Stock Code: 870145

DP Series

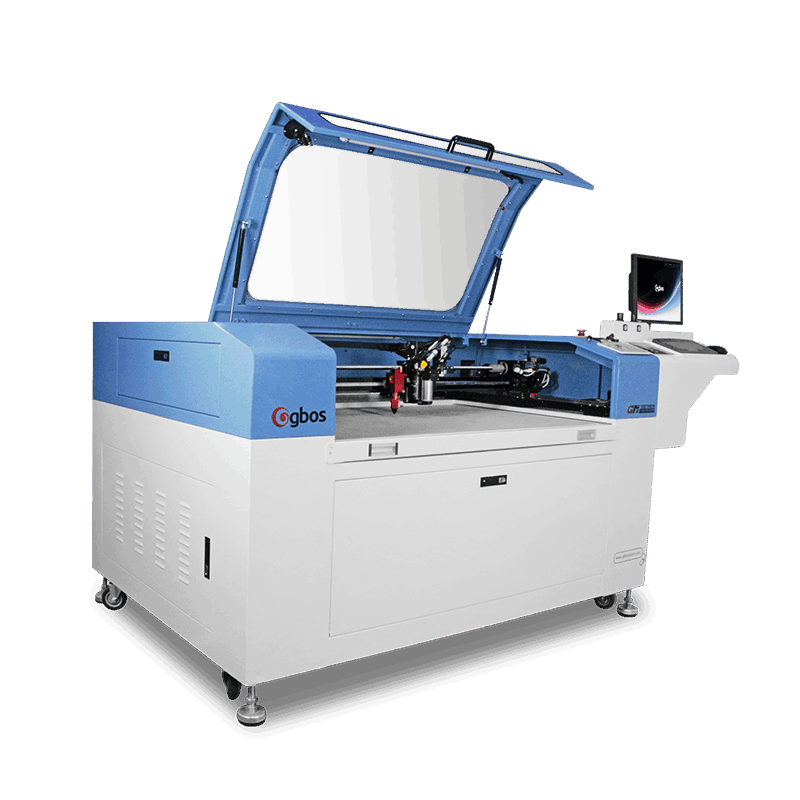

DP series Sewfree® Seamless PUR Dispensing System

Innovative seamless process, providing a more comfortable wearing experience. Explore more innovative processes with integrated laser cutting function.

It is the first choice for sewfree® artwork.

It can realize automatic operation of cutting and dispensing, saving labor and material costs.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

Independent PUR Dispensing SystemFirst choice for seamless artworks.

Independent PUR Dispensing SystemFirst choice for seamless artworks. -

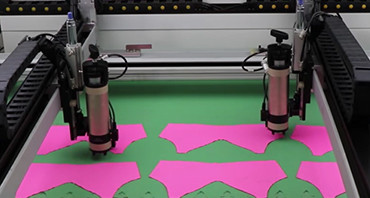

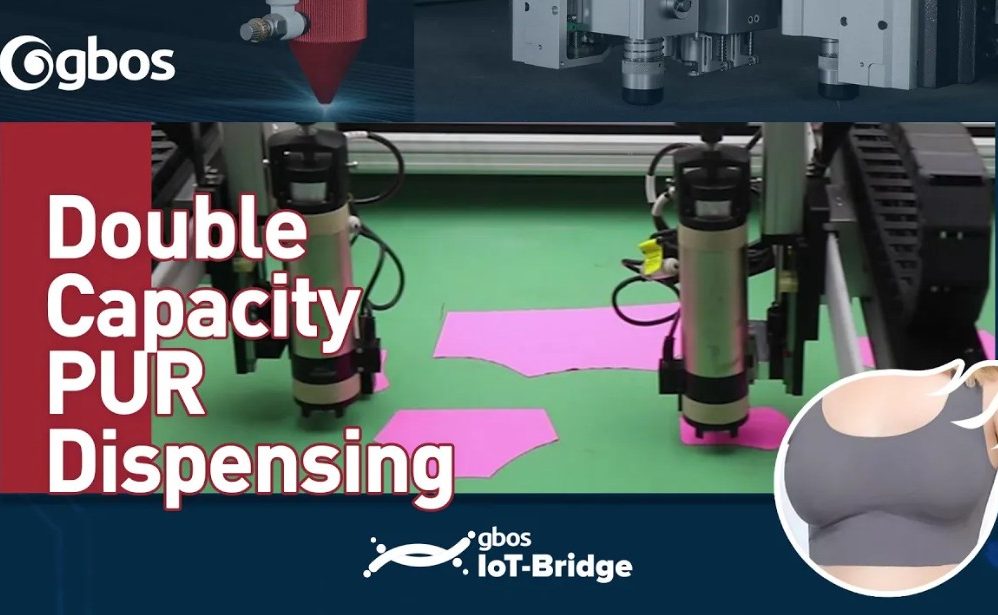

Multiple Templates and Patterns Processing at the Same TimeFeature contour extraction dispensing, arbitrary placement of different graphic files. No requirements for the operators.

Multiple Templates and Patterns Processing at the Same TimeFeature contour extraction dispensing, arbitrary placement of different graphic files. No requirements for the operators. -

Co-existence Quality and EfficiencyLess sewing, sorting cost; Less machinery, space cost; and less management cost create more stretchable and flexible seamless garment and no yellow, no black, no burnt.

Co-existence Quality and EfficiencyLess sewing, sorting cost; Less machinery, space cost; and less management cost create more stretchable and flexible seamless garment and no yellow, no black, no burnt. -

Reduce Process, More Environmentally Friendly and Economically EfficientPUR Dispensing+Positioning and cutting+Heat press+Completely cured after 72 hours.

Reduce Process, More Environmentally Friendly and Economically EfficientPUR Dispensing+Positioning and cutting+Heat press+Completely cured after 72 hours. -

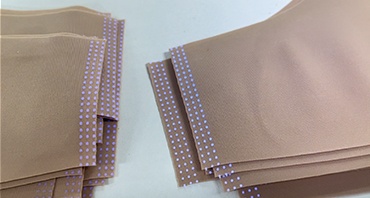

Newest PUR Seamless Dispensing DevicePUR Dispensing without burrs, controllable distance, adjustable glue dots size. Glue dots size consistency, precision up to 98%.

Newest PUR Seamless Dispensing DevicePUR Dispensing without burrs, controllable distance, adjustable glue dots size. Glue dots size consistency, precision up to 98%. -

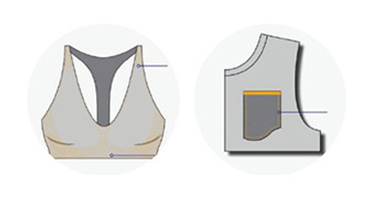

Light as a Cloud, Wear it SenselesslyUltra-comfortable PUR dispensing process: Trackless and comfortable, replace stitching, smooth and comfortable, the preferred process for sportswear.

Light as a Cloud, Wear it SenselesslyUltra-comfortable PUR dispensing process: Trackless and comfortable, replace stitching, smooth and comfortable, the preferred process for sportswear. -

FashionFully integrated fashion and function, meet the needs of all users in time.

FashionFully integrated fashion and function, meet the needs of all users in time. -

Low Bonding Temperature, Reduce Damage to FabricsHeat press temperature: 60-70℃; Heat press time: 10-15s.

Low Bonding Temperature, Reduce Damage to FabricsHeat press temperature: 60-70℃; Heat press time: 10-15s. -

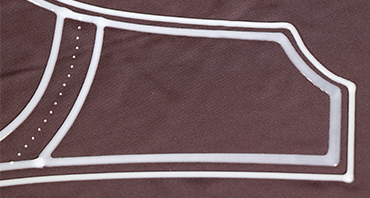

Create More Ideas with the Application Scenarios You WantMulti-Scene application: Pant Gusset; Necklines; Overlap Seams; Patch-On Pockets; Fold Over Hems; Compression Panels; Heat Sensitivity; Panel-to-Panel Bonding.

Create More Ideas with the Application Scenarios You WantMulti-Scene application: Pant Gusset; Necklines; Overlap Seams; Patch-On Pockets; Fold Over Hems; Compression Panels; Heat Sensitivity; Panel-to-Panel Bonding.

Expand More +

Functions & Modules

-

Non sewing dispensing can achieve reducing process steps, more environmentally friendly and energy saving. And it is easily adjust to different application.More Details

Non sewing dispensing can achieve reducing process steps, more environmentally friendly and energy saving. And it is easily adjust to different application.More Details -

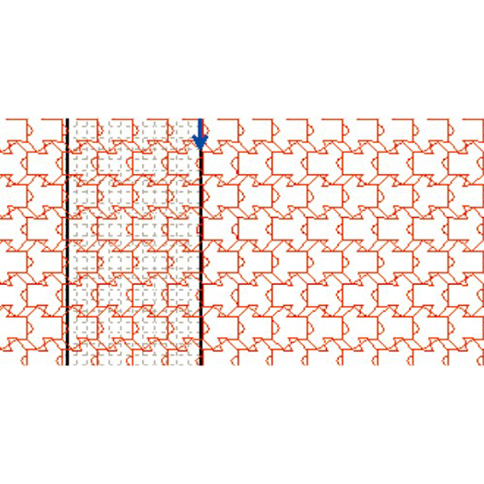

Intelligent nesting system, which is used for regular materials and can improve utilization and reduce material waste.More Details

Intelligent nesting system, which is used for regular materials and can improve utilization and reduce material waste.More Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: