Stock Code: 870145

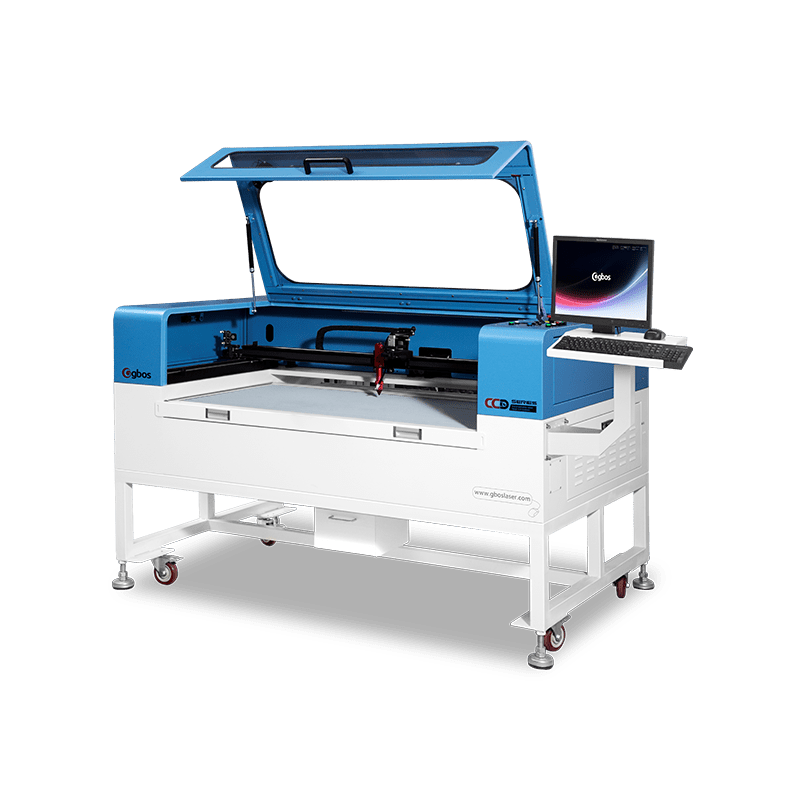

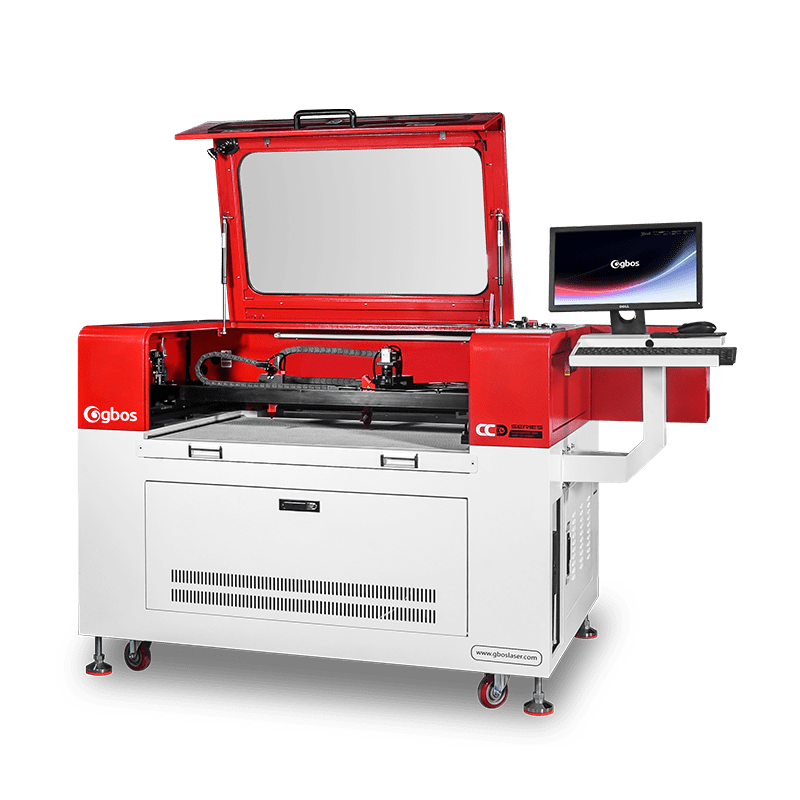

CCD Series

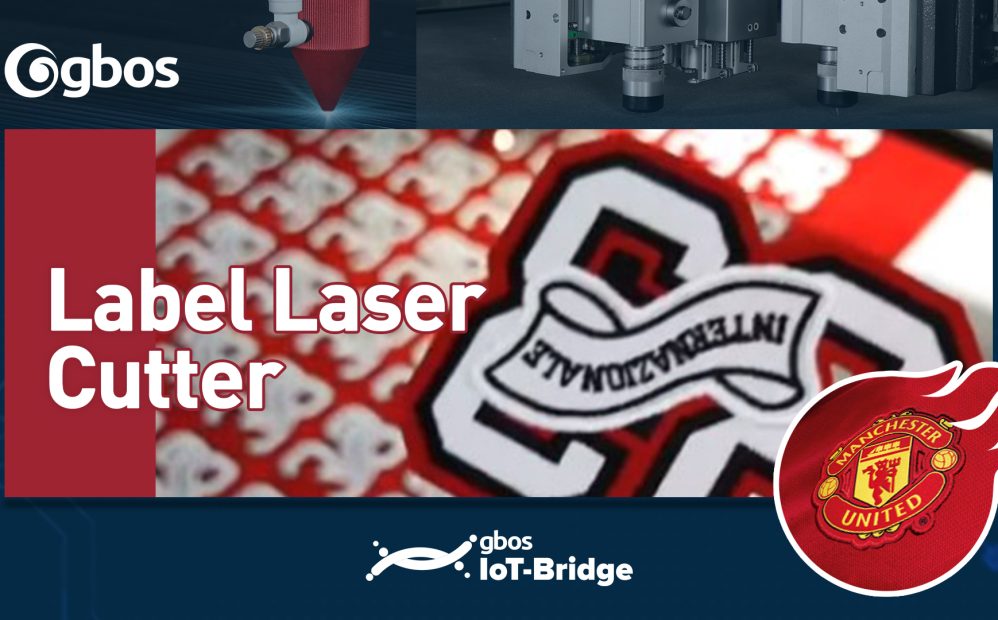

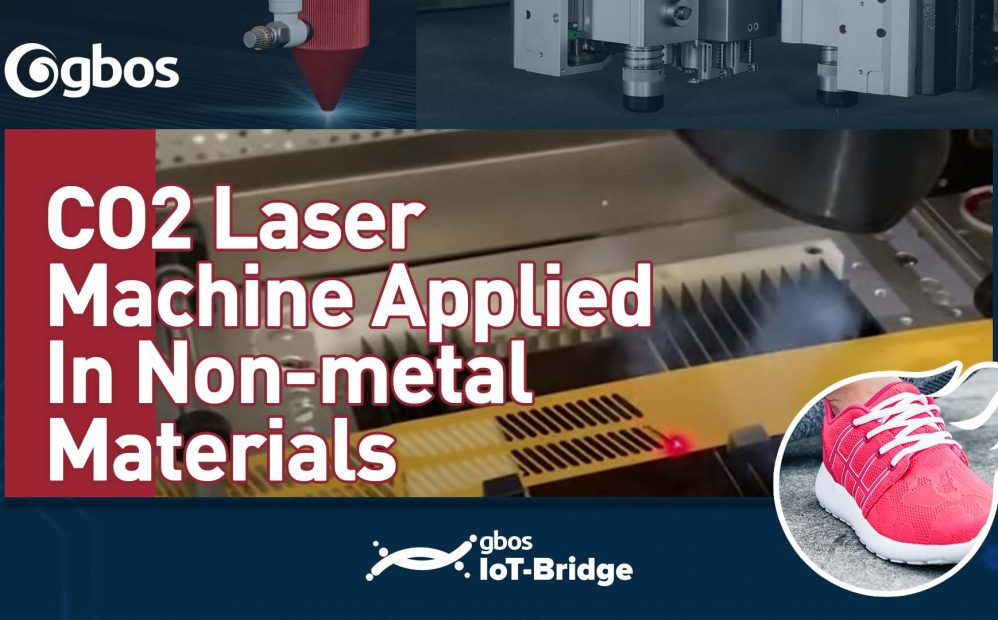

AI VisionScan & Positioning CO2 Laser Cutting Machine

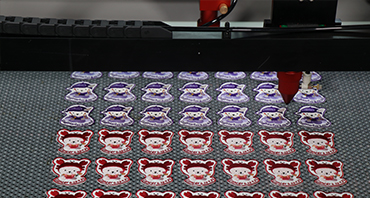

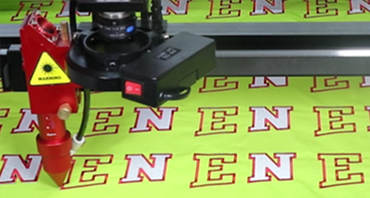

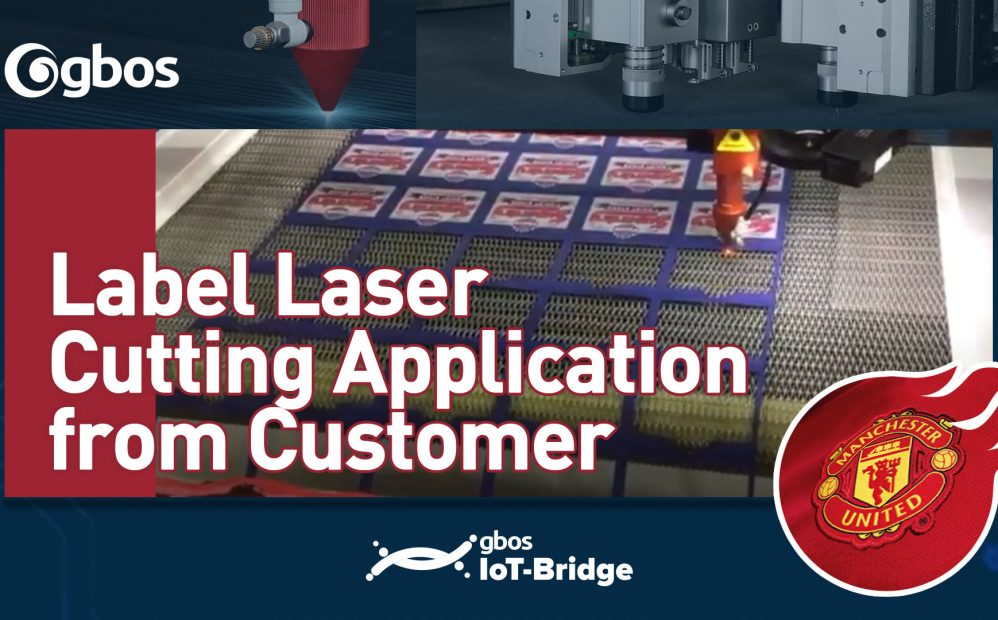

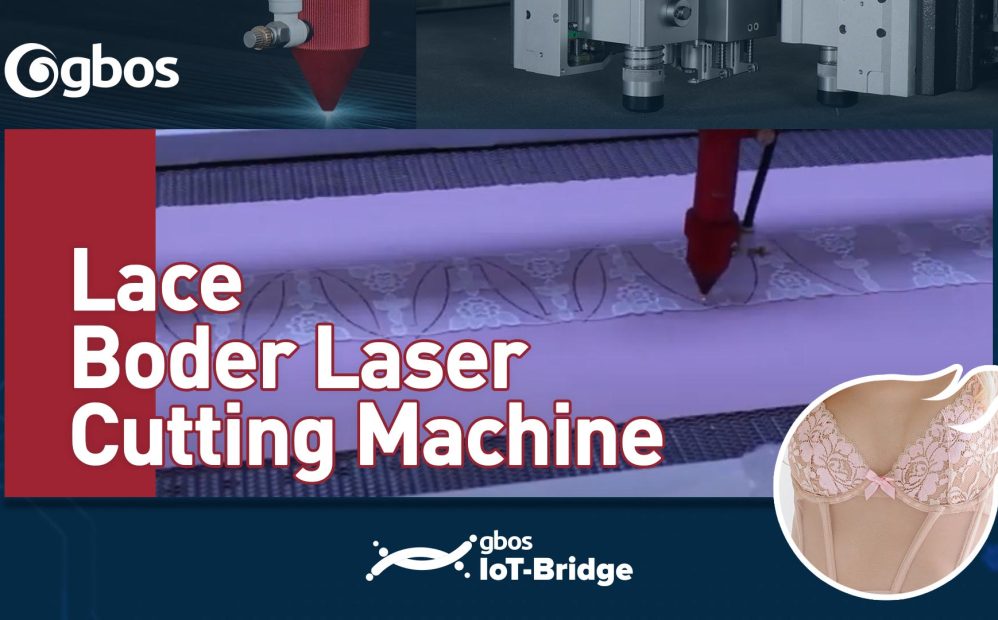

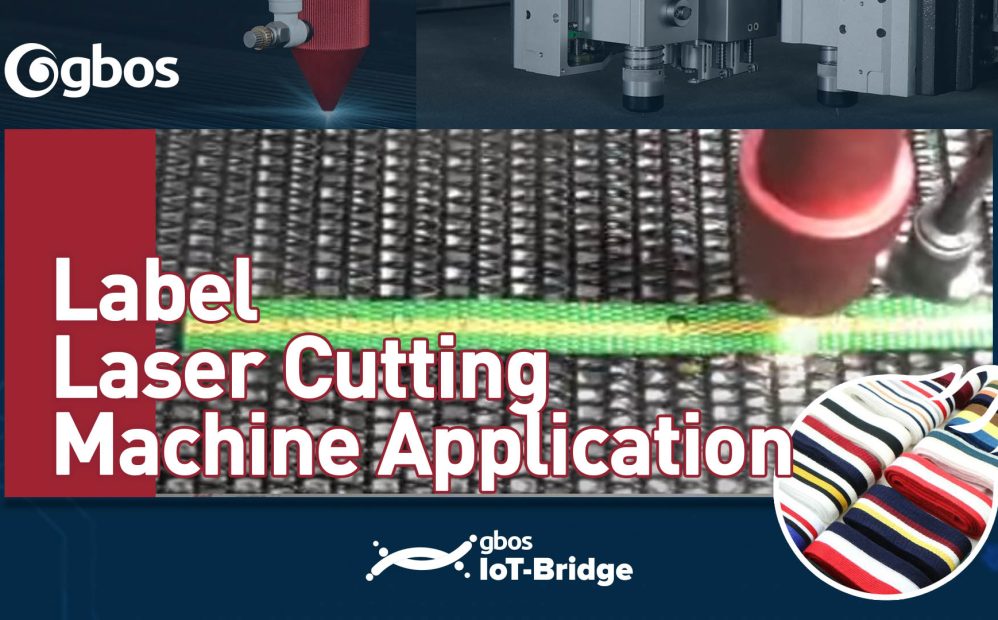

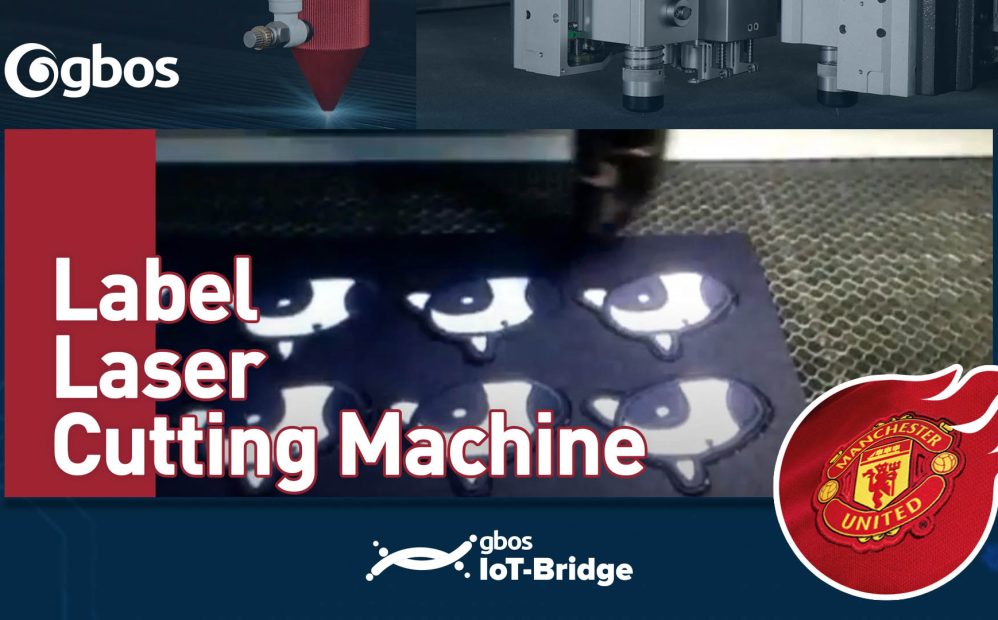

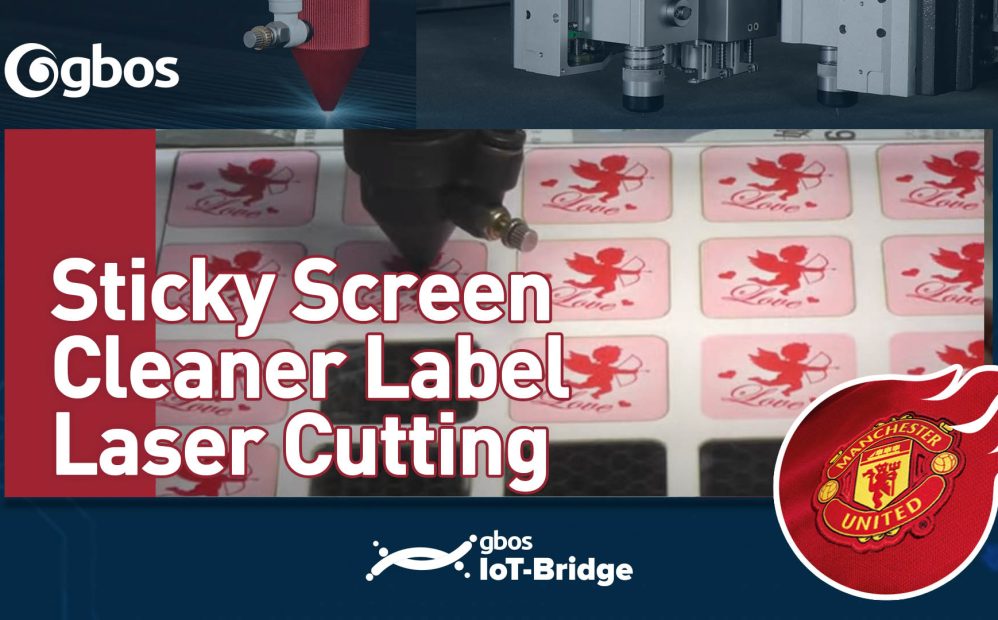

The camera quickly captures the outline of the label for precise cutting. The software automatically identifies unqualified products and cuts without burnt edges or yellow edges. Any angle of label is possible.

Edge reading & cutting (5.0).

Automatically identitying defect.

Full auto feeding device(optional).

Multi pattern, any angle positioning and cutting.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

Precise and Intelligence CuttingPositioning accuracy of 0.1mm, the best in the industry. Defective products can be selected.

Precise and Intelligence CuttingPositioning accuracy of 0.1mm, the best in the industry. Defective products can be selected. -

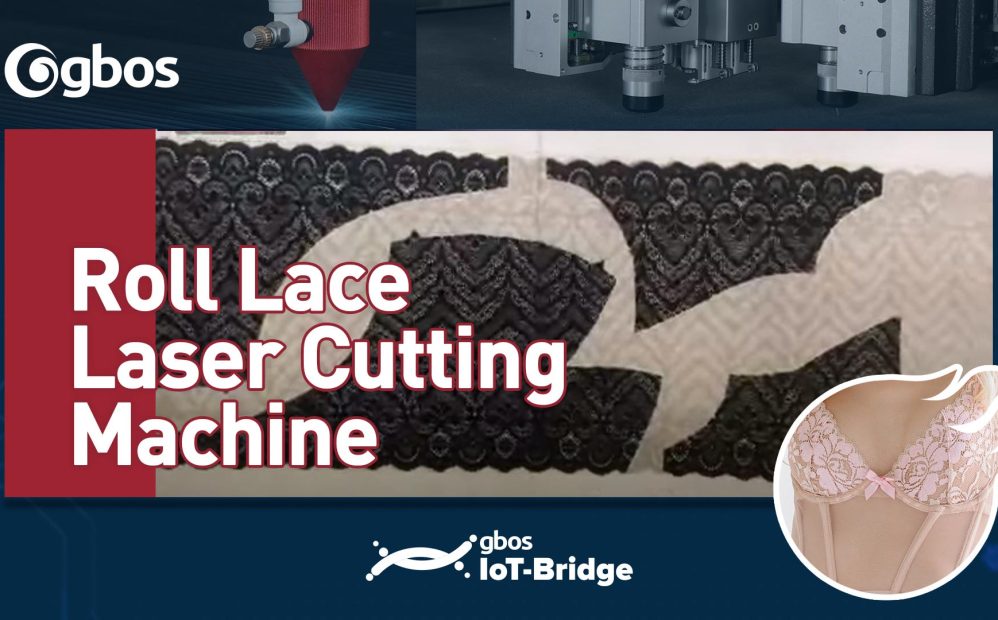

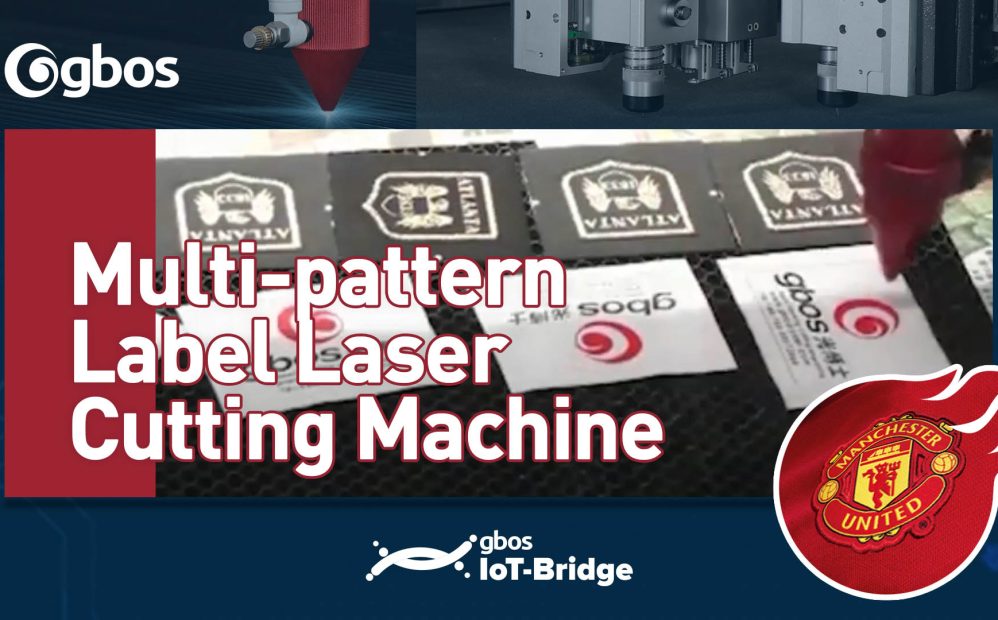

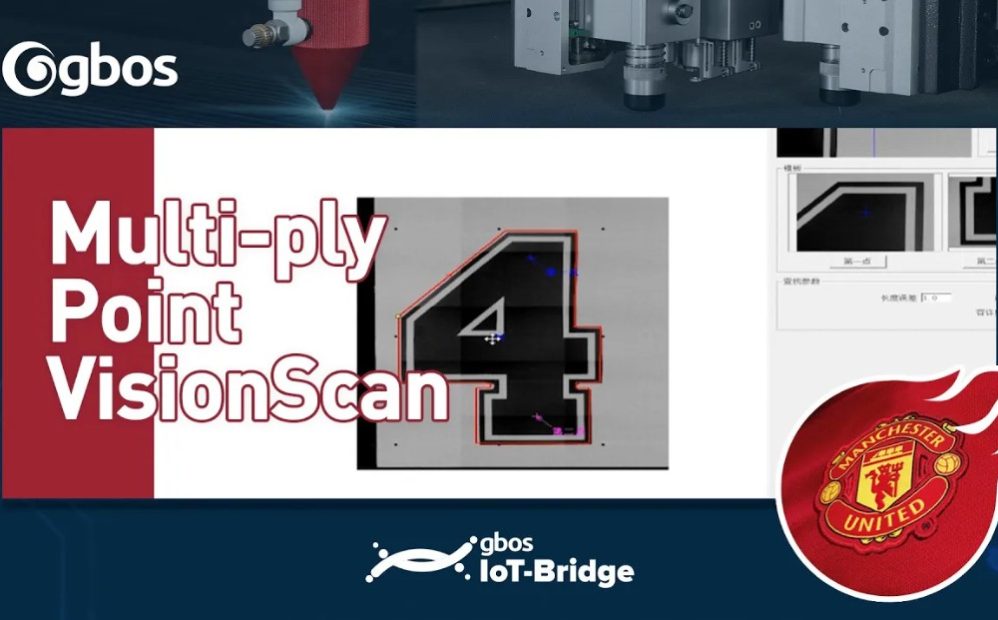

Positioning Cutting for Multiple DesignCut different labels at the same time to meet the needs of different products. Save time and improving work efficiently.

Positioning Cutting for Multiple DesignCut different labels at the same time to meet the needs of different products. Save time and improving work efficiently. -

SCCD Large size automatic extraction(Optional)① Effectively identify area: 850mm*600mm. ② One time recognized all label on the working table. ③ Increased camera area, overall automatic extraction and cutting. ④ Solve the problem that large labels cannot be automatically extracted.

SCCD Large size automatic extraction(Optional)① Effectively identify area: 850mm*600mm. ② One time recognized all label on the working table. ③ Increased camera area, overall automatic extraction and cutting. ④ Solve the problem that large labels cannot be automatically extracted. -

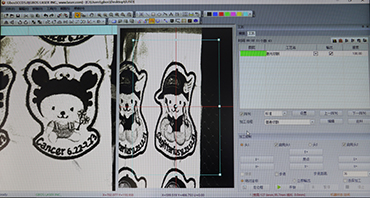

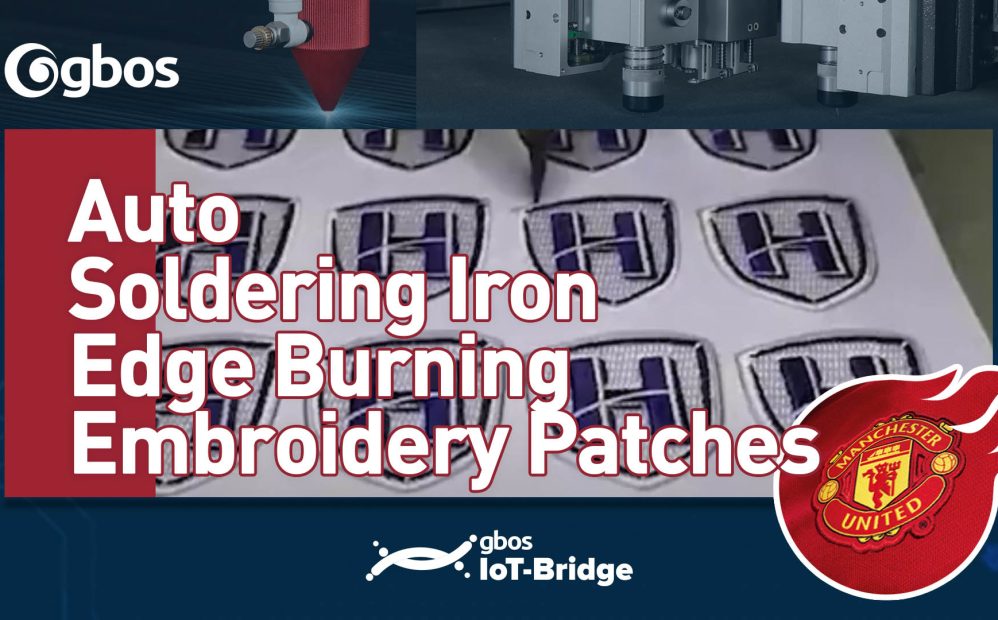

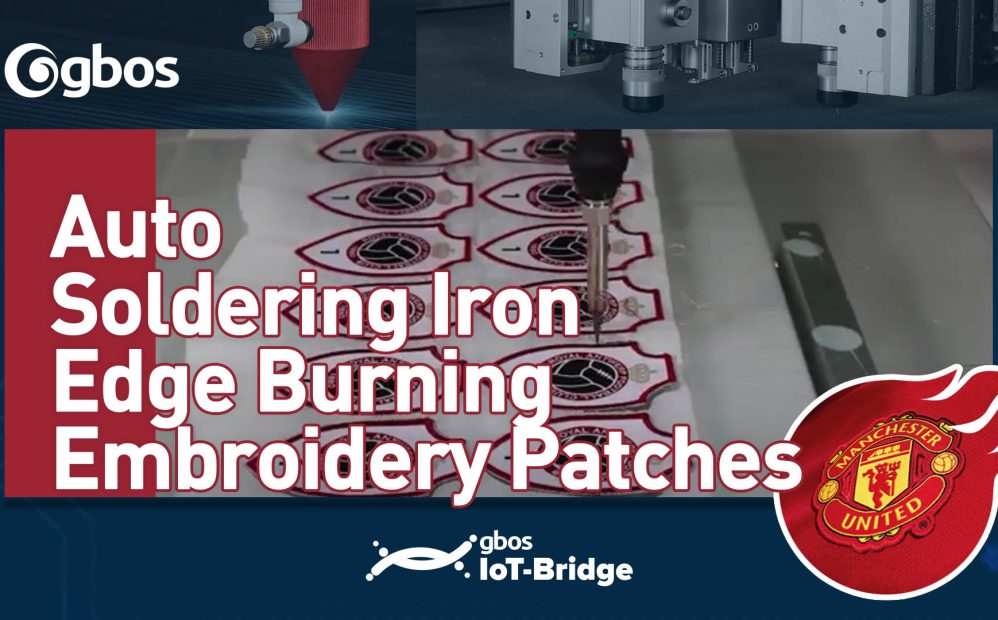

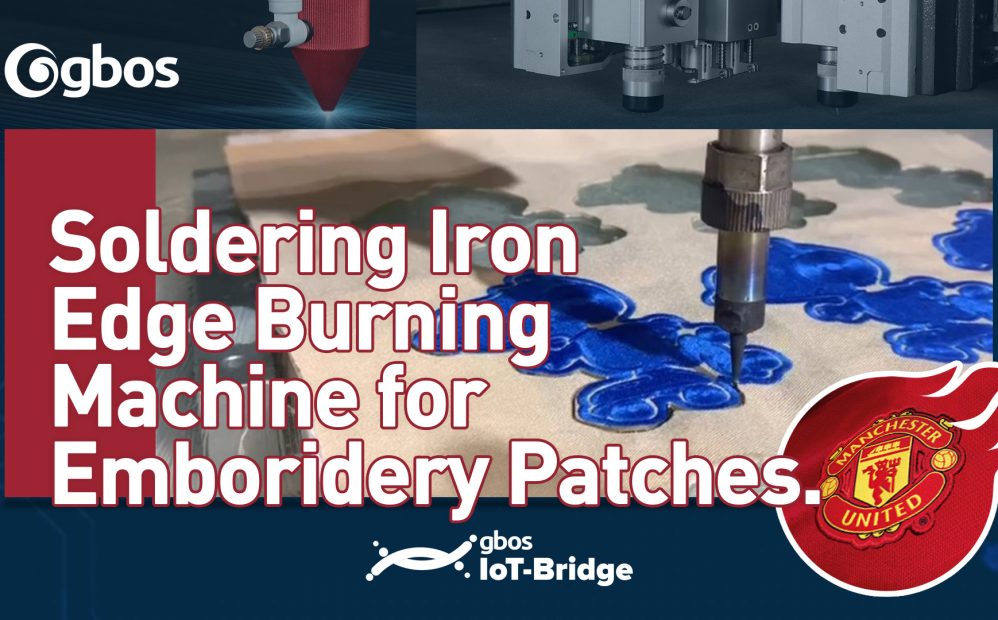

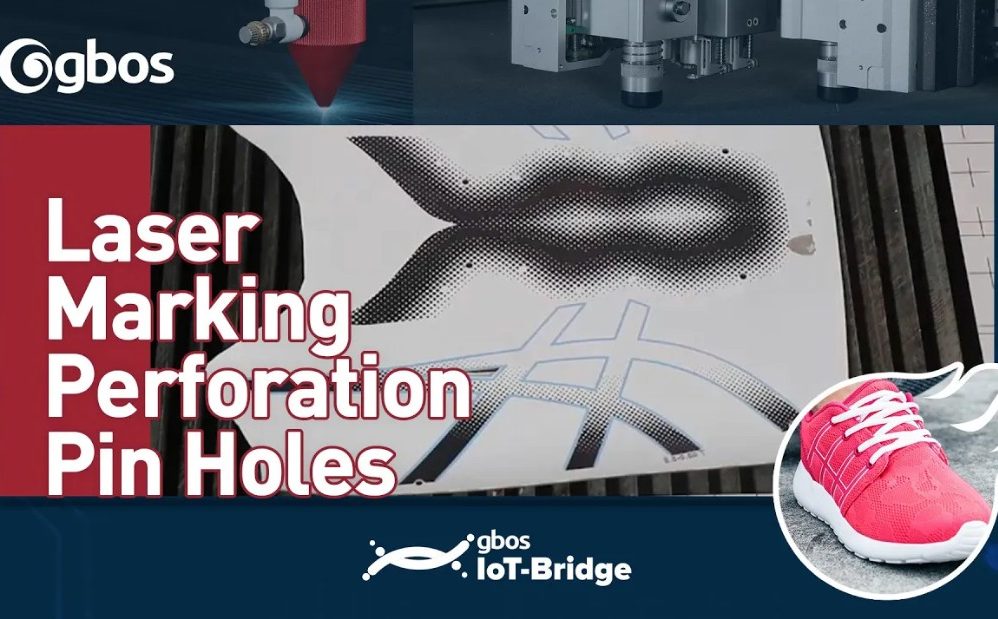

CCD Automatic Extraction① Effectively identify area: 150mm*120mm. ② Automatic tracking and cutting. ③ Replace manual soldering iron. ④ High precision recognition and cutting label (Edge cutting).

CCD Automatic Extraction① Effectively identify area: 150mm*120mm. ② Automatic tracking and cutting. ③ Replace manual soldering iron. ④ High precision recognition and cutting label (Edge cutting). -

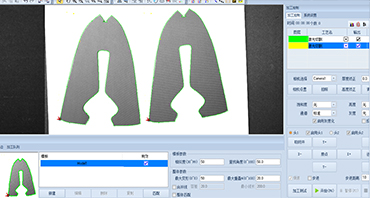

CCD/SCCD Transformation Matching Multi- templates① According material transformation condition, automatic deformation cutting. ② Multi- templates cutting can be set.

CCD/SCCD Transformation Matching Multi- templates① According material transformation condition, automatic deformation cutting. ② Multi- templates cutting can be set. -

CCD Deformation Matching Cutting① According material transformation condition, automatic deformation cutting. ② Camera follow the label transformation do grapth matching. ③ Solve the problem of cutting edge unsmooth.

CCD Deformation Matching Cutting① According material transformation condition, automatic deformation cutting. ② Camera follow the label transformation do grapth matching. ③ Solve the problem of cutting edge unsmooth. -

High EffectiveCompare to normal CCD cutting machine, GBOS smart camera laser cutting machine speed increased by 40%-50%. Optional glass laser tube 70W,80W,100W, 130W meet any of your requirements.

High EffectiveCompare to normal CCD cutting machine, GBOS smart camera laser cutting machine speed increased by 40%-50%. Optional glass laser tube 70W,80W,100W, 130W meet any of your requirements.

Expand More +

Functions & Modules

-

Enabling asynchronous cutting of different shapes, improving production efficiency and reducing production time.More Details

Enabling asynchronous cutting of different shapes, improving production efficiency and reducing production time.More Details -

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details -

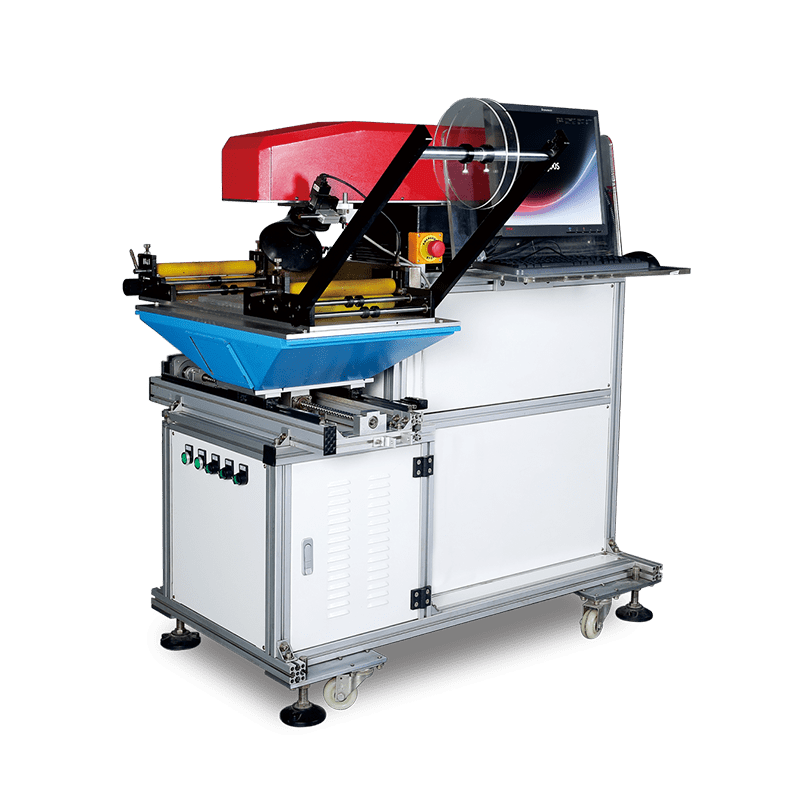

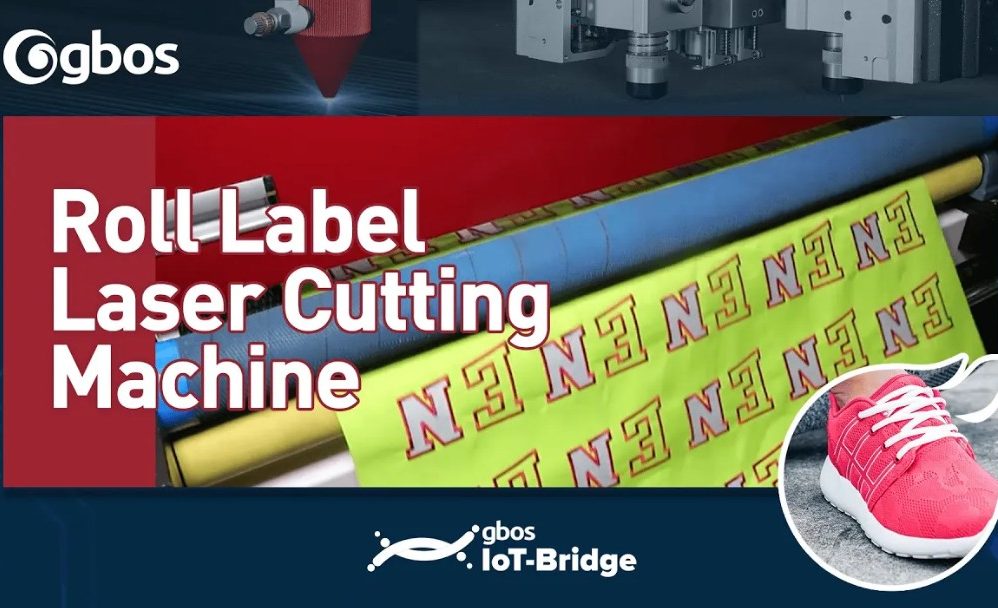

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details -

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details -

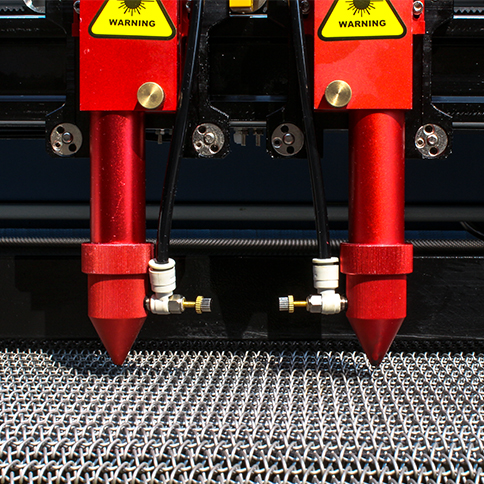

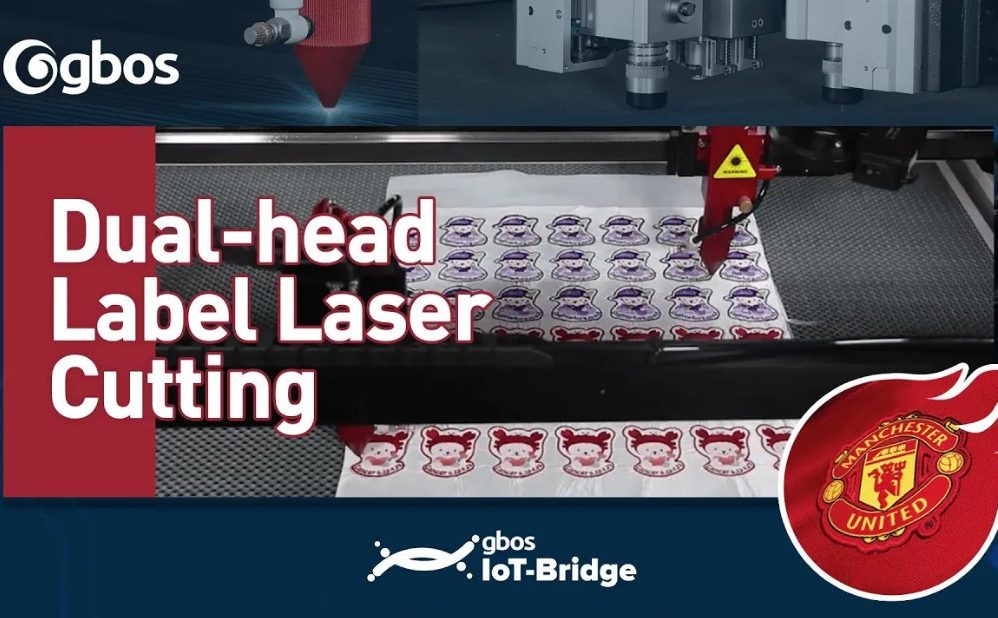

Dual laser head on a single track, greatly improve efficiency.More Details

Dual laser head on a single track, greatly improve efficiency.More Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: