From September 3 to 5, 2024, the global leather industry once again focused its attention on the Shanghai New International Expo Centre, where the 2024 All China Leather Exhibition (ACLE) concluded with great success. The event, showcasing a fresh new look, successfully built a business bridge between international and domestic companies while driving technological innovation in the leather industry. This injected new vitality into the development of leather products, fostering their prosperity.

On this international stage, GBOS made an impressive appearance with its theme of “Innovative Technology.” Located at booth W1-D7A, we demonstrated GBOS’s latest R&D achievements in the leather industry through a series of interactive displays and demonstrations. We showcased genuine leather solutions tailored for the footwear, automotive interiors, and luggage industries, and successfully signed multiple orders on-site!

1. Spotlight on Innovation: Technology Empowering the Leather Industry Ecosystem

Among numerous exhibitors, GBOS stood out with its theme of the “Digital Cutting Center” at booth W1-D7A, captivating global attendees with a meticulously designed display area and dynamic live demonstrations. The booth showcased the latest technological achievements in leather processing, along with specialized solutions for industries such as footwear, automotive interiors, and luggage. This attracted the attention of many professionals from both domestic and international markets.

Entering the thoughtfully arranged exhibit, four star products took center stage, each drawing the gaze of the audience. Leading the lineup was the AI Intelligent Nesting System (ITS3-3012), which uses cutting-edge algorithms and precise layout capabilities to usher in a new era of leather processing. Following closely was the Intelligent Genuine Leather Digital Cutting System (KC1630TT-RT-3P), showcasing superior cutting precision and efficiency, exemplifying modern industrial aesthetics with a motto of “Precision and Efficiency.” The Smart Industrial Bee MAX (VC9-3010TT-2SCCD), with its unique branding of “Making Industry Sweeter,” seamlessly combined automation and user-friendliness, adding a touch of warmth to leather production. Meanwhile, the AI Vision-Scan Digital Cutting Machine (VC9-1670T/N-4SCCD), equipped with advanced AI vision technology, made a significant leap forward in intelligent cutting processes, becoming one of the brightest stars of the exhibition.

In addition, the booth presented the IoT Bridge Digital Management System, acting as the smart hub of the manufacturing process. It enabled real-time monitoring, comprehensive TPM maintenance management, and equipment status tracking. IoT Bridge broke down traditional data silos, creating a seamless flow of information while making production management more efficient and effortless. This smart-driven environment offered users a streamlined and worry-free manufacturing experience.

2. Success in Sight: Impressive On-Site Contract Signings

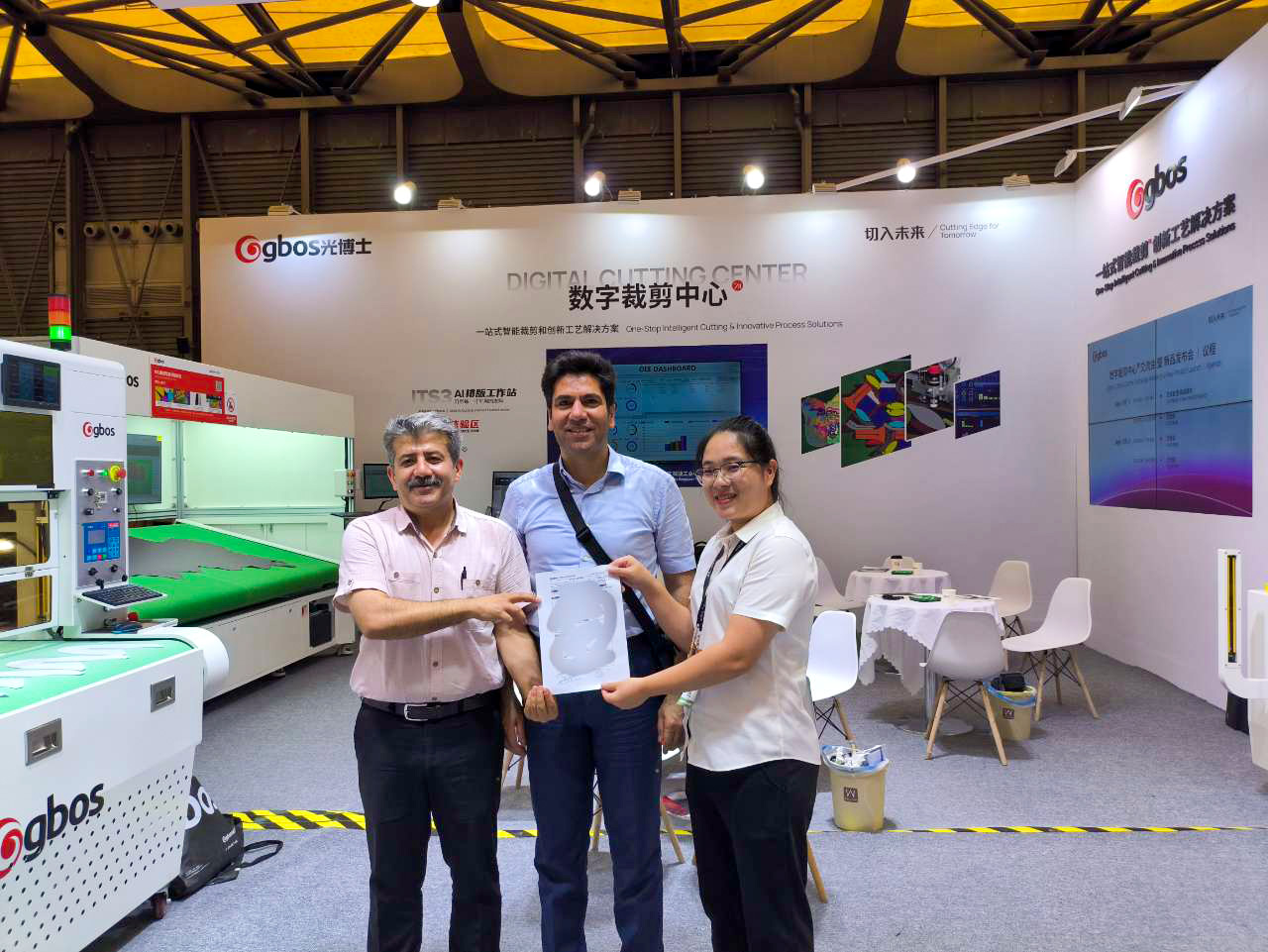

GBOS’s booth not only attracted domestic visitors but also garnered international interest.

One such example was a delegation from Iran, who expressed strong interest in GBOS’s products and services. After in-depth discussions, both parties swiftly reached a cooperation agreement, resulting in the successful on-site signing of multiple VC9-1660T units. This model, the sibling of the showcased VC9-1670T/N-4SCCD, specializes in the cutting and perforation of multi-layer footwear materials. By leveraging CAD software, it provides a more digitized and efficient production solution, significantly enhancing the precision and efficiency of footwear material processing.

This order from Iran not only highlights the high level of recognition for GBOS’s products and technology but also marks a key milestone in the company’s continued global expansion. Through such international collaborations, GBOS has reaffirmed its competitiveness and influence in the global leather and footwear industries.

3. Digital Leather Cutting Center: Leading the Future of Smart Manufacturing

The “Digital Cutting Center” solution showcased by GBOS integrates AI vision recognition and digital management systems, presenting visitors with a highly efficient, precise, and eco-friendly leather processing solution. This innovative approach not only boosts production efficiency and reduces costs but also supports the sustainable development of the leather industry.

As the All China Leather Exhibition (ACLE) concluded successfully, GBOS carries forward the momentum and confidence gained from the event, continuing to deepen its technological innovations and R&D investments in the leather processing sector. The company remains committed to its guiding principle of “Technology-Driven Development, Quality-Centered Market Leadership,” striving to become a global leader in leather processing. Looking ahead, GBOS will collaborate with more partners to promote the digital transformation and upgrade of the leather industry, working tirelessly toward a greener, smarter, and more efficient future for leather production!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: