Origin of Outdoor Jackets

Outdoor jackets originated from Western polar expeditions and have long been the trusted companion of outdoor adventurers. Initially designed to withstand harsh natural environments, they gradually evolved from specialized outdoor gear into a darling of the fashion world.

The Role of Outdoor Jackets in Modern Society

From essential outdoor gear to a must-have fashion item for daily wear, and now an indispensable part of the Citywalk commuter wardrobe, outdoor jackets have gained favor among consumers both domestically and internationally for their unique design and practicality. Not only do they meet the functional needs of outdoor activities, but they have also become an important means for urban youth to express their personal style.

Challenges Facing Outdoor Jacket Brands

As the market expands and consumer demands diversify, outdoor jacket brands face significant challenges. How to stay ahead in a competitive market and how to convert consumer enthusiasm into brand loyalty are pressing issues that manufacturers need to address.

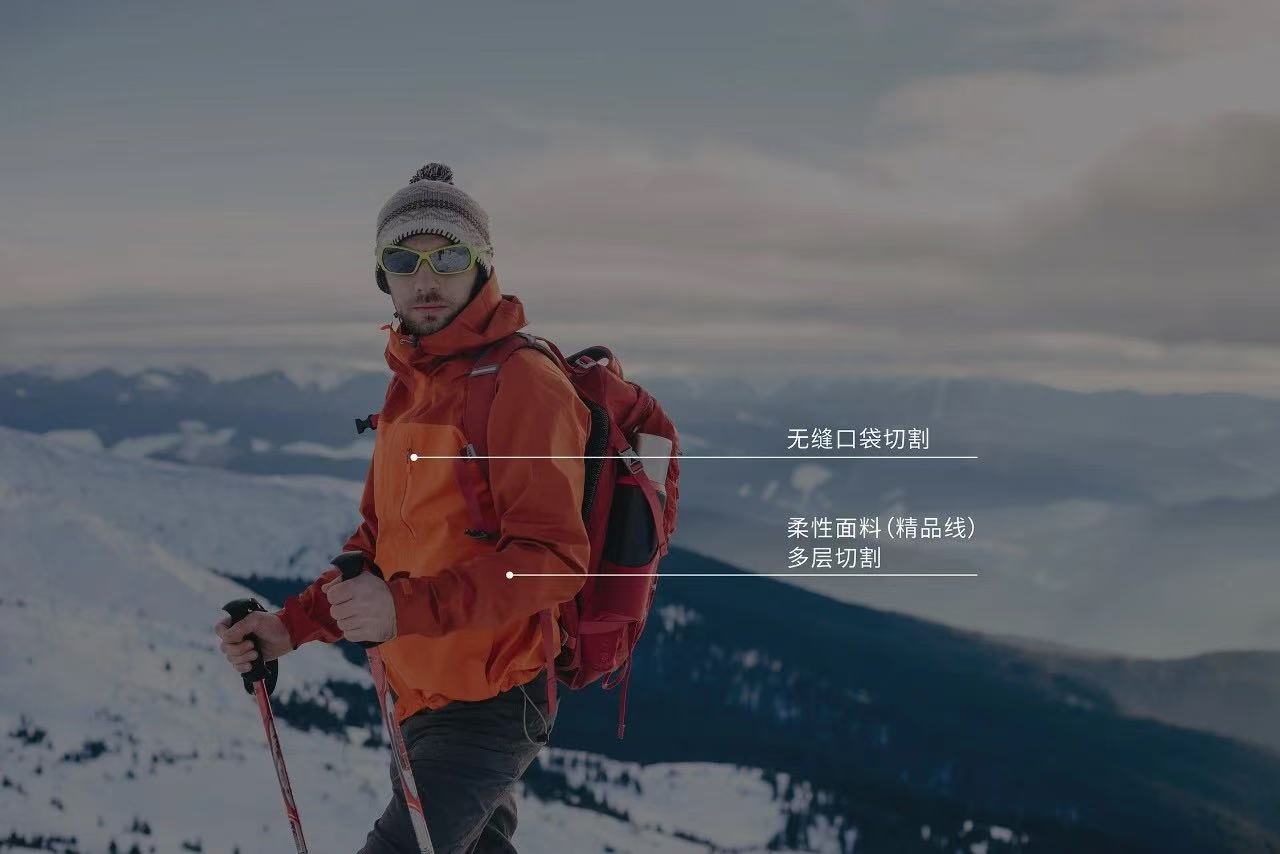

Breakthroughs in Fabric Cutting Technology

In the field of fabric cutting, the VC9-1616TT oscillating knife cutting machine provides manufacturers with efficient and precise solutions. It uses automatic high-frequency oscilation technology, allowing for fast and accurate cutting of flexible materials while reducing material waste. Without the need for a knife mold, it saves both costs and time, reduces reliance on manual operations, and lowers error rates. Additionally, the oscillating knife cutting machine is environmentally friendly, capable of cutting new high-tech fabrics.

In terms of seamless pocket craftsmanship, the GNM1280T laser cutting seamless tape technology brings revolutionary changes. Laser cutting produces narrow, smooth cuts, reducing the need for stitching and lowering labor intensity. It enhances the aesthetic appeal and functionality of finished products, making the details of outdoor jackets more refined. Moreover, the small heat-affected zone during laser cutting helps preserve the properties of the materials, preventing issues such as melting, scorching, or yellowing edges. Laser cutting technology also demonstrates environmental and sustainability advantages by reducing material waste and minimizing environmental impact.

Strategies for Manufacturers

For manufacturers, seizing the “billion-dollar opportunity” during the golden era of outdoor jackets means capturing market opportunities and continuously innovating in craftsmanship to meet consumer demands. By adopting advanced technological processes, they can improve production efficiency, lower costs, and reduce environmental impact. This approach helps enhance brand image, maintain a competitive edge in the market, and ensure that outdoor jackets continue to advance on the path of both fashion and functionality.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: