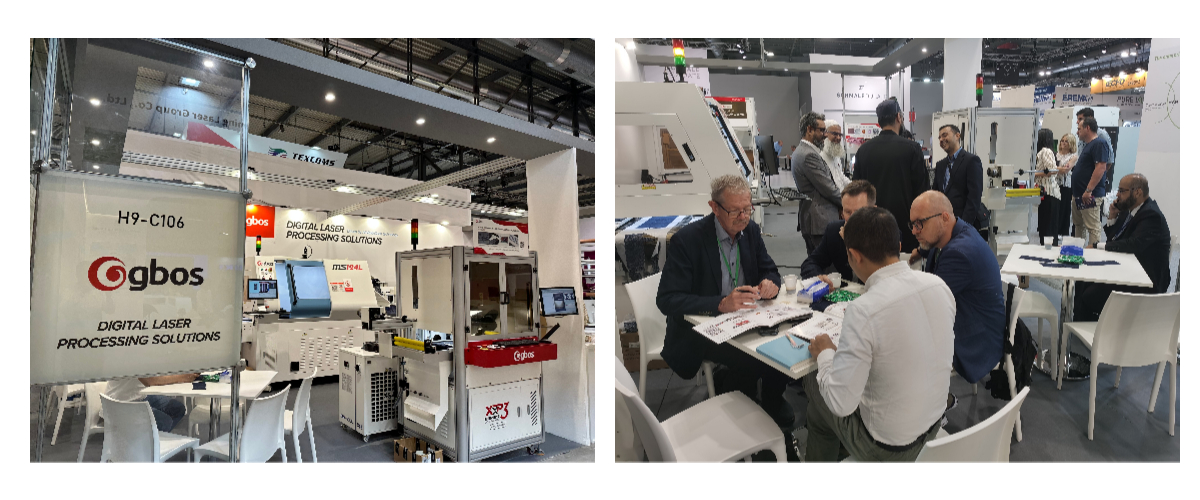

The SIMAC TANNING TECH 2024 exhibition in Milan, Italy, proudly celebrates its 50th anniversary, marking a half-century of excellence in the footwear, fashion, and leather industries. As a leading global event, SIMAC has not only gathered top industry elites to discuss trends but also provided a stage for cutting-edge technologies to shine. Since 2003, **GBOS** has stood alongside SIMAC, witnessing countless moments of innovation and transformation, and together we have written an extraordinary chapter of mutual growth and progress.

01 From Startup to Global Expansion

In 2003, GBOS embarked on its journey with SIMAC, driven by a visionary approach and unwavering conviction. At that time, we were a small, emerging company, but full of passion for technological innovation and dreams of global impact. Our consistent participation in SIMAC provided a valuable platform to showcase our latest technological achievements and exchange insights with industry leaders, and it became a significant opportunity to take Chinese manufacturing to the world.

Over time, with SIMAC as our witness, GBOS has grown from humble beginnings to a global innovation powerhouse. Through relentless exploration and breakthroughs in technology, we have gradually made our mark in the industry. We expanded from a single field into multiple specialized sectors, and our innovations have been widely acclaimed in both domestic and international markets, continuously earning high praise.

02 Technology-Driven Innovation: Leading the Way

The growth of GBOS has been fueled by its persistent pursuit of technological innovation. At the SIMAC 2024 exhibition (held from September 17 to 19, 2024), we presented our latest Digital Cutting Center, an all-in-one intelligent cutting solution. This includes the ITS3-3012 Intelligent Leather Material Optimization System, designed for materials like genuine leather, fur-leather composites, semi/full leather, and crocodile leather. The system optimizes material usage, achieving an impressive 85% or higher utilization rate.

We also introduced the Bee Max to the European market for the first time. This versatile machine is suited for diverse applications such as sample rooms, development rooms, and board centers. It can perform layout and cutting simultaneously, efficiently handling “template-matching” mode for fur-leather materials, as well as preview projection and cutting for leather fragments. Equipped with a high-quality industrial camera and leather layout system, the machine can handle multiple processes for cutting leather materials.

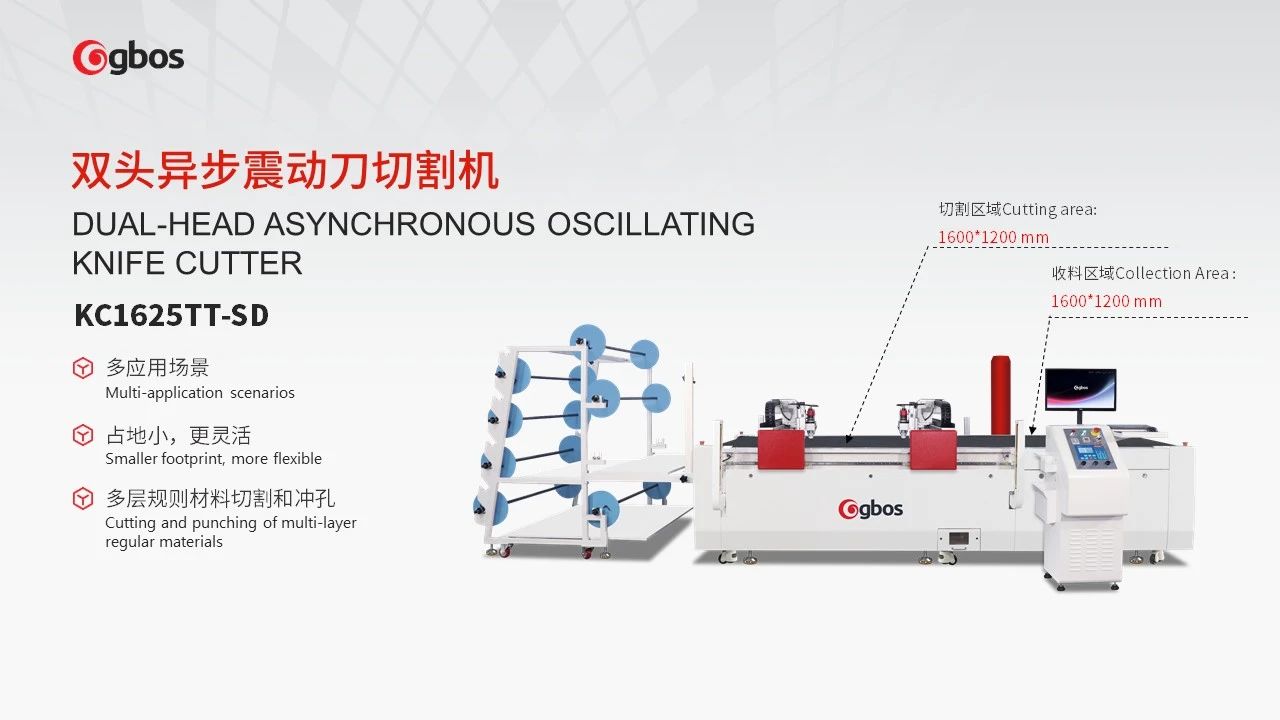

Additionally, our mass production model, the KC1625TT-SD Multi-Layer Cutting Solution for Regular Materials, features a dual-head asynchronous cutting system, ensuring efficient and precise multi-layer cutting of various leather materials, auxiliaries, and flexible fabrics. The machine’s integrated body structure guarantees long-term stability, ensuring years of reliable use without deformation.

By consistently introducing products and technologies that lead industry trends, GBOS has not only enhanced its core competitiveness but also contributed significantly to the transformation and upgrading of the entire industry.

03 Looking Ahead: A Future of Collaboration and Success with SIMAC

As we stand at this new historical milestone, GBOS remains committed to the principles of “innovation, collaboration, and shared success.” We will continue to work closely with SIMAC and our global partners to explore new directions and pathways for industry development. GBOS believes that in the days to come, we will continue to advance with greater confidence and steady steps toward an even brighter future.

We also look forward to partnering with like-minded enterprises and individuals to drive the prosperity of the footwear, fashion, and leather industries. Together, let us anticipate a future where GBOS, under the witness of SIMAC, will write an even more brilliant and dazzling new chapter!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: