Stock Code: 870145

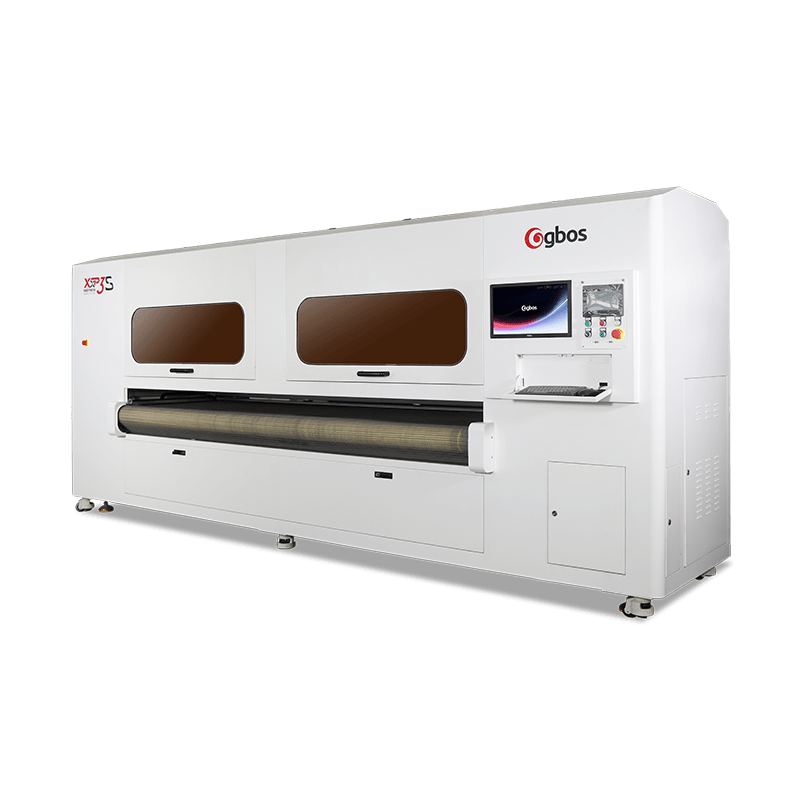

XXP3S Series

Automatic Feeding Laser Marking system

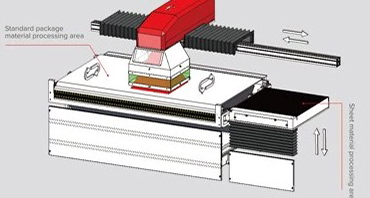

It is suitable for processing whole rolls of synthetic materials or fabrics. The software is convenient for typesetting, and realizes continuous and uninterrupted automatic feeding and processing of whole rolls of materials. At the same time, it has a fixed processing area to meet the use scenarios of sheet materials and proofing.

Software is compatible with both working tables.

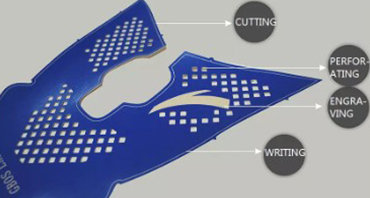

One time finish multi processing (perforation, engraving, cutting, marking).

Special design - the only one in Asia. Enclosed injection molding, more stable.

Equipped with three exhausters to increase the air flow, ensuring good marking effect.

Combined all capabilities of 11 machine (10 laser cutting machine + 1 laser marking machine).

Batch production, save labor cost, reduce material waste, save time, increase working efficiency.

Fixed table on right side (XXP3 model) is convenient for sample making during mass production.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

Double Working Table① Auto-feeding table for material in roll, for mass production, working area is 1600*400mm. ② Fixed working table for material in piece. Adjustable working area: 400*400mm - 500*500mm - 600*600mm.

Double Working Table① Auto-feeding table for material in roll, for mass production, working area is 1600*400mm. ② Fixed working table for material in piece. Adjustable working area: 400*400mm - 500*500mm - 600*600mm. -

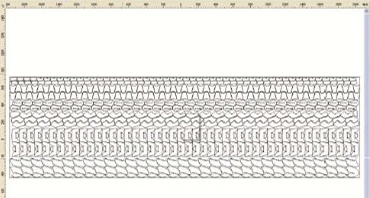

Smart Nesting SoftwareUltra-length smart Stitching + unlimited length nesting.

Smart Nesting SoftwareUltra-length smart Stitching + unlimited length nesting. -

One Time Completed Multiple ProcessesOne time finish roll leather engraving, writing, perforation and cutting.

One Time Completed Multiple ProcessesOne time finish roll leather engraving, writing, perforation and cutting. -

Fast Speed and High Efficiency① With 3D dynamic scan head. ② About 15% faster than competitors. ③ About 10 times faster than laser cutting machine.

Fast Speed and High Efficiency① With 3D dynamic scan head. ② About 15% faster than competitors. ③ About 10 times faster than laser cutting machine. -

Intelligent Lift PlatformFixed working table can be manually raised or lowered to adjust the working area.

Intelligent Lift PlatformFixed working table can be manually raised or lowered to adjust the working area. -

Safety Design for SyntheticWhole machine adopt the fully enclosed design, it is more safety for the operator. And better effect to catch the smoke.

Safety Design for SyntheticWhole machine adopt the fully enclosed design, it is more safety for the operator. And better effect to catch the smoke.

Expand More +

Functions & Modules

-

Purify and treat the smoke and waste gas generated during the cutting processMore Details

Purify and treat the smoke and waste gas generated during the cutting processMore Details -

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details

Expand More +

Industry Solutions

-

Garment Accessories Industry

-

Leather Goods

-

Automotive Interior Industry

-

Footwear Industry

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: