On this Arbor Day, a day of advocating for greenery and spreading hope, GBOS remains committed to the ESG (Environmental, Social, and Governance) principles, driving green transformation in manufacturing through technological innovation and contributing to the sustainable development of our planet.

PART 01 Intelligent Nesting: The “Smart Brain” of Material Utilization

PART 01 Intelligent Nesting: The “Smart Brain” of Material Utilization

When it comes to material savings, GBOS’s ITS rule-based nesting system and ITS2/ITS3 AI intelligent leather nesting system play a crucial role. By leveraging advanced algorithms for precise calculations, they optimize material usage before production begins. This helps customers reduce material costs, prevent inventory buildup, and maximize the value of every piece of material, enhancing overall resource utilization.

PART 02 Lean Smart Manufacturing: The “Green Responsibility” for Energy Efficiency and Longevity

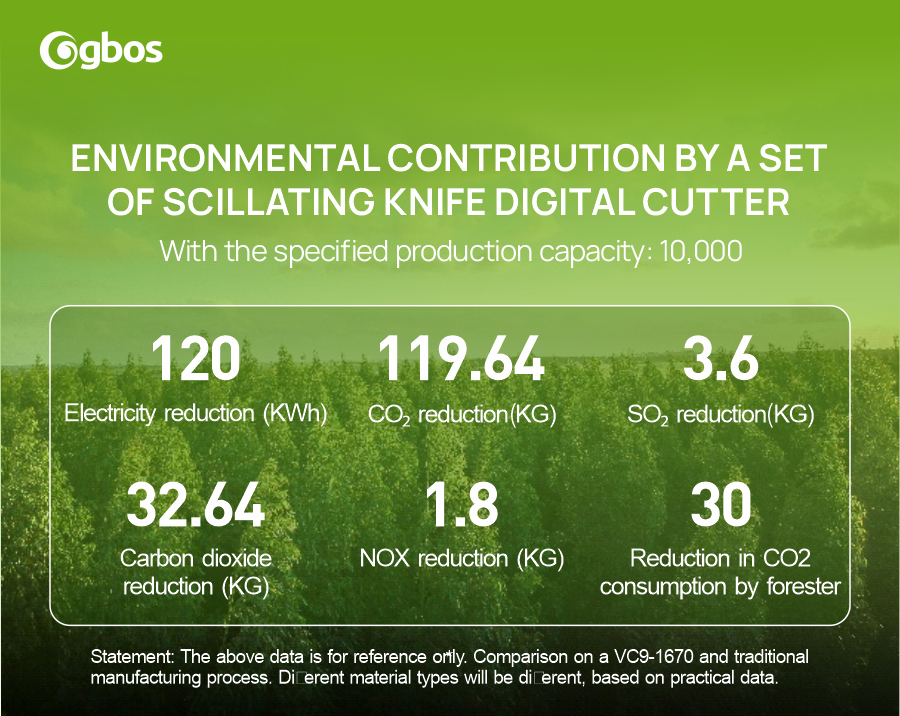

GBOS machines excel in resource and energy efficiency, with a lifespan of up to 20 years, significantly reducing resource consumption caused by equipment replacement. Take the next-generation digital cutting center as an example—it integrates advanced digital technology to precisely regulate power distribution, eliminating waste and maximizing energy utilization. This reduces energy consumption and carbon emissions, supporting carbon neutrality goals and contributing to global climate change mitigation.

PART 03 Green Innovation: The “Low-Carbon Pioneer” of Denim Washing

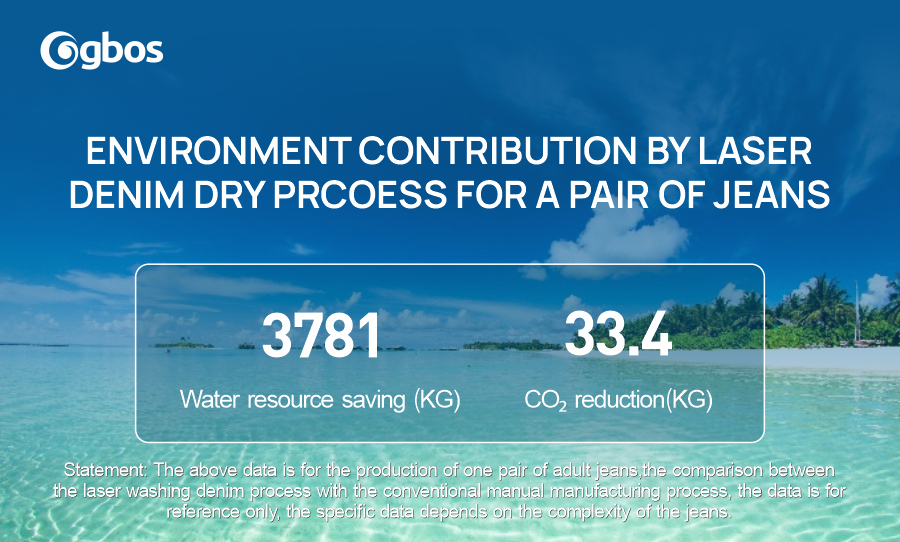

GBOS S-Denim 6.0 system, powered by cutting-edge innovation, sets a new green benchmark for the denim washing industry. Through intelligent process optimization, it significantly reduces water and chemical usage, enhancing production efficiency while achieving a major breakthrough in environmental performance. This revolutionary advancement brings denim manufacturing closer to nature, positioning it as a “low-carbon pioneer” driving the industry’s green transformation and contributing to the protection of our natural ecosystem.

PART 04: Process Optimization: The “Accelerator” of Green Production

The IoT Bridge system, independently developed by GBOS, serves as an intelligent manufacturing accelerator in the era of Industry 4.0, fully empowering enterprise process optimization and digital transformation. This system not only enables seamless connectivity for the brand’s proprietary equipment but also supports third-party devices and integrates with multi-dimensional management systems such as MES, ERP, OA, CAD, and PLM, creating a comprehensive intelligent manufacturing ecosystem.

Thanks to the IoT Bridge, users can implement paperless production while effectively recording production data, driving the visualization of production line data. It provides a traceability basis for production, helping businesses identify and resolve issues, as well as optimize their strategic direction.

Arbor Day, an eternal symbol of green action, carries humanity’s beautiful aspirations for sustainable development. GBOS has long integrated green sustainability into its brand DNA, guided by ESG principles and driven by technological innovation, continuously leading the manufacturing industry toward a green transformation.

In the future, we will continue to work hand in hand with industry partners to build a new ecosystem for green manufacturing and contribute to the sustainable future of the Earth.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: