The Saigon Fabric and Garment Accessories Expo 2022 in Vietnam came to a successful conclusion. It is reported that attracted nearly 20,000 visitors to the event for networking and learning. GBOS is also bringing its latest innovative process solutions to empower the textile industry at the show.

At the same time, the denim laser washing machine (XXP5-600-2D) has also received widespread attention. One denim washing machine can complete the one-stop denim laser dry process such as cat whiskers, PP scrap, grinding, damaging and fully printing, which solves the dependence of traditional denim manufacturing on manual labor. It is adapted to the S-Denim 6.0 software system developed specifically for the denim washing process and has a wide range of graphics at the touch of a button. Pay respects to traditional process with digitize, it helps the denim industry to achieve green production.

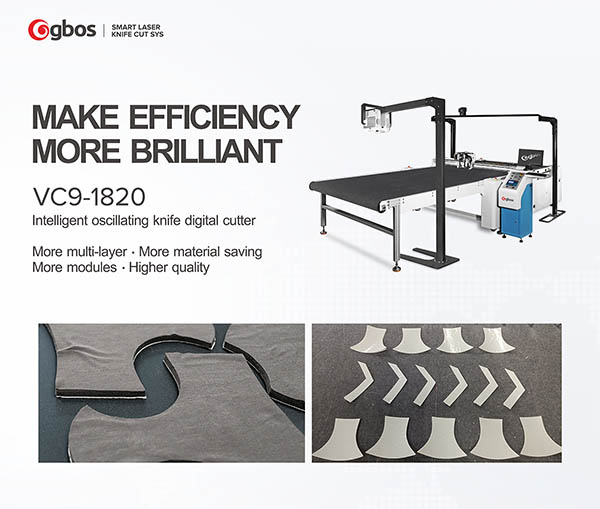

In addition to the laser process, the multifunctional multi-layer oscillating knife cutting system (VC9-1820) is also highly regarded. With the oscillating knife cutter you can digitally produce of new elastic fabrics with 15-20 layers and shorten the time-to-market by producing large or small diverse orders in a short period of time. It can also be equipped with different modules according to different needs, so that the same model can be used for different applications.

Always have insight into user needs and industry technology trends, Dedicated research and development, focused on innovation. It is the mission of GBOS to continuously provide professional technical support to the various flexible materials industries.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: