Stock Code: 870145

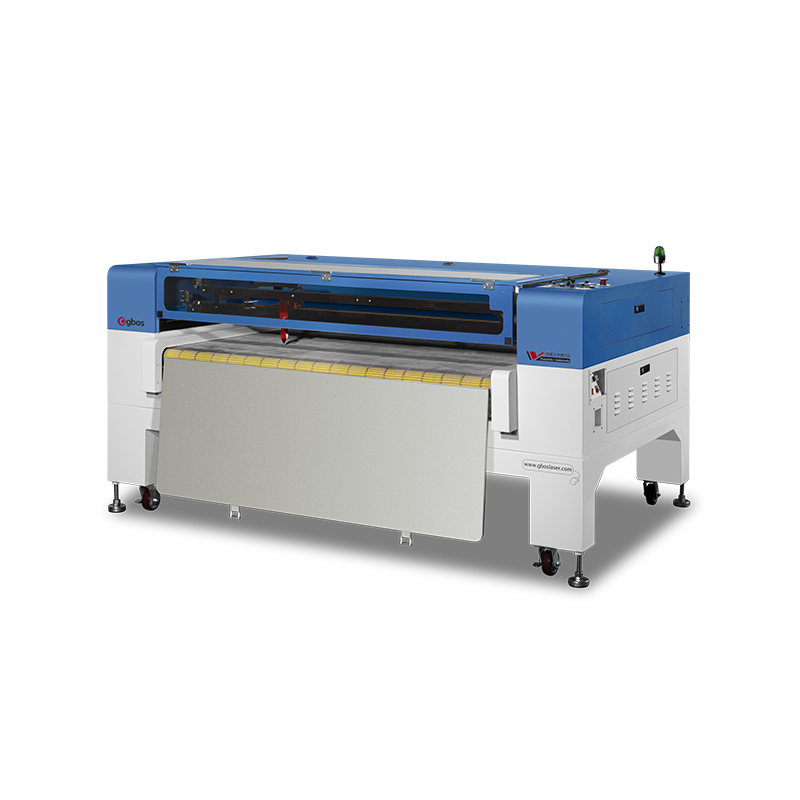

GH1610-AT

Auto Feeding Laser Cutting Machine

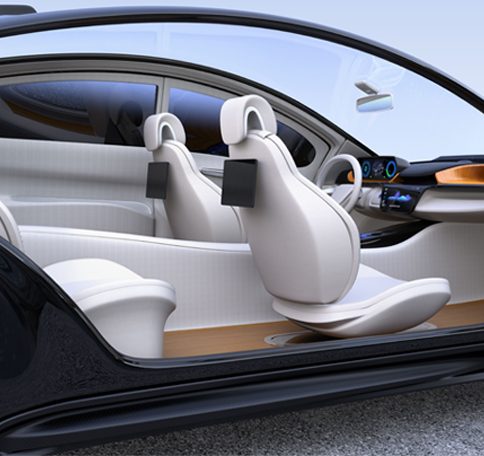

For all kinds of flexible materials (fabric, shoe components, garment accessories, automotive interiors, etc).

Production in high standard.

Big design with segmented cutting.

Integrated design for feeding system.

Camera Positioning. Automatic with double (Optional).

Intelligent layout (leftover material cutting, material saving).

Intelligently follow your direction, double heads working interactively.

| Working area | Gross power | Laser power | Power supply | Dimension | Overall weight | System compatible format |

|---|---|---|---|---|---|---|

| 1600*1000mm | ≈1800W | ≤90W | 220V/10A, 50Hz or 60Hz | 2250x2100x1150mm (LxWxH) | 535KG | Windows XP/7/8/10, AI, PLT, DXF, DST, BMP, JPG, JPEG, PNA, TIF. |

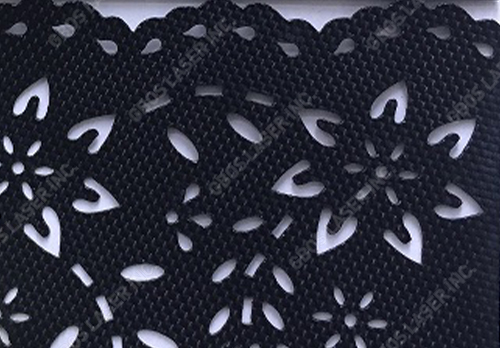

Materials & Samples

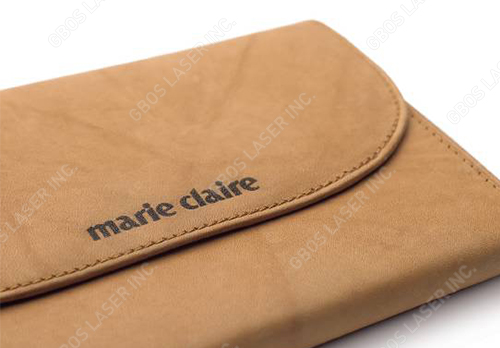

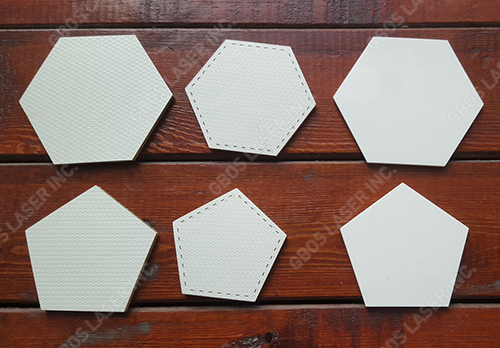

- Leather

- Shoe Accessories

- Synthetic Material

- Garment Accessoreis

- Handbag/Wallet Accessories

- Automotive Interior

Expand More +

Expand More +

Expand More +

Functions & Modules

-

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details -

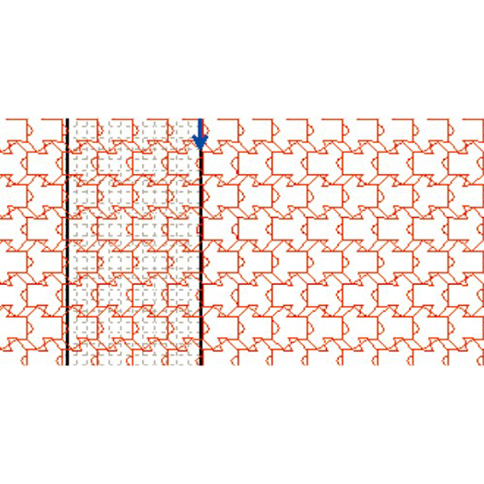

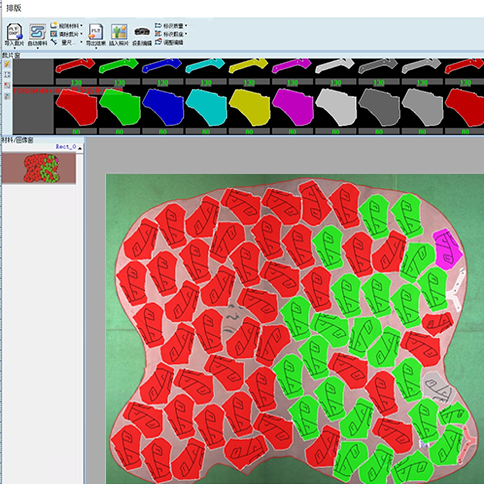

Intelligent nesting system, which is used for regular materials and can improve utilization and reduce material waste.More Details

Intelligent nesting system, which is used for regular materials and can improve utilization and reduce material waste.More Details -

Auto-feeding system with multi roll shelf. Support feeding of 6 rolls at the same time.More Details

Auto-feeding system with multi roll shelf. Support feeding of 6 rolls at the same time.More Details -

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: