-

Mar 22, 2024

In 2023, BYD released a video titled “Together, We Are Chinese Cars,” which garnered widespread attention and enthusiastic response across the internet. This video not only serves as a declaration of the BYD brand but also symbolizes the confidence and determination of China’s new energy vehicle industry. It marks the shift towards new energy vehicles becoming a major trend for the Chinese automotive industry to compete globally, continuously leading into the future. The global promotion and development of new energy vehicles not only demonstrate advancements in new energy technology but also underscore the importance of precision manufacturing of various car components for automakers. Among these components, the manufacturing process of car seats is particularly crucial. When selecting seat suppliers, major automotive brands follow a set of evaluation criteria, preferring suppliers who can provide comprehensive solutions, demonstrate excellent environmental records, and possess innovative capabilities. These criteria include meeting standards in cutting processes, effectively saving leather materials to enhance cost-effectiveness, and other key indicators, all aimed at providing consumers with the ultimate comfort experience. However, manufacturers are confronted with challenges...

In 2023, BYD released a video titled “Together, We Are Chinese Cars,” which garnered widespread attention and enthusiastic response across the internet. This video not only serves as a declaration of the BYD brand but also symbolizes the confidence and determination of China’s new energy vehicle industry. It marks the shift towards new energy vehicles becoming a major trend for the Chinese automotive industry to compete globally, continuously leading into the future. The global promotion and development of new energy vehicles not only demonstrate advancements in new energy technology but also underscore the importance of precision manufacturing of various car components for automakers. Among these components, the manufacturing process of car seats is particularly crucial. When selecting seat suppliers, major automotive brands follow a set of evaluation criteria, preferring suppliers who can provide comprehensive solutions, demonstrate excellent environmental records, and possess innovative capabilities. These criteria include meeting standards in cutting processes, effectively saving leather materials to enhance cost-effectiveness, and other key indicators, all aimed at providing consumers with the ultimate comfort experience. However, manufacturers are confronted with challenges... -

Mar 16, 2024

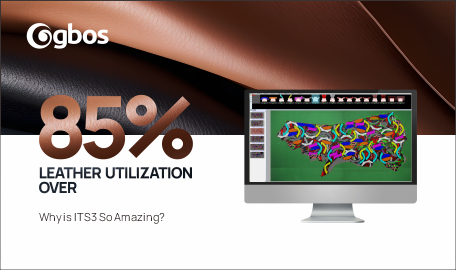

![Small Batch& Customized–Leather Sofa [One-stop] Intelligent Nesting + Cutting Small Batch& Customized–Leather Sofa [One-stop] Intelligent Nesting + Cutting](https://www.gboslaser.com/wp-content/uploads/2024/03/2024031611520755fd2.jpg) “As the rigid demand for living space grows among the younger generation, the demand for furniture catering to small spaces, cost-effectiveness, and integrated design is increasing. This trend, coupled with increasingly stringent environmental standards set by the government, is pushing leather furniture manufacturers to transition towards digitization and green manufacturing, aiming for dual optimization of cost-effectiveness.” 01 Leather Nesting and Cutting: Manual vs. Automated Traditionally, crafting a standard leather sofa requires nesting and cutting different sizes and qualities of leather for various parts of the sofa. During this process, craftsmen face challenges such as material displacement and wastage through manual nesting and cutting. This method not only lacks efficiency but also results in low material utilization. Additionally, it’s difficult to transfer such skills, leading to challenges in finding experienced craftsmen. In contrast, employing digital equipment for nesting centralizes data processing and swiftly provides multiple nesting schemes through cloud computing analysis, significantly reducing material wastage and achieving efficient cutting. This integrated solution of nesting and cutting saves considerable time, labor costs, and boosts leather utilization rates to 85% or higher. Moreover, the nesting equipment seamlessly connects with cutting equipment, achieving nesting + cutting in one step, saving...

“As the rigid demand for living space grows among the younger generation, the demand for furniture catering to small spaces, cost-effectiveness, and integrated design is increasing. This trend, coupled with increasingly stringent environmental standards set by the government, is pushing leather furniture manufacturers to transition towards digitization and green manufacturing, aiming for dual optimization of cost-effectiveness.” 01 Leather Nesting and Cutting: Manual vs. Automated Traditionally, crafting a standard leather sofa requires nesting and cutting different sizes and qualities of leather for various parts of the sofa. During this process, craftsmen face challenges such as material displacement and wastage through manual nesting and cutting. This method not only lacks efficiency but also results in low material utilization. Additionally, it’s difficult to transfer such skills, leading to challenges in finding experienced craftsmen. In contrast, employing digital equipment for nesting centralizes data processing and swiftly provides multiple nesting schemes through cloud computing analysis, significantly reducing material wastage and achieving efficient cutting. This integrated solution of nesting and cutting saves considerable time, labor costs, and boosts leather utilization rates to 85% or higher. Moreover, the nesting equipment seamlessly connects with cutting equipment, achieving nesting + cutting in one step, saving...

-

More DetailsFeb 08, 2023Current market situation of footwear industry Since the outbreak of Newcastle Pneumonia, the global economy has been hit hard, and the footwear industry is also facing a huge test. Although the footwear industry in China continues to grow, reports show that global footwear consumption will decrease by an average of 22.5% in 2021, with Europe down 27%, North America down 21% and Asia down 20%. The market operating environment of the footwear industry is extremely severe, and practitioners are facing tremendous pressure and challenges. Equipment optimization, poised for growth In the face of unstable market growth, companies face many challenges: On the one hand, the industry is aiming for internationalization and market globalization, and on the other hand, the traditional footwear industry is facing problems such as high labor costs and uneven quality of production. In addition, the ever-changing market demand requires companies to produce and deliver orders faster and more efficiently, putting higher demands on the shoe supply chain system. Companies must re-examine themselves to adapt to the changing demand conditions. For example, replacing manual labor or outdated machines with advanced equipment, thus increasing productivity and significantly improving productivity. A way to transform your production floor into a profit...

-

More DetailsFeb 08, 2023August 17th, a notice was published, Among them, to create a number of “small, fast, light and accurate” digital system solutions and to create 4,000-6,000 “small lighthouse” enterprises as digital transformation benchmark enterprises, is the notice pointed out in the manufacturing industry important guidance direction. Among them, the textile, clothing and leather products processing for the transformation of one of the pilot sub-sectors. The future of manufacturing: small, fast, light and accurate. The development of the manufacturing industry is the cornerstone of the development of the real economy. The development of the manufacturing industry in terms of miniaturisation, speed, lightness and precision is the top priority of the development of the digital economy, and the deep integration of the digital economy with the real economy is a favourable choice for achieving high-quality development. However, the traditional manufacturing model has brought many challenges to the digital development of the manufacturing industry, taking the processing of textile, garment and leather industries as an example: high labour costs, time-consuming processes and high energy consumption are among the many problems that arise. In order to actively respond to the national policy, as well as to effectively solve the traditional manufacturing industry pain points, GBOS...

-

More DetailsFeb 08, 20232015, Launch three-axis laser cutting machine. 2017, Launch four-axis laser cutting machine. 2019, Launch five-axis laser cutting machine. (and delivery the first 3D five-axis laser cutting machine in the same year) The breakthrough of GBOS’s 3D five-axis technology not only represents a better process application for users, but also brings undeniable power to promote the development of the industry. As an innovative product applied to the non-metallic field, it has shown many excellent advantages and highlights in helping various industries to transform and upgrade. In the process of processing, no moulds are required, thus reducing the cost of mould opening and mould management; secondly, the application of trimming and cutting holes for various shaped and 3D curved products greatly improves production efficiency. As the level of intelligent continues to rise, the 3D complex surface laser cutting process has also continued to make breakthroughs and is now successfully used in small/large batch manufacturing in industries such as automotive, aerospace, lighting, luggage and lingerie. It enables the trimming and punching of shaped edges and holes for automotive interior injection moulded parts, car lamp spouts and luggage blister parts, greatly increasing the efficiency of the production process and producing products with smooth and...

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: