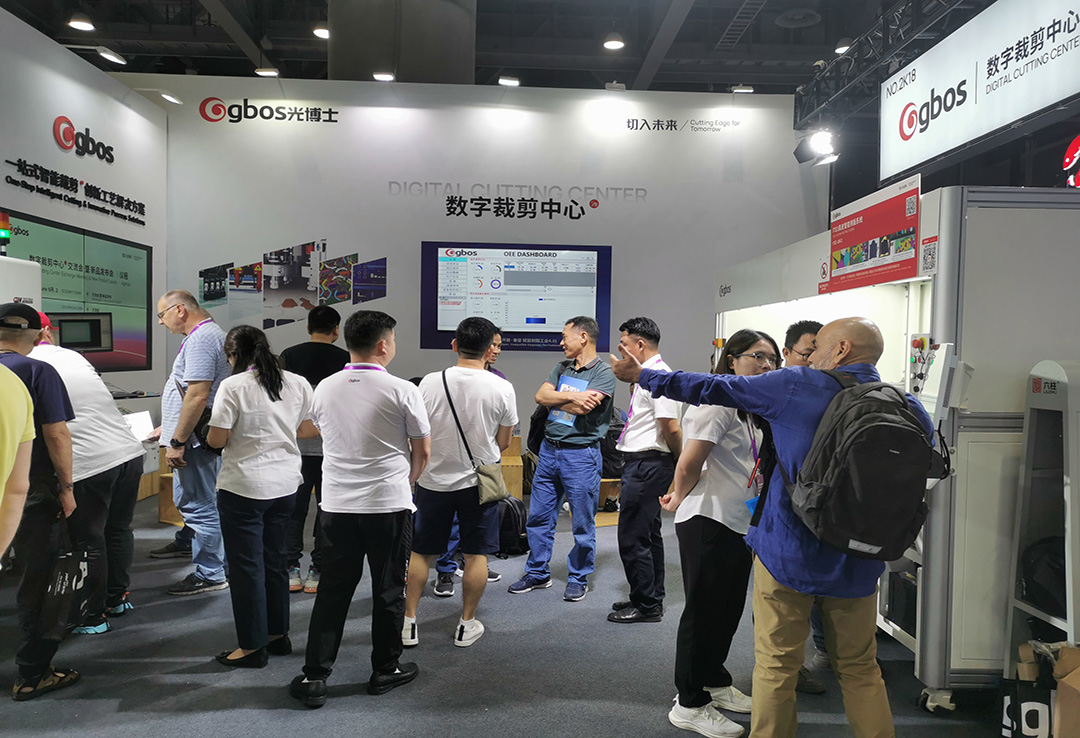

During the exhibition, GBOS garnered the favor of numerous customers, resulting in a continuous stream of orders. This is not only a high affirmation of our products and services but also a recognition of the brand strength and technological innovation capability of GBOS. We feel honored and responsible and will continue to win more customer recognition with our strength and technology, contributing more to the development of the global footwear industry.

|

|

- New Product Launch: Stunning Debut of the Smart Industrial Bee MAX

On the first day of the exhibition, GBOS CEO Mr. Liu Wen unveiled the new product – Smart Industrial Bee MAX. This industrial equipment, combining aesthetics and ergonomics, is designed for scenarios such as shoe “development rooms, sample rooms, and integrated cutting of leather.” The addition of Smart Industrial Bee MAX not only enriches the Smart Industrial Bee product family but also broadens its application scenarios and scope, meeting the needs of different users.

- Digital Cutting Center: Empowering High-Quality Development of Traditional Manufacturing

In response to market demands and industry development trends, GBOS has meticulously crafted a series of digital one-stop intelligent cutting and innovative process solutions. These solutions include:

- Nesting and cutting of regular materials

- Leather material-saving nesting and cutting

- Multi-layer auxiliary material cutting

- High-speed marking of shoe material pieces

- AI recognition and cutting of same-color mesh fabrics

- Punching of positioning holes and cutting process

- Integrated fur material cutting and ITS3 cardboard matching functionality

By integrating GBOS’s self-developed IoT Bridge technology, unified management of the manufacturing workshop can be easily achieved. This effectively breaks data silos and promotes the production process towards greater intelligence and technological advancement.

Continuing the Path of Innovation

|

|

|

|

Guangdong International Intelligent Shoe Machine Equipment Exhibition and Shoe Material Supply Chain Exhibition successfully concluded on June 4, 2024. However, GBOS’s journey of research and innovation does not end here. We look forward to bringing more high-quality solutions to empower the industry’s high-quality development in the future.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: